It keeps plant personnel safe from climbing silos, makes purchasers more effective, and improves processing efficiency by always having the right resins on hand.

ResinView® can be accessed anywhere there is an internet connection—a control room, office, remote location such as corporate headquarters, or from home.

Users can set up ResinView® to view data the way they need it, such as by alert status, percent full, material, or location.

Simplicity and Savings

ResinView® easy to work with and highly affordable. The BinCloud®-based subscription program is based upon the number of silos being monitored—just several dollars per month per silo. ResinView® does not require an IT expert to install or manage the program. Updates are performed by BinMaster, who also provides the necessary training and ongoing support.

Streamline the Supply Chain

ResinView® inventory management software sends automated alerts via text or email. This helps plants ensure that silos or hoppers never run empty and interfere with production. Purchasing can monitor trends, place orders, and view order history. Delivery trucks can be scheduled with confidence, knowing the entire load will fit into the silo. Providing resin suppliers access using vendor managed inventory allows them to be proactive in ensuring supplies are adequate to prevent shortages.

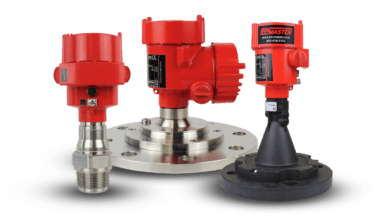

Level Sensors Deliver Accuracy

ResinView® is compatible with many types of level sensors. Granular, powder, flake, or liquid forms of resin may require different types of sensor technology. Non-contact radars, SmartBobs, and lasers are often used for resin monitoring. No power to the bin, no problem—battery powered sensors make installation easy. ResinView® is compatible with sensors using analog or 4-20 mA, Modbus, or HART outputs.

Any Type or Size Operation

ResinView® can be used by compounders, extruders, injection molders, rotational molders, and refiners—any operation that is storing resin pellets, powders, flakes, or liquid resins or plasticizers. It can also be used to monitor inventory levels in pellet dryers, day bins, and coolers. ResinView® is highly scalable for a single location or multiple sites and any number of silos.

ResinView® Benefits for the Plastics Industry

- Prevents production outages and reduces excessive safety stock

- Supplier collaboration using Vendor Managed Inventory

- Real time data available to staff on site or working remotely

- Inventory is updated with each sensor measurement

- Historical data to forecast upcoming resin needs

- Silo inventory available on a phone, tablet, or PC

- Eliminates climbing silos to measure inventory