The LAMBDA powder dosing system is a unique, programmable pump designed for the accurate and continuous addition of free-flowing solid substances such as powders, crystalline materials, and other fine or granular solids – across a wide range of scientific and industrial applications.

Working Principle:

Traditional screw feeders (augers) use a rotating helical blade to push powder through a tube. While widely used, this method can cause powder compaction, clogging, and mechanical stress – especially problematic for hygroscopic, fragile, or adhesive substances.

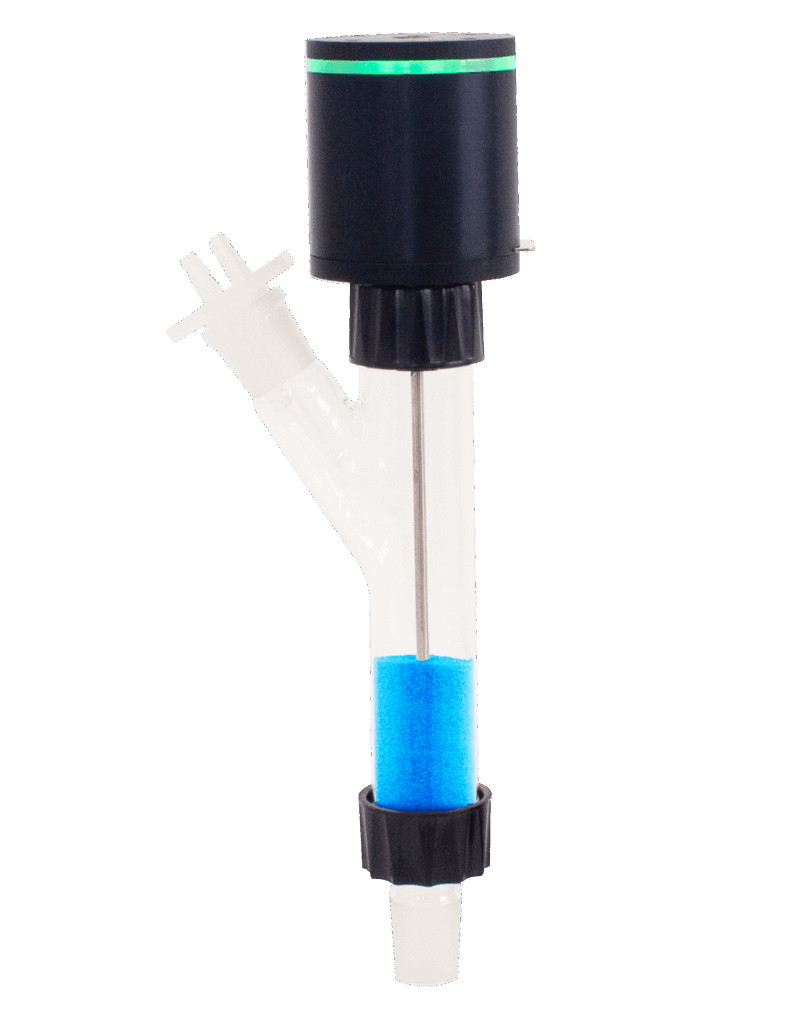

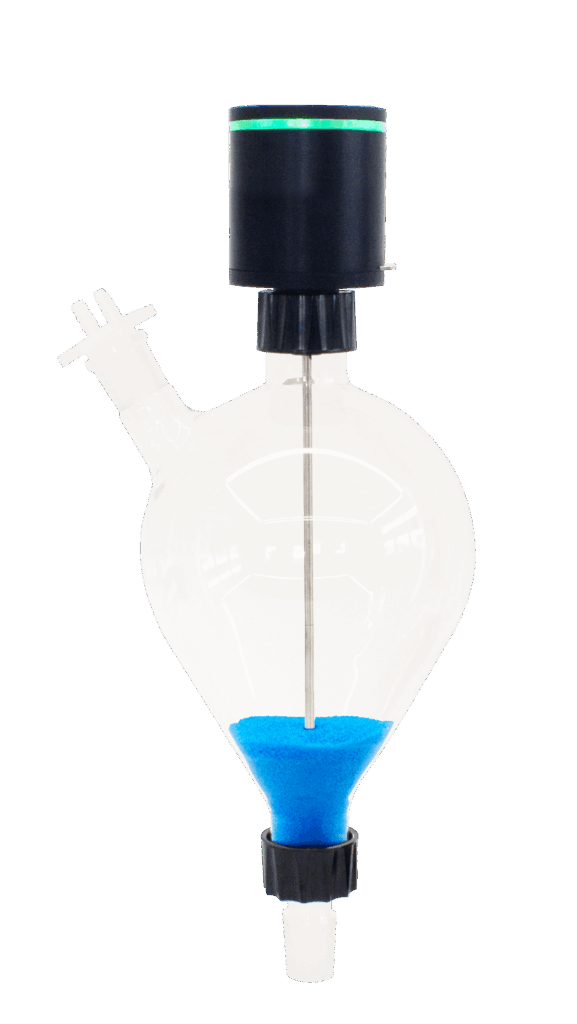

The LAMBDA DOSER touch uses a completely different approach – an open spiral-type powder distributor. Driven by quartz-precision motor control, the spiral gently conveys the powder into the outlet, allowing a clog-free, consistent volumetric dosing even with delicate substances.

Available vessel volumes: The DOSER touch models are available with the following standard glass vessel sizes: 0.2 L, 1 L, 3 L and 6 L. Optional coated vessels help prevent breakage and contain glass shards, offering added protection in cleanroom, GMP, and industrial environments.

For continuous operation with larger volumes, the glass vessels are equipped with a side neck that allows refilling during dosing, without interrupting the process.

Performance Specifications:

- Dosing range: 10 mg/min to 250 g/min (e.g. NaCl under lab conditions)

- Maximum powder particle size: approx. 4 mm

- Continuous operation with refillable vessels

- Touchscreen interface and remote-control options (analog, digital, foot-switch, etc.)

Versatile Applications:

Thanks to its compact design, the powder dosing unit can be installed directly inside:

- Laminar flow hoods

- Cleanrooms

- HEPA-filtered environments

It can also be mounted to chemical reactors, fermenters, or bioreactors and industrial-type machinery, enabling controlled, automated powder addition directly into the process vessel.

Enhanced Safety and Compliance:

LAMBDA DOSER touch powder dosing instruments are engineered to meet modern laboratory and industrial safety standards. They offer safe and reproducible dosing of hazardous chemicals, reducing exposure risks for researchers, technicians, and students.

- The hermetically sealed construction ensures secure handling of toxic or reactive powders.

- The device can be operated remotely, keeping personnel at a safe distance.

- Multiple sealing points make the system airtight, allowing safe use under slight overpressure or vacuum conditions.

- A gassing plug can be used to purge the vessel with inert or dry gas, protecting reactive or moisture-sensitive (hygroscopic) powders from clumping or degradation.

- For enhanced protection, glass vessels with an outer coating are available to reduce the risk of breakage.

- All materials in contact with powders are chemically resistant, ensuring long-term reliability even with aggressive substances.

Whether in scale-up or production environments, the LAMBDA DOSER touch sets a new benchmark in automated powder dosing – combining precision, versatile functionality, and advanced safety features in one compact instrument.

Contact us for application-specific guidance or support:

sales@lambda-instruments.com

www.lambda-instruments.com