The seminar shone a spotlight on cutting-edge advancements in powder handling technology crucial for the battery manufacturing industry. A highlight was a special session by the Swiss Dec Group, renowned globally for its expertise in powder handling and containment solutions. The group’s founder personally visited Korea to showcase the latest innovations in this field.

During the session, emphasis was placed on the growing importance of safe and efficient powder processing as the battery industry expands rapidly. Industry professionals were particularly engaged with demonstrations of the closed Powder Transfer System PTS, which was showcased through realistic manufacturing process simulations. Attendees responded enthusiastically, recognizing the significance of these solutions in enhancing safety, productivity, and product quality.

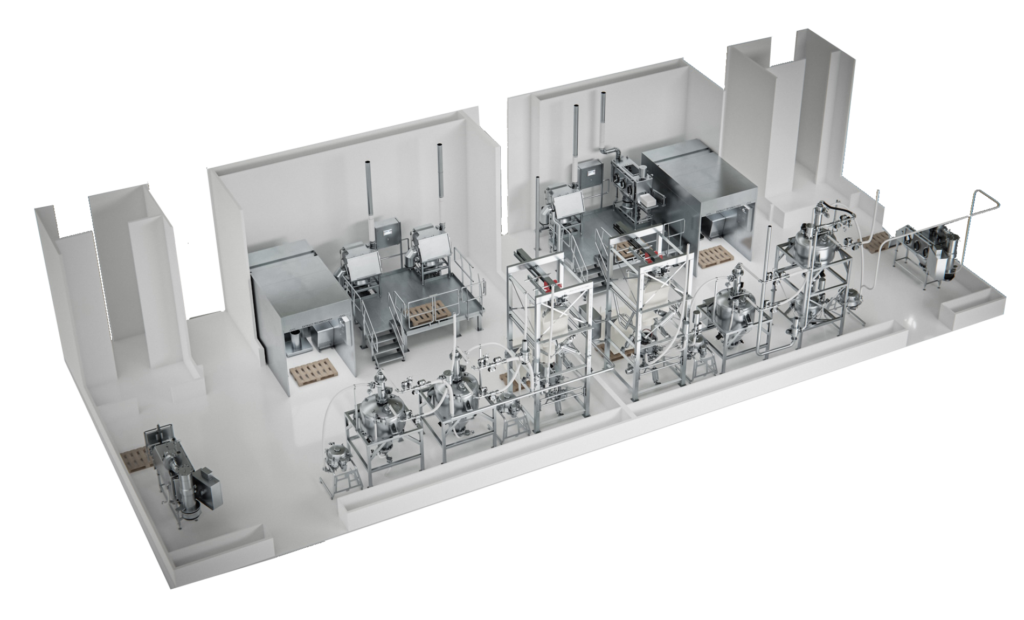

The seminar underscored that precise powder handling and advanced chemical equipment are pivotal in producing high-quality batteries. Key technological solutions introduced included high-containment systems to prevent dust exposure and cross-contamination, optimized conveying and dosing devices to resolve transport issues, and specialized mixing and grinding equipment designed to minimize particle damage and equipment wear. Additionally, equipment capable of blocking moisture and air exposure was highlighted as essential for maintaining material integrity, thereby boosting safety and efficiency.

A comprehensive approach was advocated to streamline process connectivity, minimize manufacturing space, and maximize productivity. These innovations not only enhance operational efficiency but also contribute significantly to worker safety and environmental protection.

Industry experts recognized that even small particles’ movement impacts overall product quality, making precision in powder handling indispensable. Addressing challenges such as dust diffusion, moisture absorption, and raw material clogging is vital to prevent productivity setbacks and ensure consistent yields.

The introduction of advanced technologies – closed conveying devices, modular mixing systems, and high-precision weighing and packing solutions – has garnered positive feedback from the field. These innovations are set to elevate the competitiveness of powder processes within battery manufacturing, marking a significant step forward in balancing safety, quality, and efficiency.