They are regularly used in most cement plants and in a lot of other sectors of activity, throughout the production process. Here is how the new AIRCHOC air cannon can meet the needs of energy production in particular:

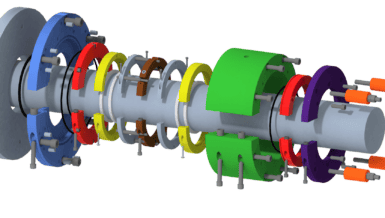

The AIRCHOC® air cannon acts preventively on the product thanks to regular firing. It is an economical solution that uses air only when the shots are activated. With a wide range (tank capacity from 4 liters to 400 liters), this solution can be adapted to many bulk areas. In recent years, the air cannon has been in great demand from energy suppliers, incineration centers, and biomass boiler installers.

What solutions does AIRCHOC bring to the boiler room?

AIRCHOC® air cannons, placed at the level of boiler feed chutes, ducts, heat exchangers, or convection surfaces, prevent product accumulation and contribute to continuous heat production. This air cannon cleaning system is highly efficient and complements the soot blowers. It enables operators to supply energy without the risk of breakdowns due to unforeseen maintenance.

The AIRCHOC® solution can also be found throughout the process, particularly in economizers, superheaters, hoppers under filters, and at the very end of the process, especially on fly ash silos, or on incineration fly ash silos. The desired function of this equipment is to avoid residue deposits creating irreversible clogging in the more or less long term.

Example with IDEX, an operator biomass boiler in France

CONTEXT :

- Boiler power : 48.5 MW

- Fuel : Biomass 150,000 tons/year => 69m³ of biomass / hour

- Forestry pellets

- Forestry shreds

- Related sawmill products

PROBLEM :

IDEX has problems with the clogging of the bundles of these 2 economizers (eco 1.1 + eco 1.2). This reduces the passage of smoke that must be treated for the use of the biomass boiler. This customer used to use chimney sweeps on its boiler. But these chimney sweeps are not efficient enough and are expensive to maintain.

SOLUTION :

4 AIRCHOC AC520HFP air cannons were installed on the first row of beams on economizer 1. The choice of a 200-liter tank allows for a large volume of air to sweep all the installed beams. The customer has adopted the firing frequency of 1 gun every 15 minutes.

RESULT :

IDEX is satisfied with the result because the flue gas treatment circuit is clean, and the boiler can produce normally. Moreover, by changing the cleaning solution, he saves on his maintenance.