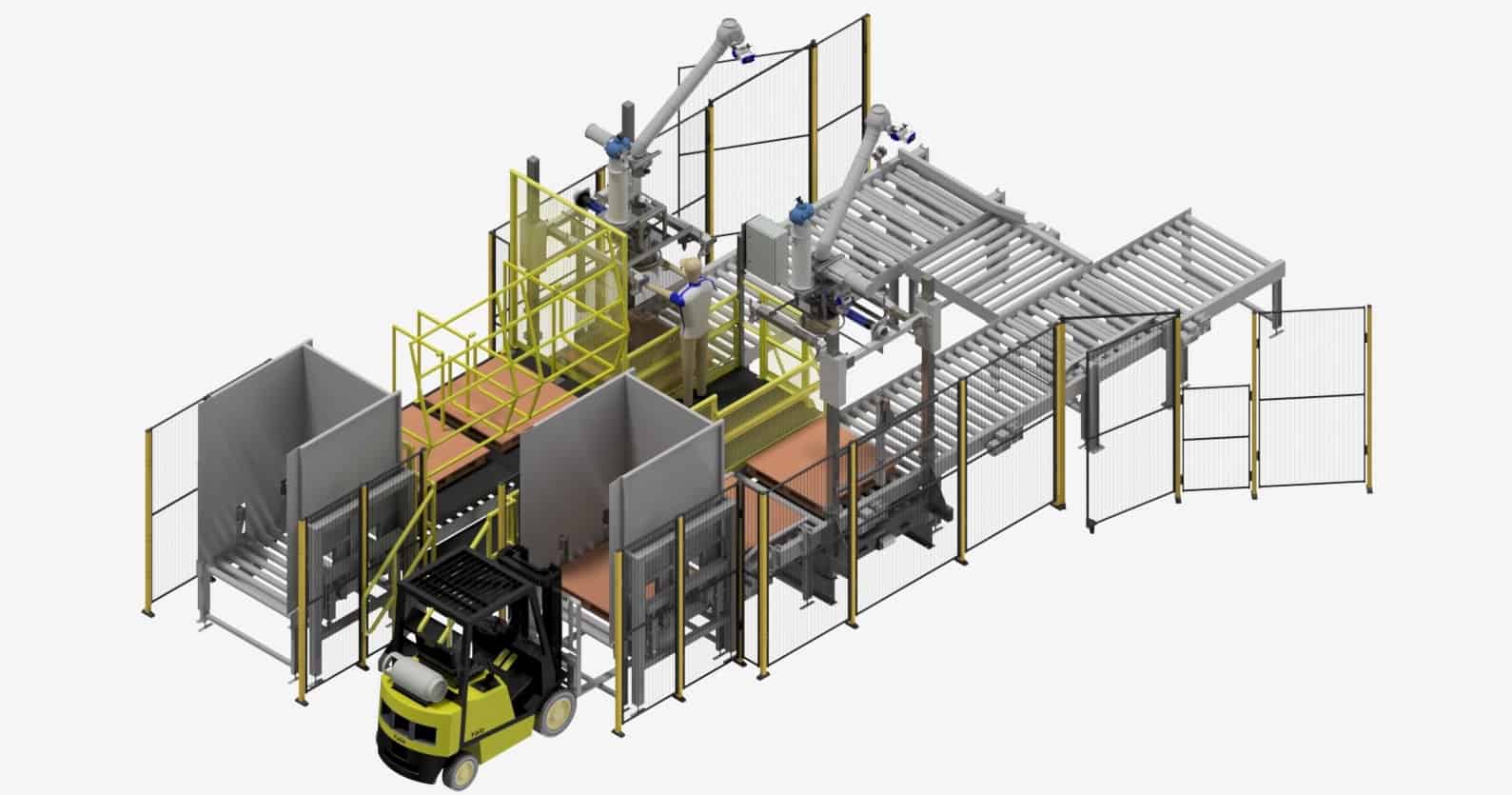

This system is specifically designed for filling big-bags in a high-care environment, where no pallet is used. With, among other things, the integrated belt conveyor, triple sealing and the absence of hydraulics, this is a very well thought-out Big-Bag filling solution.

Features

- Filling of big bags under very careful conditions, without pallet.

- Sealed filling process: triple sealing with spout stretching technology.

- Big-bag compaction and weighing integrated in one position.

- Blow-in system to blow the big bag into shape at start-up.

- No hydraulics in the high-care area.

- Hygienic design according to EHEDG standards.

- Automatic hook movement for better ergonomics.

- Automatic unloading of big bag loops.

- Integrated belt conveyor, lifting table and vibration unit.

- Produced by Dinnissen: designed, built and tested in-house.

Advantages

- Food-safe.

- No dust contamination.

- Optimal compaction.

- Stable ‘high’ big bags without gas inclusions.

- Guaranteed oxygen level (< 0.5%).

- High capacity.

- Good ergonomics