As a mechanical conveying technology, tubular chain conveyors have been meeting people’s needs for high quality, medium volume conveying for over 50 years. First developed and applied in Europe, the tubular chain technology is considered simple to operate and maintain. Its compact design doesn’t require supporting ancillary equipment and is highly energy efficient. Tubular chain conveyors are flexible in design and customization, clean in operation, and safe in application. They are used to transfer a variety of conventional products which can include toxic, volatile, and hot materials.

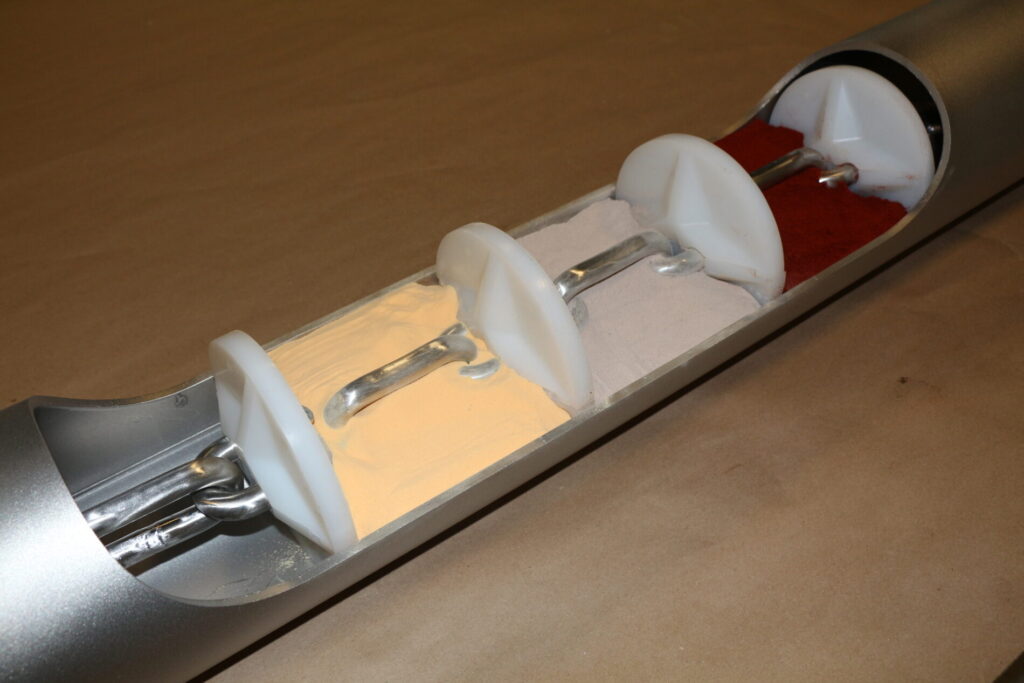

Tubular chain conveyors transfer powder, pellet, granular, and volatile materials gently between discs fixed to a moving chain within an enclosed and sealed conveying pipe.

The ability to retain all product within the conveyor from the point of inlet to the outlet prevents materials from spilling, dropping and floating up into the workspace. The sealed design of this mechanical conveying technology also makes it ideal for equipment that are washed down as part of the operational protocol.

For the food, chemical, industrial, and ingredients industries, the tubular chain conveyor technology will keep workplaces clean and safe for operators.

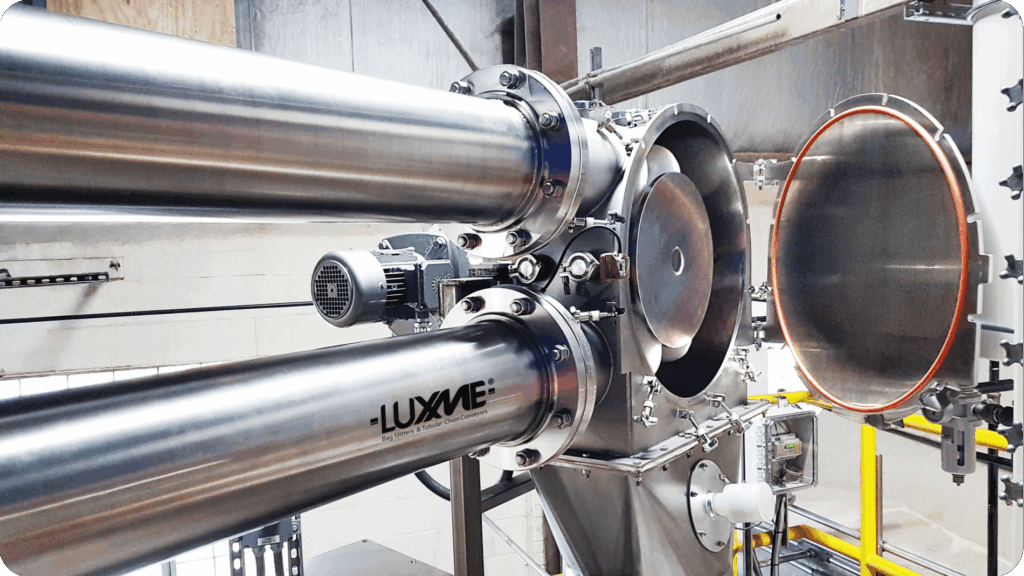

These conveyors are available in 4, 5, 6, 8 and 10-inch diameters. They deliver up to 2,100 cubic feet per hour. Designed for full start and stop conditions, they transfer product at a constant rate based on chain speed. Conveyors are set up with constant torque, variable speed drives to provide operators with an adjustable speed transfer that can be associated with material transfers that require ramp-up or ramp-down transfer rates. This is particularly applicable to delivering product as ingredients to set weights or volumes in making up a multi-ingredient batch for mixing or blending.

The conveyors can be constructed of carbon steel, stainless steel 304, and stainless steel 316L to provide users with the right product contact materials that are compatible with the products to be transferred. Transfers can be set up with multiple inlets, and outlets. Tubular chain conveyors operate at atmospheric pressure that avoids releasing product fines to the atmosphere which can generate airborne dust. Keeping dust from contaminating a workspace will reduce the risk of explosion when handling materials that are explosion risks if left to build up to ignition point concentrations.

Tubular chain conveyors are available in design types that meet the needs for industrial, food and sanitary transfers. Each conveyor can be adapted to the hygiene standards and layouts of most transfers.

To support a wide variety of application across many industries, tubular chain conveyors are supplied in multiple design categories that include:

- Standard Industrial – Conventional high-quality construction with high reliability and equipment longevity that target a 15 to 20 year service life.

- Stay-Clean – Used to handle a variety of sticky products while ensuring materials are not retained within the conveyor. Allows the conveyors to run cleaner, longer and reduce downtime related to clean out and washdown.

- Food Safe – Designed to FDA standards and operate with self-wiping, self-purging capabilities that are matched to the food product, and food industry.

- Sanitary – Ideal for handling ‘Ready-to Eat’ foods to packaging or where frequent sanitary washdowns are required.

Each of these tubular chain conveyor groups will adopt components to improve the transfer efficiency of the conveyor. Wipers, scrapers, brushes, vibrators and air knives can be integrated in the design to ensure all material fed into the conveyor is delivered to the desired outlet. Conveying parameters such as carry-over, cross-contamination, product degradation, internal build-up and plugging can all be avoided with the proper set-up and design of a tubular chain conveyor.

Because this is a mechanical conveying technology, throughput variability from bulk density variation, particle size variation, and infeed variability is avoided. Tubular chain conveyors will deliver material at a consistent rate with little influence on particle size distribution.

Conveyor operating or product transfer speeds range from 10 FPM to 90 FPM to maintain high product quality through the transfer. Keeping transfers below 100 FPM while avoiding an excess number of sharp elbows will avoid product breakage, fines generation, carry-over, heat generation, noise, and premature wear of conveyor components. These systems are typically designed to a 15-to-20-year service life. They adopt case-hardened chain design and sprockets made from forgings to extend service life in very demanding, sometimes very abrasive, operating conditions. Discs are offered in a variety of designs and materials to optimize yield, product integrity, wear rates and low operating noise.

As illustrated below, this mechanical conveying technology is versatile in its application. It is configured, sized and designed to support multiple, dust free transfer applications across all industries.

With over 45 years of tubular chain conveyor expertise, established tubular chain manufacturers offer cost effective designs. They offer custom solutions where durability, efficiency, cleanliness, and safe conveying are the priority.