These factors can include your:

- Product

- Belt Width

- Duty / Belt Speed

- Budge

Rollers alone with spacious gaps, do not give ample support to the critical transfer point. If support is not provided adequately, belt sag can occur – along with detrimental productivity issues such as material spillage and excessive dust. The product loss, equipment damage and downtime issues caused by poor conveyor belt support is inconvenient, unsafe and expensive.

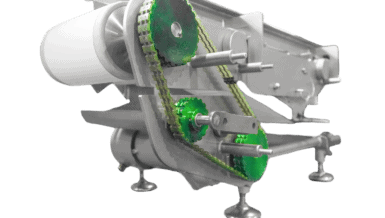

Kinder Australia’s K-Sure® Belt Support System is engineered to provide the heavy-duty support that your transfer point requires. It utilizes the existing conveyor idler frames and load, carrying the centre conveyor roller. The wing rollers are then replaced by the K-Sure® Belt Support System’s universal adaptor brackets and low friction polymer belt support rails.

K-Sure® Universal Adaptor Innovation

To ensure a precise fit, a specialized universal adaptor stud has been engineered by Kinder Australia. This allows for adjustment to suit three different size roller diameters, offset/inline frames, and manufacturing tolerances in trough frames. Since its introduction, this innovative technology has transformed the industry benchmark, in delivering greater flexibility in conveyor transfer point configuration.

The K-Sure® Belt Support System requires no pre-engineering, adjustments or special tools. It is available in a standard 2 metre length assembly kit. Other lengths can be modified upon request. Effectively, it is designed to provide a consistent and stable support for the troughed belt profile by reducing the number of rotating components. K-Sure® Belt Support System eliminates any belt edge sag and therefore increases the effectiveness of the skirting seal.