Vital Products GmbH was looking for a precise and efficient solution to check the weight and ensure the completeness of its products. The main objective was to ensure the company’s high quality standards through reliable technologies. The production includes food supplements in the form of tablets and capsules, which are mainly filled in plastic bottles.

Process monitoring through weight control and software integration

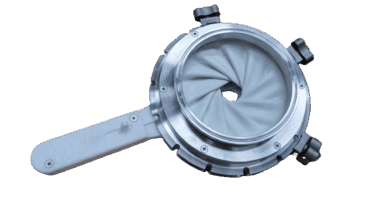

Minebea Intec supplied the Flexus® WS 1kg checkweigher including the powerful SPC@Enterprise software solution. This combination not only enables precise weight control, but also comprehensive process monitoring and analysis. The Flexus® checkweigher checks the weight of the plastic bottles highly accurately to ensure that each product meets the defined specifications. At the same time, the check scale performs a completeness check to ensure that all containers are filled correctly. The seamless integration of the SPC@Enterprise software allows Vital Products to evaluate the required production data in detail, identify weak points and optimise processes.

Successful use leads to expansion of the solution

The advantages for Vital Products are obvious: Quality assurance and greater efficiency with simple operation and seamless integration of the software into the production process . Thanks to the detailed data analysis, quality standards can be easily met and audits facilitated. This strengthens internal process reliability and end customers confidence in the Products of Vital Products.

Vital Products were extremely satisfied with the solution supplied and particularly emphasised the reliability of the Checkweighers and the quality of the Minebea Intec Service and Support team. This positive experience led to a further enquiry: two additional Checkweighers are to be added to the production lines to ensure that the entire production is equipped with Minebea Intec’s technology.

Customised solution as the basis for a long-term partnership

The project impressively demonstrates how Minebea Intec creates added value through innovative solutions and customer-orientated service. The combination of precision, efficiency and process control has not only improved production quality at Vital Products, but has also laid the foundation for a long-term partnership. Vital Products is an excellent example of how customised solutions from Minebea Intec can help to meet demanding customer requirements and at the same time secure a competitive advantage.

“The solutions of Minebea Intec, especially the Flexus® checkweigher, have significantly improved our product quality and processes. Precision, reliability and excellent Service are convincing across the board.” – Rainer Skotnik, Managing Director at Vital Products GmbH.

Key facts

Vital Products GmbH needed a reliable solution to check the weight and completeness of its Products precisely and efficiently. The plant produces nutritional supplements such as tablets and capsules, which are mainly filled into plastic bottles.

Application

The Flexus® checkweigher checks the weight and completeness of plastic bottles. Vital Products uses the SPC@Enterprise software to analyse production data, identify weak points and optimise its processes.

Products

- Checkweighers Flexus®

- Software SPC@Enterprise

Customer benefits

- Precise weight control and completeness checks ensure compliance with strict quality standards.

- Detailed data evaluations enable production processes to be optimised and increase process reliability.

- Seamless software connection facilitates quality control and supports audits.

Customer

Vital Products GmbH is a leading contract manufacturer of food supplements based in Waldsassen, Germany. Since 2002, the company has been offering comprehensive services from product development to packaging . With modern production facilities and the highest quality standards (DIN EN ISO 9001, IFS Food), Vital Products supplies capsules, tablets and powder blends “Made in Germany” worldwide.