Both solutions rely on exceptionally high measurement resolution and frequent load sampling for accurate rate measurement and control Thayer Scale’s unique technologies mitigate the known mechanical factors, such as foundation distortion and tight process connections, that contribute to inaccurate weight measurement and poor measurement repeatability in loss-in-weight feeders. Thayer Scale’s proprietary Force Measurement Suspension System (FMSS) is an interposed active structure, consisting of one or more articulated members, placed between the load receptor (hopper, platform, weigh suspension, etc.) and a load cell. FMSS functions as a force filter; it discriminates between net load measurement forces and all other undesirable extraneous forces. In standard weighing systems, load cells often interpret vibration as weight variation. FMSS technology makes load cells virtually immune to the detrimental effects of vibration.

Thayer Scale employs FMSS in the following solutions:

- Constant sensitivity platforms (flexure and cable scales)

- Graded sensitivity weighbridges (conveyor belt scales)

- Lateral torque transmitting devices (Model “D”)

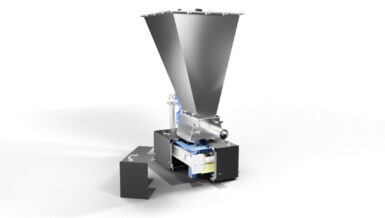

Thayer Scale offers a broad array of vibratory feeders. Outfitted with Thayer Scale’s FMSS cable scale, LIW feeders gently handle a wide range of particle shapes without causing damage or degradation to the product. They provide a uniform, non-pulsating flow of difficult-to-discharge materials (fiberglass strands, products with low melt points, fragile materials such as dehydrated fruit additives, etc.) over a wide operating range without the need to make any mechanical adjustments over the entire flow rate range.

Design options allow vibratory trays to dispense material at a single point or spread across a wide band. Thayer Scale models offer a unique, counter-rotating agitation system that gently dilates material for reliable material flow through the weigh hopper to the vibratory tray. At the heart of any gravimetric feeder is its scale system. Thayer Scale’s patented Force Measurement Suspension System “FMSS” cable scale technology is the most rugged and forgiving Load Cell weighing system available on the market.

Benefits of Thayer Scale’s patented FMSS cable suspension system include:

- Field-adjustable, mechanical tare-balancing of dead loads (typically as high as 200 times net loads) to maximize measurement signal

- Immunity to support-structure deflections and process vibration

- Accessibility for load cell for inspection and removal

- Pneumatically-operated automated test weight lift and storage mechanism to simplify the application of test weights

- Zero-shifting reduction

- Measurement not affected by off-center or overhung loads (i.e., long discharge augers)

- Feeders that may be moved frequently without damage or the need for re-calibration

- Inherent self-alignment to gravity

- No susceptibility to shock and impact loads

- 1000 percent mechanical overload protection

- Optimal access location of load cell for easy inspection or removal

- Simplified test weights application for calibration checking

- Reduced signal velocity and acceleration under dynamic conditions