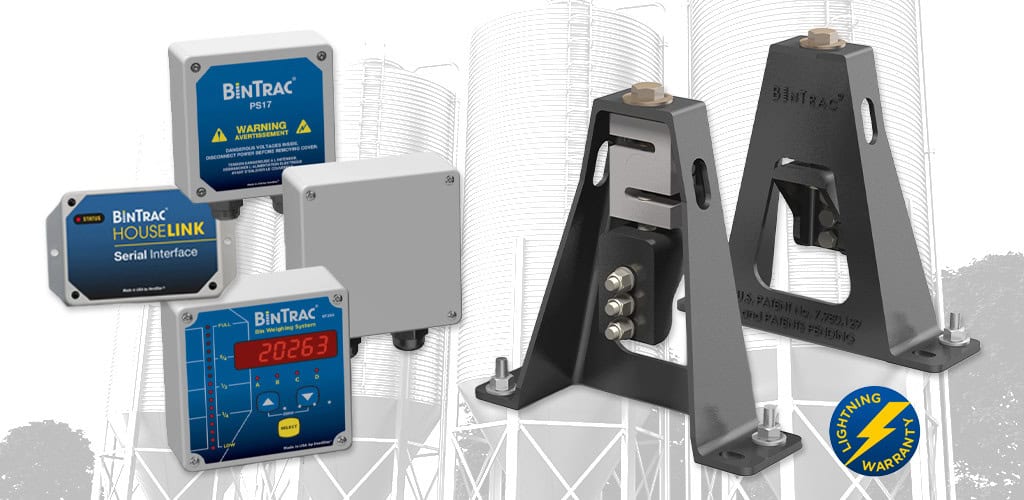

Enter BinTrac®: a bin weighing, inventory and batching control system designed to deliver reliable, real-time data on bin contents, usage, and fill events. Originally developed for agricultural feed operations, BinTrac also serves as a versatile solution for industrial markets including plastics, bulk commodities, and microbreweries/distilleries.

The Industrial Need: Why Batching + Weighing Matters

1. Real-Time Visibility & Inventory Control

A persistent challenge in bulk solids handling is “blind inventory.” Bins may seem full, but workers truly don’t know unless they climb up and poke around. Bridging, tunneling, and uneven piling can lead to inaccurate measurements when relying on a level measurement sensor versus a weighing device.

With BinTrac weighing systems, current inventory is displayed at the bin, and historical fill/usage data is stored. Detect trends, such as unusually fast drawdown, and schedule replenishment proactively.

2. Integration with Automation & SCADA

Industrial plants often already have a supervisory control layer (SCADA, PLCs, MES). BinTrac offers interfaces (HouseLINK™) to transmit bin-scale data into third-party control systems, ensuring seamless integration of inventory and batch control into existing architecture.

3. Remote Monitoring & Data Access

For multi-location operations or remote plants, BinTrac’s remote data collection and BinTrac Vision web monitoring enable access to bin-level data from a browser, tablet, or phone. Review usage, fill events, alerts, and historical trends from anywhere.

4. Safe, Cost-Effective Retrofit Installation

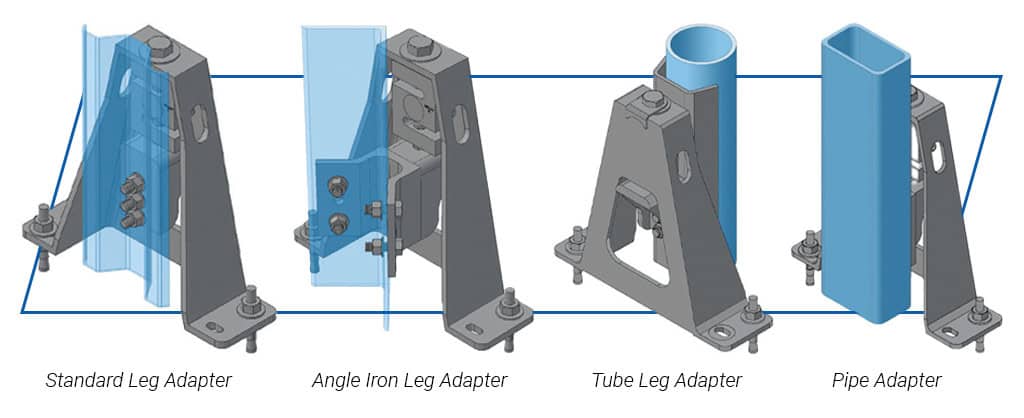

One compelling advantage of BinTrac is its patented bracket and adapter systems that allow load cells to be mounted on existing bin leg structures—often even when bins are loaded—without dismantling. This greatly reduces downtime and installation costs.

How BinTrac Works: Architecture & Key Components

1. Bin Weighing Module / Load Cells

The core of BinTrac. This setup integrates with a bin’s structural support to continuously sense changes in weight. The module stores and displays the bin’s net weight, usage over the past 24 hours, and last fill events.

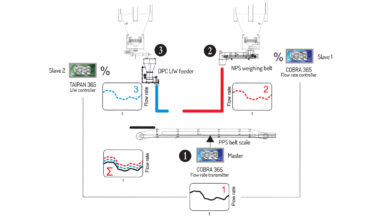

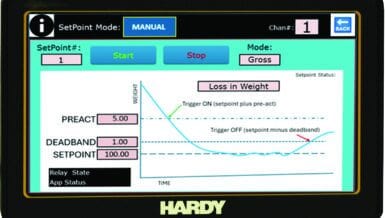

2. Batching Control / Indicator

The BinTrac Batching Control System (a BTB-200 or Dual BTB-200) acts as the “brains” for loading or unloading of material.

- Load Batching / Gain-in-Weight: Batches material into a weigh bin until the target gross weight is achieved.

- Unload / Loss-in-Weight batching: Releases a measured amount from a source bin until the target net weight has been unloaded. The same controller can schedule automatic batch events, enable/disable feed lines, and log batch history.

3. HouseLINK™ Interface

This optional hardware interface electrically isolates and transmits bin-scale data to existing control systems. Thus, workers can see real-time weight, usage, and batch commands without re-architecting an entire control setup.

4. Site Communications & Remote Data

BinTrac offers LoRa-based wireless communications or wired links to connect multiple bin modules and consoles across a site to a local communication hub. Radios transmit via line-of-sight, up to four miles.

From there, data is streamed to the secure database, where operators can access it anywhere, at anytime via BinTrac Vision.

5. Configuration Options & Scalable Topology

BinTrac supports modular topologies: single bins, multiple bins, dual/triple batching setups, or networked arrays.

For example, a triple batching configuration might control both the load into the weigh bin and two unload streams (dual unloading) out of the weigh bin.

6. Calibration & Stability

One key advantage is that the BinTrac load cell modules are pre-calibrated (temperature, linearity, zero), and typically require no field calibration, reducing maintenance or drift issues seen in other mechanical systems.

Industrial Use Cases & Benefits

Breweries & Distilleries

In brewing and distilling operations, raw materials like malt and byproducts such as spent grains are often held outdoors in bulk bins or hoppers. A BinTrac system provides:

- Verifying deliveries: Fill-event data is stored in the local display.

- Inventory tracking: Real-time data on remaining malt stocks helps plan logistics and avoid downtime from stockouts.

- Traceability: View the exact weight output of each batch event, as well as the dates and times of previous batches, on the system controller.

- Retrofitting flexibility: Many existing silo or hopper installations can be upgraded to BinTrac sensors without major downtime or civil construction.

Plastics Processors / Resin & Additive Handling

Plastic manufacturers typically handle raw resin pellets, colorants, additives, fillers, or powders stored in silos or day bins. Challenges include segregation, density shifts, and precise compounding. With BinTrac:

- Verifying deliveries: Fill-event data is stored in the local display.

- Accurate raw material metering: Ensure the correct amount of material is expended, helping processors maintain control over processes.

- Mass balance & loss control: Track how much material enters vs. product output to detect leakages, spills, or theft.

- Downtime reduction: Monitor inventory trends to preempt outages.

- BinTrac helps processors of plastics, pellets, and other bulk commodities in various types of injection molding or sheet film manufacturing applications.

Other Bulk Solids & Processors

For industries handling chemicals, minerals, food powders, pellet fuels, plastics recycling, or bulk commodities, BinTrac offers similar advantages: reduced manual inventory checks, improved accuracy, real-time level alerts, and audit trail of material flows.

Implementation Considerations & Best Practices

When evaluating or planning to deploy BinTrac systems, users should consider:

1. Bin & Structural Assessment

- Bin leg design & attachment geometry: Evaluate compatibility with existing leg structures.

- Load path isolation: Consider structural stiffness, thermal expansion, and vibration to avoid erroneous weight readings.

- Empty weight (zeroing): The system needs to subtract the empty bin (“tare”) weight correctly; this is set during initialization.

2. Choosing Batching Mode & Topology

- Decide whether your process needs load-batching (adding material) or unload-loss-batching (removing measured weight). BinTrac supports both.

- If you have multiple feeders or multiple output lines, dual or triple batching configurations may be appropriate.

3. Controls & Integration Strategy

- Establish how batch completion signals sync with downstream equipment such as conveyors, valves, or screw feeders.

- Use a HouseLINK device to create a communication interface between the BinTrac data scale and your control system.

- Plan for fail-safe behaviors—consider alerts and notifications if bins become empty.

4. Communications & Network Reliability

- Evaluate whether radio, wired, or hybrid communications best suit your site layout and interference environment.

- Ensure redundancy or convenience, like the use of local displays at groups of bins.

- Consider bandwidth needs if large-volume historical data or diagnostics will be transmitted or stored.

5. Environmental & Safety Considerations

- Install load cell electronics and instrumentation with consideration to moisture, dust, temperature extremes, or corrosive materials.

- Surge protection and lightning mitigation are standard and unique to BinTrac systems.

6. Validation & Commissioning

- Conduct acceptance tests comparing measured vs. known weights across the full fill/unload range.

- Capture data over several operational cycles to verify stability, linearity, and repeatability.

ROI & Business Value

Industrial users investing in BinTrac systems typically see returns in:

- Raw material savings: By reducing overfeed or underfeed across many batches.

- Reduced spoilage or off-spec production: Typically due to improper dosing.

- Labor savings: Fewer manual bin weighing checks, inventory rounds, or corrective rework.

- Better scheduling & procurement: Real-time visibility allows demand forecasting and just-in-time replenishment.

- Traceability / Audit readiness: Batch logs aid in quality assurance, regulatory compliance or certification efforts.

Over time, these benefits compound—especially in high-throughput plants or operations with many bulk material and ingredient bins.

Better Batching with BinTrac

BinTrac offers industrial processors a robust, scalable solution for precise batching and continuous bin inventory measurement.

By bridging the gap between blind-bin operations and real-time, batch-aware control, BinTrac enables tighter process control, cost optimization, and advanced integration into automation systems.