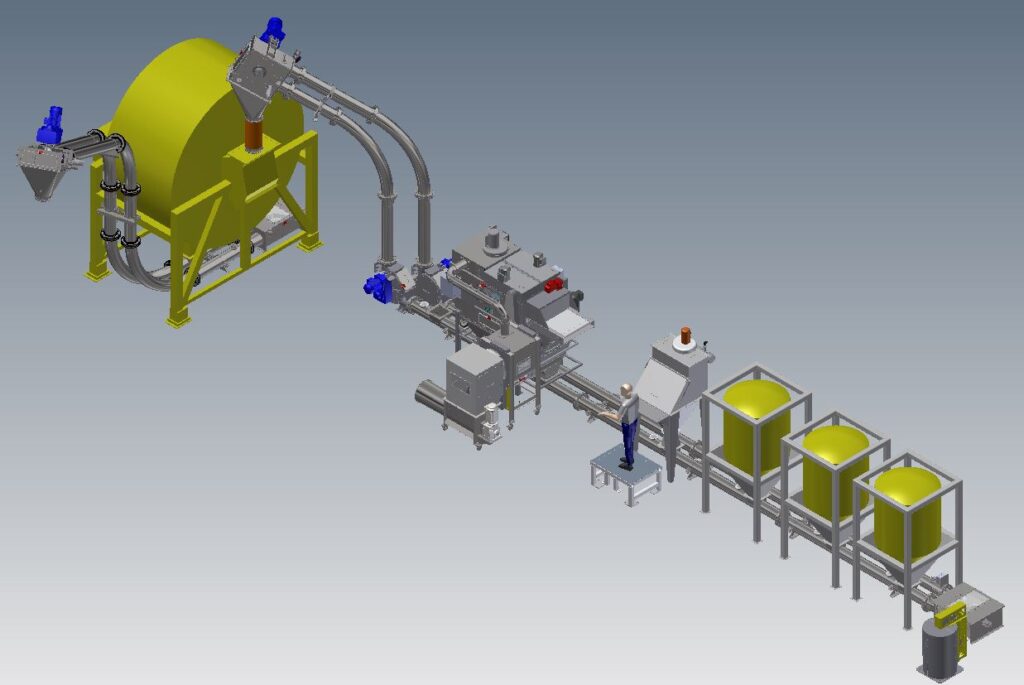

Powders or pellets supplied in bulk bags, totes, drums and 25kg or 50kg bags are handled in a sanitary manner using tubular chain conveyors. These USDA certified conveyors move product within a pipe using sanitary product contact surfaces.

Automatic bag slitters to USDA sanitary design are used to open and empty bagged ingredients in 25kg or 50kg bags. It is their preferred solution to efficiently move powders at a high rate into storage, mixer and blender, and upstream for batch ingredient metering.

Sanitary Automatic Bag Slitting:

The MINILux automatic bag slitter provides a negative pressure, and sealed bag slitting, opening and emptying chamber. This prevents air borne dust from leaving the slitting process and prevents outside contaminated air from mixing with ingredients. Bags are brushed clean before any ingredients inside the bag is released.

Automatic bag slitters deliver high bag opening and emptying rates of 5 to 6 bags/min. instead of 1 to 1.5 bags/min. in a manual process. Automated slitters deliver material at 2.0 to 2.5% higher yield over opening bags manually. Bag emptying efficiencies of 99.95% to 99.99% are commonly achieved with automatic bag slitting. When using expensive ingredients in high volume operations, this feature becomes extremely important in minimizing expensive waste.

For safe and sanitary handling of bagged powders, the automated bag slitting lines is made up of a bag cleaner, conditioner, slitter and conveyor to transfer free-flowing powder ingredients. Slitters automatically adjust to bag size, format and material. Bags of multiple sizes, designs and materials are handled by these slitters without having to make any slitter set up changes. This is important for batches where multiple 25kg or 50 kg bagged ingredients make up a recipe and are mixed or blended into finished product.

Sifters or screens are always used downstream to capture any impurities prior to dry powder packaging or prior to blending the powders with liquids. Automatic bag slitting lines are designed for both food and pharmaceutical applications. They are adopted where bag processing volumes are high, or when the cost or value of the bagged materials is high.

Automatic bag slitting lines are set up to optimize mixer or blending operations for high productivity with minimal waste while adopting a dust free and sanitary design.

Dust Free, Sanitary Conveying

Powders are conveyed in a sanitary manner using USDA certified tubular chain conveyors. This technology is preferred for its compact, sealed transfer, and dust free design The tubular chain conveyors utilize pivoting discs coupled to a flexible chain moving inside a stainless-steel pipe to convey product up to 2,200 Ft3/Hr. It delivers materials from single or multiple inlets to single or multiple outlets. They run dust free and consume very little energy. The product inside the conveyor is protected from external contaminants and is delivered without releasing fines to the atmosphere.

These conveyors are used where dust and odor must be kept within the system and not vented to atmosphere therefore keeping work areas clean and safe. When in proximity to personnel work areas, tubular chain conveyors maintain a dust free workspace while protecting the ingredients or products they convey.

Tubular chain conveyors accommodate multiple layouts, and throughput options handling product without degradation. Conveyors are built in stainless-steel to match the product contact requirement set by the application and material requirement. Automated Clean-In-Place technology to deliver sanitary wash downs is used to maintain sanitary surfaces.

The design emphasis of pharmaceutical specific automatic bag slitting and material conveying is to efficiently move dry or wet ingredients while protecting them from external contaminants in a dust free and sanitary manner.

Highlights of LUXME Solutions:

46 Years of Proven Expertise as manufacturers of Pharmaceutical and Food safe automatic bag openers, cleaners, crushers, elevators, lump breakers, and tubular drag chain conveyors.

MINILux Bag Slitters are small and compact. They are designed to replace the existing manual dump stations to reduce risk of worker exhaustion, accidents and product contamination from external contaminants entering through the open bag inlet hoppers. They deliver financial benefit from high productivity and high product collection efficiency.

CIP SaniLux Sanitary Conveying Technology that clean in place, completely eradication pathogens and allergens from internal and product contact surfaces. This patented one-hour sanitizing process uses a mobile chemical dispensing unit and hot air supply module to fully sanitize and dry the conveyor to make it available to production with minimal downtime.

Tubular Chain Conveyors and Automatic bag Slitters comply to the USDA food handling machinery design requirement. Product contact is of a sanitary design for handling pharmaceuticals related products. These have included egg embryos, vitamin ingredients, and dry vitamin powders transferred to the pill pressing step.

With over 45 years of automatic bag slitting and tubular chain conveyor expertise, Luxme International designs and manufactures custom solutions where safe and sanitary conveying and bag emptying is a priority.