However, when accuracy is insufficient, operators face major obstacles: financial disparities, underutilized storage capacity, frequent downtime, and weak traceability.

Continuous level sensors, such as BinMaster’s compact non-contact radars and ultrasonic transmitters, deliver long-term, precise performance to ensure bulk material is properly accounted for in tanks, silos, and conveyors.

In addition, weight sensors like BinTrac® A-frame load cells simplify material tracking in outdoor bins, without the need for calibration or expensive installation.

Sensor systems that combine multiple approaches to material management enable smarter diagnostics and preventative redundance to ensure always-accurate, consistent measurements and reporting.

Common Measurement Challenges in Powders, Bulk Solids, and Liquids

Evaluating the characteristics of the material being measured, qualities of the storage vessel, and environmental conditions will help determine the best choice of sensor.

- Material Behavior: Will bridging, ratholing, or changes in dielectric constant be present?

- Environment: Will the sensor technology be challenged by dust, temperature changes, condensation, vibration, or turbulence?

- Process Constraints: Is it a new or retrofit installation? Is there limited headspace? Does the sensor need certifications or to meet hygienic requirements? Will it be exposed to outdoor elements?

BinMaster’s solutions include options to meet diverse inventory measurement needs. Where one technology may struggle, another sensor’s performance thrives.

Compact Non-Contact Radar (CNCR) Sensors

- Technology: Measures reflected radio waves, returning measurements as accurate as ±2 mm

- Strengths: Unaffected by dust, temperature, and vapors; provides a long measurement range; minimal maintenance requirements; suited for solids, powders, and liquids with varying bulk densities, specific gravities, or dielectric constants

- Typical Mounting: Simple installation, mounted at the top of a silo or bin; includes selection of swivel mounts and additional flanges or adapters

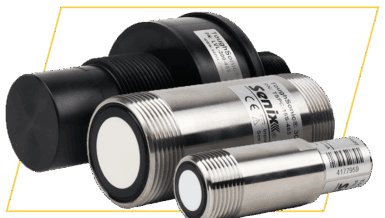

ToughSonic® Ultrasonic Sensors

- Technology: Emits high-frequency soundwaves—upon reflected waves’ return, the time in between emission and reception is translated to a distance measurement

- Strengths: Accurate at short-to-medium range (up to 50 ft.), non-intrusive and economical design; well-suited for liquids and slurries in mixers or blenders

- Limitations: Soundwaves can be scattered by dust, vapor, and extreme temperature changes, resulting in errors or mismeasurements

BinTrac A-Frame Load Cell Modules

- Technology: S-type or pancake-style load cells are used for consistent, accurate weight measurement; patented brackets simplify installation with integrated jack bolt for lifting; designed with robust protection against lightning strikes or surges; built-in compensation for temperature-related changes

- Strengths: Weight is independent of material type, moisture content, density, or surface irregularities; accurate loading/unloading processes

- Typical Mounting: A-Frame bracket is mounted on bin legs; suitable for retrofitting existing bins

Together or Separate? Level Sensing & Weighing Strategies

When operating independently, these sensors deliver dependable, actionable measurement data. But together, level and weight technology offer absolute inventory: while radars or laser transmitters detect high/low alarms and trends, load cells capture total weight.

This joint system also supports redundancy, giving operators the chance to cross-check inventory readings. This serves as an extra layer of protection against out-of-stock events or in the case of unplanned equipment downtime.

For example: in a livestock feeding operation, multi-sensor integration might include a laser or radar sensor collecting real-time level readings on silos containing animal feed, while bin scales on the farm provide inventory verification via weight.

Industry Applications

The need for hyper-accurate inventory is a given, especially in processing industries with fast-moving bulk materials and multiple production lines.

- Breweries: Batch unloading and loss prevention in grain hoppers; radar sensors measure through foam in fermentation tanks for precise measurements

- Plastics: Measure resin pellets in bulk storage vessels with sensors or scales

- Agronomy & Fertilizer: 80 GHz radar is superior in dusty storage vessels; level and weight sensors eliminate safety risks of workers climbing outdoor silos and indoor tanks; load cells weigh and unload batches with precision

- Milling & Grain Handling: Radar provides continuous level readings, while bin weighing adds accurate tonnage; for high- or low-level alerts, consider rotaries or diaphragm switches for point-level sensor integration

- Food Processing: Non-contact sensors are preferred for sanitary lines, whereas load cells offer inventory in outdoor tanks containing raw ingredients; utilize ultrasonics or small radars—depending on headroom—to measure levels of tanks or hoppers

- Conveyors & Feeders: Monitor the height of conveyed materials, prevent overflows, or control feed rate onto conveyors; utilize ultrasonics for object detection or material height

Integration with Process Control & Software

Inventory control is simplified by sensors that are compatible with cloud-based systems.

For example, BinCloud® software provides bin- or site-level monitoring, along with advanced analytics that enable users to anticipate trends, mitigate future waste, and proactively place orders. Measurement data from both BinMaster sensors and BinTrac weighing systems integrate into BinCloud to form comprehensive, real-time reports.

With this information, operators can automate loading/unloading processes or program sensors to open or close gates and pumps, based on pre-configured high or low levels within the storage vessel.

Local integration simplifies monitoring for workers on the ground. By connecting sensors to a SCADA system and/or PLCs, workers can set process control commands, allowing the technology to do the heavy lifting on their behalf.

Joint Impact of Level & Weight Sensors

Radar, ultrasonic, and weight sensors offer strengths that complement existing in-house controls, as well as one another. By combining these means of measurement, industrial and agricultural producers receive robust insights into accurate inventory they can rely upon.

After evaluating initial considerations, such as application requirements and storage vessel constraints, contact an expert at BinMaster to begin assembling your plant’s personalized measurement system.