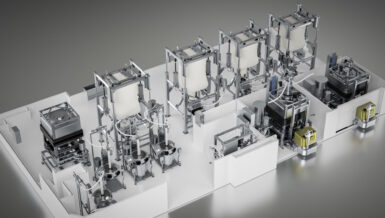

A weighing scale was installed beneath each feeder to provide continuous feedback on the weight of the dosed ingredients. This feedback allows the system to make real-time adjustments, ensuring optimal dosing accuracy. The control box, also designed and delivered by HETHON, manages the entire process and controls each individual feeder. As a result, fully automated and error-free dosing is achieved.

Global Reliability and Applicability

HETHON has been a trusted name in dosing technology for decades, with a strong reputation in the food industry. In the Netherlands, virtually all major peanut butter producers rely on HETHON systems to precisely dose their ingredients — including sugars, salts, flavors, and other powdered or granular additives. Thanks to their reliable performance and modular design, HETHON Feeders are also a popular choice worldwide.

The project in India is an excellent example of HETHON’s international ambitions. By carefully listening to the specific needs of the customer and translating them into tailor-made solutions, HETHON proves that its technologies are widely applicable — regardless of location or product.

Smart Technology and Remote Support

One of the most innovative aspects of this project is the integration of Wi-Fi connectivity. This feature enables operators to control all feeders easily via a tablet or smartphone. They gain real-time insight into the process, can adjust settings, and detect or resolve malfunctions without being physically present at the installation.

Moreover, the internet connection allows HETHON’s service team to remotely log in and immediately identify and resolve any issues. This saves time and costs, minimizes downtime, and boosts the overall productivity of the factory.

Benefits for the Customer

The customer benefits from multiple advantages:

- Accurate dosing: Less waste, consistent product quality

- Efficiency: Faster production through automation and carousel layout

- Flexibility: Easy adjustment of settings for different recipes

- Ease of maintenance: Many issues can be quickly resolved with remote support

- Scalability: The system can be easily expanded to meet growing production demands

Conclusion

With this delivery, HETHON once again demonstrates its expertise in providing customized solutions for complex production environments. Whether it’s a factory in the Netherlands or in India – HETHON guarantees precision, reliability, and innovation. The collaboration with the Indian customer highlights that HETHON’s technology is trusted around the world and truly contributes to the quality and efficiency of food production.