From chemical applications to sanitary design processes, loading large-scale mixers with open and close hatches, often six to seven feet tall, has its challenges. Traditionally, processors have used manual and mechanical means to load mixers. Today, more and more processers are turning to vacuum conveying systems that help them mitigate safety hazards, reign in fugitive dust, eliminate hours of laborious sanitation protocols, and to combat rising materials costs.

Increased safety is one of the more common reasons for processers seeking solutions from vacuum conveying applications. Examining the staggering costs associated with workplace injuries, it is clear that manufacturers and processers understand the financial benefits of employing vacuum conveying systems to create a safer working environment for workers. Workplace injuries cost manufacturers 146.54 million dollars per week according to Liberty Mutual’s “2019 Workplace Injury Index: Manufacturing”.

A Bureau of Labor Statistic (BLS) news release from November 4, 2020, “Employer-Reported Workplace Injuries and Illnesses – 2019”, reported that the manufacturing sector accounted for 15 percent of the 2.8 million total reportable cases (TRC) of nonfatal injuries and illnesses in the workplace during 2019. According to the news release, among the 10 occupations listed with the highest days away from work (DAFW) cases, laborers and manual freight, stock, and material movers had the “highest” cases with 64,160. The good news is that the manufacturing industry was the only sector with a “statistically significant change” in TRC between 2018 and 2019, (down from 3.4 to 3.3).

Manual materials handling is hazardous. Manual loading of mixers typically requires operators to climb stairs to a mezzanine to load materials. This arrangement presents fall, exertion, repetitive motion, and awkward positions hazards. In addition, manual loading of bulk solids and powders into a vessel creates a cloud of dust that can be hazardous, get into operators’ breathing zones, and settle on nearby equipment.

Although there are still many processors that opt for manual transfer of ingredients into mixers, some use mechanical conveyors as a remedy for the associated hazards. Dollar-for-dollar mechanical conveyors are less expensive to operate than vacuum conveyors because they require only a power source, unlike vacuum conveyors that need a power source and an air source. The main differentiator between mechanical and pneumatic conveying is that mechanical conveying–including conveyor belts, horizontal motion conveyors, aero-mechanical, flexible screw, and bucket elevators – use a mechanical device that is in direct contact with transferred material. Pneumatic conveying uses gas (usually air) to transfer suspended material through tubes.

Secondly, pneumatic conveyors can accommodate changes in direction and elevation if needed. While minimizing changes in direction is desirable, a pneumatic conveyor can be designed to convey materials in the X-, Y- and Z-axis without transfer points or additional motors and controls. Mechanical conveyors have much higher maintenance costs than vacuum conveyors because mechanical conveyors have several moving parts, bearings, and drives that need regular maintenance, making them more susceptible to unscheduled downtime. Mechanical conveying is sometimes more suited for specific applications, and routinely has lower capital costs; however, the life of the equipment and associated costs typically offset any difference.

Vacuum conveying is by far the most hygienic conveying method for dry bulk powders and solids. The inherent nature of fully enclosed vacuum conveying systems prevents loose powder and dust from becoming airborne contributing to a cleaner and safer environment all around. The enclosed nature of vacuum conveyors also assists in compliance with the FDA’s Food Safety Management by preventing both intentional and unintentional food contamination events. Vacuum conveying systems are fairly simple, consisting of five basic parts, a pick-point where material enters into the conveying system, convey tubing which transfers material between equipment, a vacuum receiver (typically equipped with a filter, and therefore often referred to as a filter receiver) which is an intermediate holding vessel for materials, a vacuum source that powers the system, and a control panel that tells the system how to operate.

The primary use of vacuum conveyors is to transfer materials to-and-from processing or packaging equipment but another use that is becoming more common is to reclaim materials for reuse. When one thinks of dust collection, the assumed idea is to capture fugitive dust and debris as a waste product. However, ancillary equipment and innovative system engineering turns the task of straightforward dust collection into fully integrated systems designed to reclaim expensive ingredients and preserve quality formulations. Broadly used in industry, especially where manual powder handling occurs, dust collection systems improve air quality, increase worker safety, protect equipment from dusts that can hinder operation and reduce labor cost associated with housekeeping.

In an ongoing effort to amplify safety and get ahead of rising raw materials costs, a major paint manufacturer needed to solve a dust issue occurring during the mills process where operators manually add multiple fine powders to liquids to produce latex, oil, or water based liquid paint. The paint producer was handling approximately 3000 pounds of powder per batch through a combination of super sacs and 50 pound bags and the purpose of this project was to control the dust and return the captured dust into the process. In the paint industry, approximately 50 percent of costs are from raw materials and the paint producer wanted to account for that material—not just to control costs, but also to preserve product quality by ensuring all formulation weights made it into the process.

There are several powders that make up a paint’s formulation—which are mostly fine powders—and one of the most challenging is Titanium Dioxide which has a reputation of sticking, bridging, plugging, clogging, and ratholing. Without an optimized system, the dust collection system could experience a backup. The vacuum conveying system for this application collected 200 pounds per hour–which is on the low end for pneumatic transfer systems but considered a higher volume system since it was just collecting airborne dust. The dust collector outlet has a rotary airlock that discharges into a pipe where the vacuum conveyor system sucks the discharged material into the convey line through a flexible hose to a compact receiver that discharges back into the mix tanks.

The conveying system includes a compact filter receiver with a single cartridge filter that was able to fit in the headroom directly above the tank because of its smaller size; and, the transitions to go back into the tank were customized for the process. The system uses a compact regen blower with low-horsepower motor and was easily incorporated into the existing system. Now the paint manufacturer is able to reclaim expensive materials while eliminating a respiratory hazard that had previously required operators to wear masks. Because increased safety is a major factor in companies investing in vacuum conveying systems, vacuum conveyor manufacturers are engineering innovative systems with safety in mind.

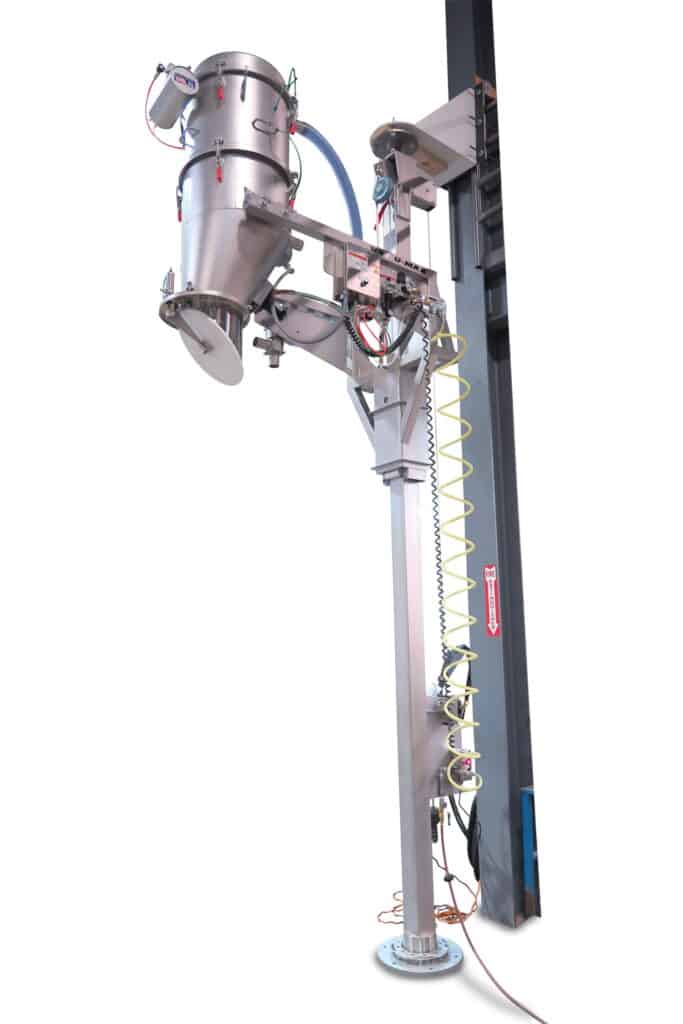

Even with the most sophisticated vacuum conveying systems, equipment that is located out of reach still poses hazards for operators who need to clean or service vacuum conveying equipment that is permanently installed above process machinery. Mobile and column liftconveyors are complete conveying systems that raise and lower vacuum receivers in order to load mixers, reactors and other processing equipment and then bring the vacuum receivers back down to ground level for cleaning or sanitizing.

Column lift conveyors utilize an electric lift mechanism with a remote pendant, controlled by an operator standing a safe distance away, to raise and lower vacuum receivers above mixers, blenders, reactors, and other process vessels with fill ports 15 feet or more above the floor. These systems, with top and bottom anchors are able to load side-by-side process vessels from paper bags, drums, IBC’s, boxes, bulk bags, silos, storage containers and feed bins. Mobile conveying systems operate in the same fashion as column lift conveyors, but are portable, movable with one operator, and able to service multiple process vessels at varying discharge heights. When not in use, operators can roll these vacuum conveying systems from the work area to save on floor space.

These types of units are compatible with OSHA’s Walking-Working Surfaces standard to protect against falls and slips; and back injuries from repetitively carrying bag and boxes up the stairs to load or clean equipment. The ability for operators to bring equipment down to floor level for cleaning reduces downtime, labor costs and potential injury costs. Mobile and column vacuum conveying systems, when constructed within FSMA sanitation regulations, are ideal for food, nutraceutical and pharmaceutical applications.

When production throughput demands a high level of cleanliness with minimal labor and time, clean-in-place (CIP) equipment can eliminate hours of downtime. Cleaning downtime can be devastating to a company—sometimes taking one to two days to tear everything down and clean it. CIP is a procedure designed to clean all or parts of a process system without needing to completely disassemble or move equipment. CIP is the strategic placement of spray balls, or nozzles, within vessels that circulate water and cleaning solutions. It is automatic and has consistent performance.

Although CIP has been around for a while, it is still a leading-edge technology, and is gaining traction in the food, pharma, nutraceutical, and cosmetics industries—so much so that the acronym is being used as a verb these days with customers saying they need “CIPable equipment.” In CIP vacuum conveying systems, operators remove filter elements and replace them with insertable spray ball assemblies for cleaning saving on time and making the task safer for workers. When a nutraceutical beverage producer landed a large contract, it needed to increase throughput and reduce the 8-hour cleaning cycle that occurred between batches in order to meet demand.

To achieve this, the beverage producer replaced its 90 cubic foot mixer with a 160 cubic foot CIP mixer, a CIPvacuum receiver and CIP bag dump station. These changes reduced sanitation from 8 hours to 1.75 hours—gaining 6.25 hours of production and reduced labor costs every day. The CIP system also averted the need to develop a confined space plan with the new larger equipment since the sanitation team didn’t need to enter the process vessel for cleaning.

Good sanitary vacuum conveyor design includes a package of simulated spray ball positioning and surface coverage documentation. Working with a vacuum conveyor manufacturer with decades of experience and a variety of technologies such as vacuum conveyors, aero mechanical conveyors, and flexible screw conveyors ensures processors get the best possible materials transfer system that works within their process and business parameters.