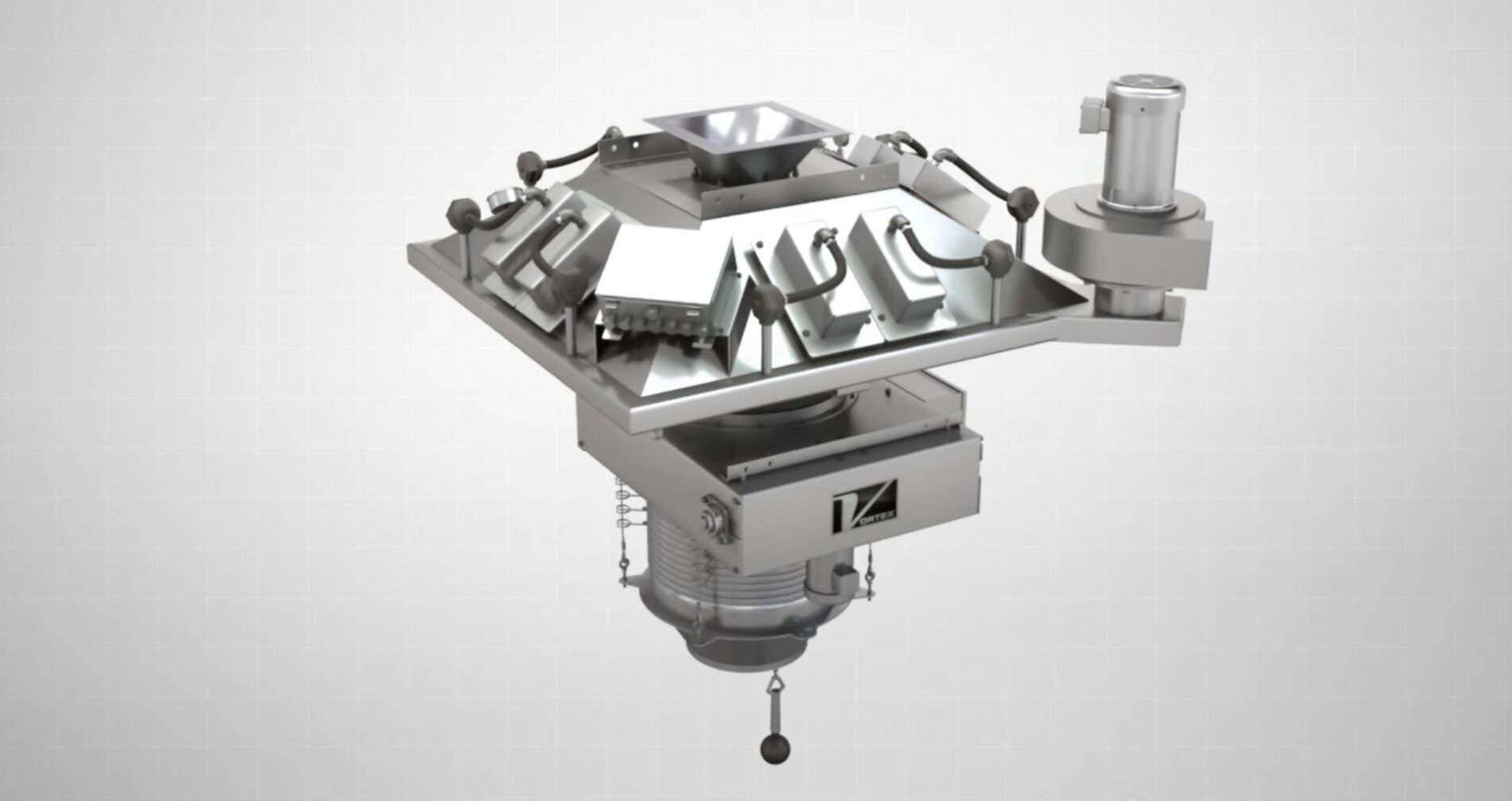

Economical and versatile, the Vortex Roller Gate is the premium choice for handling dry bulk material in gravity flow applications where positive material shut off and dust tight sealing are required.

The gate valve’s live-loaded seals extend the service life by compensating for wear. The seals provide an excellent material seal across the gate and to atmosphere.

These seals are easily replaced without removing the valve from the processing line. The Roller Gate utilizes easily accessible, nylon cam-adjustable rollers instead of blade guides – a feature that is critical to avoid material packing. Vortex Roller Gates are ideal for many dry material applications such as mixing and blending. The Roller Gate can be applied to shut off or meter the flow of fine and moderately abrasive powders and small to large granules or pellets. It also handles sticky materials, horizontal or vertical valve orientation, and is ideal for the food, cement, chemical, plastics, and textile industries.