The devices correct belt misalignment, prevent material loss and avert such problems in the future. In this way, users can increase the lifetime of their systems and significantly boost productivity. The costs of maintenance, new conveyor belts, and installation are reduced. Flexco will be showing the EZP1 precleaner and other systems at Booth L2.

The EZP1 series is easy to install and maintain, and they deliver excellent cleaning results. Users now have the choice of an additional polyurethane blade from. Since belts can be subjected to hot as well as cold temperatures, Flexco has developed a bright yellow high-temperature cleaner blade that allows continuous operation up to 135°C and brief peaks up to 163°C. The newcomer to the range is the deep red ultra-high-temperature cleaner blade, which performs reliably at up to 230°C. Belts may be exposed to such high temperatures when transporting coal, clinker or cement. Regardless of the use, Flexco cleaner blades are highly durable, so they don’t have to be changed as often as comparable competitor products. That significantly reduces downtimes and material costs.

In Montpellier, Flexco will also be showing the advanced EZP1T precleaner. The “T” stands for torsion tensioner system. This component requires less space than the spring tensioner system in the standard version. Like the EZP1, the EZP1T is easy to install and quick to service. The system is optionally available in corrosion-resistant steel. Conveyor system operators can choose from four different PU blade versions, including designs for high and extremely high temperatures and a chemical-resistant version made of FDA-approved material.

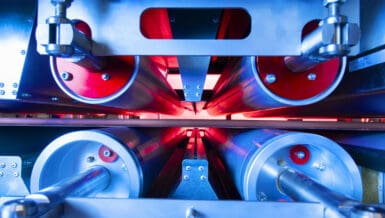

Flexco will also be showing industry visitors its PTEZ belt trainer, which is suitable for light to heavy applications and for reversing belts up to 2,100 mm in width. Conveyor system operators can also use this system on belts with worn or damaged edges – and thanks to the simple design of brackets and components, the station is quick and easy to mount. One special feature of the PTEZ is the roller, which is coated as standard with more wear-resistant polyurethane. Competitors usually charge more for this feature. Users can also choose an economical version with a rubber instead of polyurethane coating.

FLEXCO at SIM: Booth L2