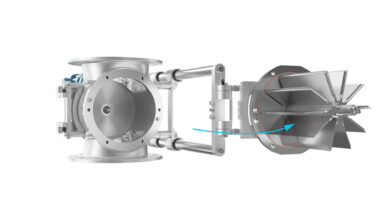

Utilizing one of 23 onsite CNC machines, the Meyer HDX rotary airlock valve, for example, is precisely machined to accommodate very tight clearances. Clearances are customized to meet the needs of a spectrum of specific applications and temperatures.

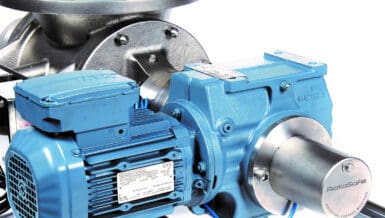

Libertyville, IL-based, Meyer Industrial Solutions Division produces premier system components for dry bulk material processing equipment, pneumatic conveying, and dust collectors. Precision engineered and manufactured in America, Meyer is known for its robust rotary valves, sanitary airlock feeders, flap gates, knife gates, screw pumps, gravity diverters, and more.