The facility features underground tunnels equipped with conveyor belts to move grain between processing stages. These tunnels are rarely entered by personnel, which creates a challenge: significant dust accumulation can go unnoticed until it reaches dangerous levels. This concern became even more pressing following a 2023 incident at a similar plant in southern Brazil, where a tunnel dust explosion resulted in ten fatalities.

Real-Time Monitoring in Action

To mitigate this risk, the plant implemented a real-time dust concentration monitoring system, integrated into its PLC-based process control. The system was supplied through Grunn do Brasil, the local representative of Sintrol, a Finnish technology company specialized in industrial dust monitoring and emission measurement solutions.

Shortly after installation, the system began recording an unusual rise in dust levels in one of the tunnels. Maintenance personnel investigated and discovered a mechanical failure: a grain spout seal had ruptured, releasing dust into the tunnel over an extended period. Although no ignition occurred, the accumulated material posed a serious explosion hazard under the right conditions.

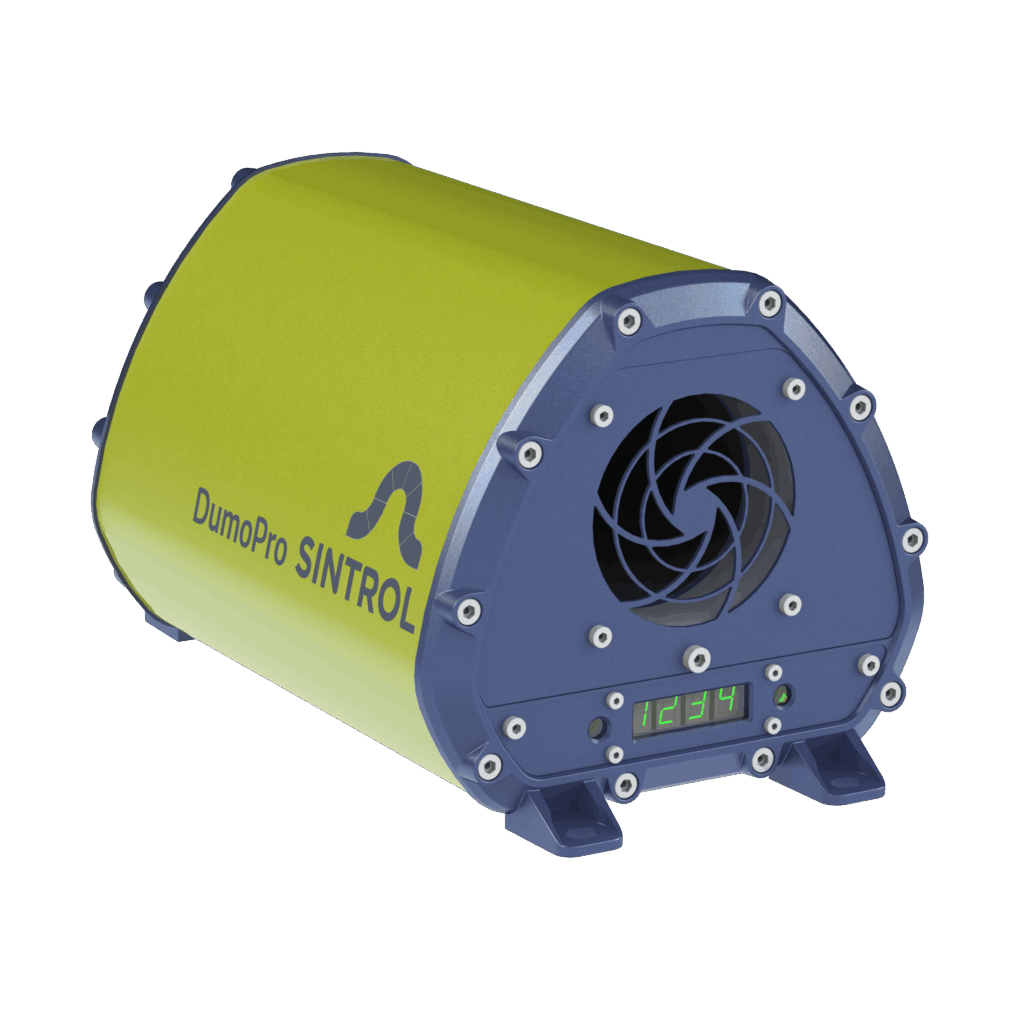

The monitoring system used in this case was Sintrol’s DumoPro, designed specifically for continuous dust measurement in demanding industrial environments.

Importantly, the facility used the PLC-linked monitoring data to inform access decisions: personnel were only allowed into the tunnel once dust concentrations had dropped to safe levels, as indicated by the system. This approach protected both human health and process safety, demonstrating how a single investment can address multiple critical risks.

Results and Implications

Thanks to the early warning, the facility was able to act promptly—repairing the source of the dust and removing the buildup before the situation became critical. Data gathered from the monitoring system also informed changes in inspection routines and maintenance planning, particularly for areas not routinely accessed by staff.

Conclusion

This case underscores the value of real-time dust monitoring as part of an overall safety and risk management strategy in bulk material handling. Systems like DumoPro, when integrated with plant automation, allow operators to detect hidden hazards and respond before they escalate—while also enabling data-informed decisions that safeguard personnel.

About Sintrol

Founded in Finland, Sintrol develops and supplies particulate monitoring systems for industrial process safety, environmental compliance, and explosion risk prevention. Its solutions are used globally in industries such as power generation, grain handling, cement, and metal production.