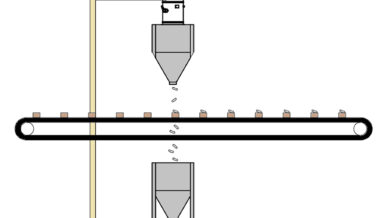

Process equipment manufacturer Volkmann USA, Bristol, PA, has unveiled its 2022 lineup of Volkmann Multijector® vacuum pumps. The foundation of the company’s pneumatic vacuum conveying systems, the Multijector vacuum pumps feature patented technology based on the venturi principle that generates the high amounts of suction air and negative pressure needed to transfer powders and other bulk solids gently in dense phase. The innovative vacuum pumps operate with compressed air while eliminating the rotating parts, motors, lubricants, and heat and ignition sources common to electromechanical pumps. A key part of removing any potential sources of ignition, the Volkmann Multijector vacuum pumps allow explosion-proof, ATEX-certified conveying, even when conveying fine, ignitable powders and combustible dusts.

Installed in hundreds of solids processing facilities worldwide, the line of Multijector vacuum pumps comprises 12 different models in a choice of materials and optional configurations to suit nearly any material transfer requirements. The Multijector G Series four-stage ejector vacuum pumps and the Multijector MX Series three-stage ejector vacuum pumps offer a wide range of airflows to meet the requirements of each pneumatic vacuum conveying system.

The Volkmann Multijector line of vacuum pumps are offered individually and with companion conveying systems. The vacuum pumps and conveyors may be tested in full size in the company’s Bristol, PA test facility to simulate actual operating conditions.