Known for its robust engineering capabilities and turnkey services, 4B was selected to design, supply, and install a solution that would meet the manufacturer’s current and future hazard monitoring needs.

Challenge

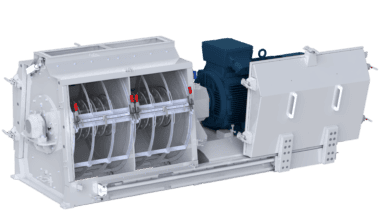

The pet food facility had previously installed a network of hazard sensors to monitor belt misalignment, speed, and component temperature. However, over time, these sensors had either failed or been disconnected, leaving the system ineffective. In some cases, visible wear was evident – such as a belt wearing through a sensor face – indicating a critical loss of hazard detection.

This lack of monitoring posed a risk not only to equipment integrity but also to plant safety and operational uptime. Complicating the matter, the manufacturer wanted to retain their existing PLC setup. This required a new system that could collect data from multiple sensors and feed it directly to the PLC via a reliable communication protocol.

Furthermore, the upgrade needed to be completed with minimal disruption to production and with scalability in mind, ensuring future enhancements could be added without overhauling the entire system.

The Solution

After a detailed site assessment, 4B engineers recommended the deployment of the IE-Node hazard monitoring system – a modular, Ethernet/IP-ready platform that connects a full suite of hazard sensors to a facility’s existing control system.

Each IE-Node was installed to interface directly with a group of sensors assigned to an individual bucket elevator. These included:

– Belt speed sensors

– Belt alignment sensors

– ADB series sensors to monitor bearing, motor, and gearbox temperature

– Blocked chute detectors (Binswitch)

To support structured cabling and reduce installation complexity, each bucket elevator was fitted with junction boxes at both the head and tail sections, along with a central junction box for consolidating signal and power wiring.

The IE-Node’s compact, panel-mountable design made it easy to incorporate into the existing equipment layout. Its compatibility with Ethernet/IP ensured seamless data transfer to the plant’s PLC system, without the need for additional interface converters or complex programming.

In addition to equipment supply, 4B provided full installation and commissioning services. Their specialist engineers handled the complete setup, including sensor mounting, cabling, configuration of the IE-Nodes, integration with the PLC, and final on-site validation. The entire system was commissioned within a predefined timeframe, ensuring smooth transition and minimal disruption to ongoing operations.

Results

The upgraded hazard monitoring system has restored and significantly improved safety and operational efficiency at the plant. With real-time hazard detection reinstated on all 16 bucket elevators, the manufacturer now benefits from:

– Comprehensive monitoring of critical hazard points

– Reliable data transfer to the PLC via Ethernet/IP

– Improved equipment reliability through early warning of mechanical issues

– Streamlined maintenance and diagnostics enabled by centralized data visibility

– Future scalability, thanks to the modular architecture of the IE-Node system

This project showcases how 4B’s integrated approach – combining engineering expertise, advanced monitoring hardware, and hands-on installation – can transform ageing or disconnected safety systems into fully modernised, connected infrastructures.

A project engineer from the plant summarised the experience:

“Working with 4B on this project from start to finish has gone very well! From the initial conception with prompt site visits and regular communication, to installation and commission, nothing was too much trouble for 4B. James’ in-depth knowledge of the systems has allowed for a swift handover period to the factory and we can now monitor and track the ATEX risks efficiently and precisely on our priority areas in the factory! Thank you James and 4B!”