Both sensors are rugged, dependable, and easy to install, making them ideal for a wide variety of industries and applications. Whether used for process protection or inventory management, they play a vital role in monitoring bins, hoppers, silos, and tanks.

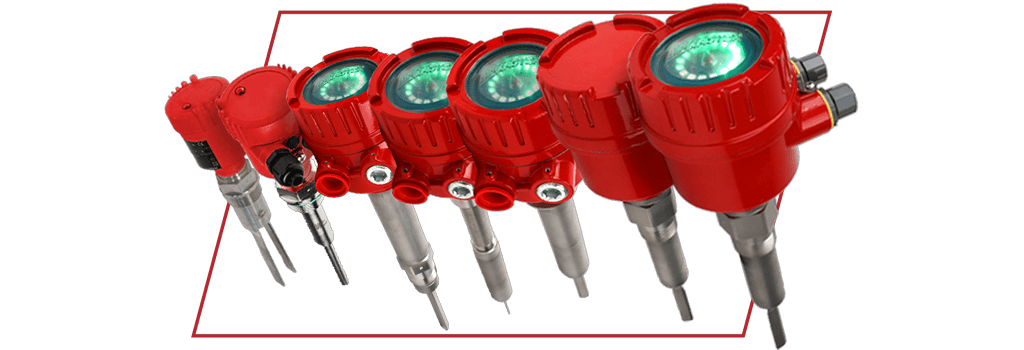

VRX Vibrating Probes: Sensitive & Durable

BinMaster’s VRX vibrating probes are designed to detect the presence or absence of material at a specific point in a container. They operate using a buildup-resistant, blade-shaped sensor that vibrates at a frequency. When covered by material, the vibration stops—triggering an alert.

Key Benefits of VRX Probes:

- Works in low-dielectric materials like plastic powders, silica, or starch

- Self-cleaning design prevents material buildup on the probe

- No calibration required—easy to install and operate

- Adjustable sensitivity for fine, powdered, or very light bulk solids

- Compact models are available for tight spaces or small vessels

- High-temperature models for demanding process environments

The VRX is commonly used for high- or low-level detection in hoppers, to start or stop processes, control conveyors or augers, or send alerts to operators. It is an excellent choice when dealing with powdery, dry, or aerated materials that may be difficult for other technologies to detect reliably.

BMRX Rotary Level Indicators: Tough and Time-Tested

BinMaster BMRX rotary paddle indicators are a workhorse of the process control industry. When installed at a desired point, the paddle rotates freely until it is impeded by material—signaling that the level has reached that point.

Why Choose the BMRX Rotary?

- Simple mechanical operation—no need for complicated electronics

- Reliable in challenging materials like sand, grains, pellets, or feed

- De-energizing motor extends motor life when material is present

- Fail-safe features on BMRX-300 indicate power failure or mechanical fault

- Multiple paddle styles to match bulk density and flow characteristics

The BMRX is particularly useful in detecting material presence at start/stop points in silos and hoppers, helping operators avoid overfills, outages, or equipment damage.

Industries That Depend on BinMaster Level Sensors

These level sensors are widely used in facilities that process or store dry powders, pellets, granules, and other bulk solids. Some of the common industries include:

- Grain storage and handling

- Feed mills and ingredient blending

- Monitoring levels in corn, soy, wheat, and DDGS

- Level control in silos for cement, fly ash, and lime

- Managing materials like gravel, sand, and crushed stone

- Monitoring flour, sugar, and powdered ingredients

- Use in bakeries, snack food processing, and dry goods production

- Resin pellet storage and plastic powder bins

- Ensures consistent supply for molding or extrusion processes

Chemicals:

- Powders like carbon black, talc, or detergents

- Process control in mixing, blending, and reaction vessels

- Helps prevent clogs and maintain consistent fuel feed

- Coal, fly ash, and biomass material handling

Instrumentation & Process Control

Both the VRX and BMRX point-level sensors are more than just switches—they’re vital tools for automated process control. Using a relay connected to a plant’s system, they provide high- and low-level alert notifications to monitor levels and automate responses.

Common Uses in Automation:

- Start/stop conveyors or augers when material is detected

- Activate alarms or lights when bins are empty or full

- Protect pumps and mixers from running dry

- Enable batching systems to verify material presence before operation

- Prevent overfilling of transport or storage vessels

By integrating these sensors into a facility’s automation systems, companies benefit from greater efficiency, reduced downtime, and enhanced worker safety.

Choosing the Right Sensor

Both the VRX and BMRX level sensors are excellent solutions, but the right choice depends on the material and environment:

Choose VRX vibrating probes when:

- Managing low-dielectric materials

- Detecting very light powders or fine particles

- Hygienic or dust-sensitive conditions are a concern

- A compact or vertical mount is needed

- You want no moving parts and minimal maintenance

Choose BMRX rotary level indicators when:

- You need a robust, mechanical solution

- The material has medium to high bulk density

- You want a cost-effective and time-tested sensor

- The process includes granular or pelletized materials

Proven Performance

BinMaster’s VRX and BMRX sensors are trusted across many industries for their simplicity, reliability, and accuracy in level detection. Whether used in powders or bulk solids, they offer peace of mind and process control in even the most demanding environments.

For any plant or operation dealing with material management, these sensors are an essential part of your level instrumentation toolbox.

Ready to optimize your process? Talk to a BinMaster specialist today to choose the best level sensor for your material and application.