1. A Major Industrial Challenge for the Sugar Industry

The sugar industry plays a strategic role worldwide. Sugar production—mainly derived from sugar cane (nearly 80% of global production) and sugar beet—represents more than 140 million tons per year, concentrated across a dozen major producing countries. In Europe, the beet sugar sector remains a historical pillar of the agri-food industry, supported by a dense network of sugar plants, storage silos, and packaging facilities.

However, this industrial concentration is accompanied by a major and often underestimated risk: the risk of sugar dust explosions. Every stage of the process—transport, elevation, storage, and bagging—can generate clouds of combustible dust, potentially leading to severe accidents with serious human, material, and economic consequences.

2. Sugar: A Food Product… Yet Also Explosive

When dispersed in the air as fine dust, sugar has all the characteristics of an explosive combustible material. When confined and exposed to an ignition source (mechanical overheating, sparks, friction, electrical failure), it can trigger a primary explosion, followed by secondary explosions that are often far more destructive.

The most critical areas in a sugar plant are well known:

- bucket elevators,

- conveyors and pneumatic transfer systems,

- storage silos,

- duct and piping networks,

- packaging and bagging installations.

Bucket elevators, in particular, represent high-risk equipment due to dust accumulation, confined volumes, moving mechanical parts, and continuous product flow. Industrial history shows that these units are frequently at the origin of explosion events.

3. Conventional Protection Measures in Sugar Plants

For many years, sugar plants have relied on conventional prevention measures such as enhanced housekeeping, dust extraction, grounding, and explosion venting. These solutions play a key role in risk reduction. However, depending on the site configuration and production constraints, complementary protection technologies may be implemented to further enhance safety and limit the consequences of an incident. This is where explosion suppression systems become particularly relevant.

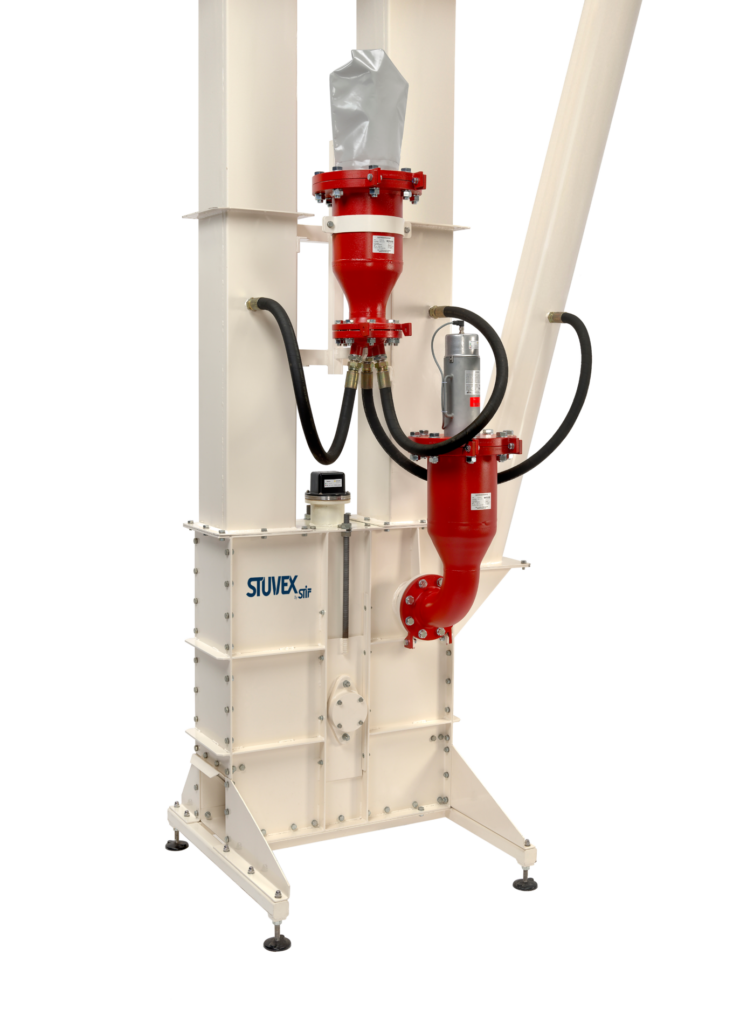

4. The STUVEX Flash Suppression System and Chemical Barrier: A Proven Principle

STUVEX, a recognized specialist in industrial explosion protection, offers the Flash Suppression System and Chemical Barrier solutions, specifically adapted to the constraints of the sugar industry.

The principle is simple and extremely effective:

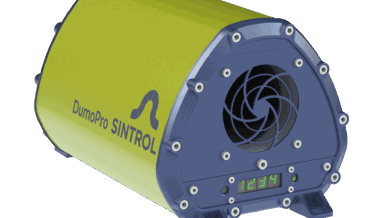

- Ultra-fast detection: pressure and/or flame detectors identify the very first signs of an explosion.

- Reaction within milliseconds: the system instantly triggers gas generators.

- Creation of a chemical barrier: a suppressant agent is discharged into the equipment (elevator, duct, silo), stopping the flame and preventing explosion propagation.

This ultra-fast response enables the explosion to be suppressed before it fully develops, thereby protecting the installation, personnel, and surrounding equipment.

5. A Solution Perfectly Suited to Existing Sugar Plants

One of the major advantages of the STUVEX Flash Suppression System and Chemical Barrier system lies in its ability to be easily integrated into existing installations, without heavy modifications to the process.

The installation examples show equipment protected directly on site, with compact and robust systems compatible with the hygiene and maintenance requirements of the agri-food sector.

In Europe, several sugar plants and storage silos belonging to major industrial groups are already equipped with STUVEX systems, demonstrating the maturity and reliability of the solution.

6. A Controlled Investment for Long-Term Safety

Installing an explosion suppression system represents an investment, but one that remains far lower than the potential costs of an accident (production shutdown, rebuilding, injuries, reputational damage).

Annual maintenance is limited and planned, including simple operations (functional testing, detector cleaning), ensuring maximum system availability over the long term.

7. Securing Today to Produce Safely Tomorrow

With increasing regulatory requirements and the need to secure industrial facilities sustainably, protection against dust explosions is no longer optional for sugar plants.

The STUVEX Flash Suppression system and Chemical Barrier solution provides a concrete, proven, and field-adapted answer. It enables sugar producers to protect critical installations, ensure operator safety, and maintain production continuity, while supporting a long-term risk management strategy.