However, one leading conveyor belt manufacturer, Netherlands-based Fenner Dunlop Conveyor Belting EMEA, see things differently and are successfully pioneering a radical change of thinking. In the past, single and dual-ply belts were used for only lighter applications but thanks to advances in technology, convention has been turned on its head.

A single and dual-ply future

Since they first introduced their hugely successful single and dual-ply UsFlex belt more than two decades ago, Fenner Dunlop have continued to develop the concept. Known as the X Series, they not only replace thick, multi-layered belts, they also provide numerous advantages. Although thinner and lighter, they are much more robust and resistant to damage than their multiple ply counterparts.

In theory, a higher number of inner plies should result in a stronger belt. However, the greatest influence on the strength and other essential physical properties of a conveyor belt is the design and quality of the ply material used to create the carcass. This is where Fenner Dunlop have a huge advantage over would-be competitors and imitators because they have their own fabric weaving facility in the USA.

It is here that they have developed a range of unique super-strength fabrics for single-ply belts (Ultra X and Nova X) and their longer established single and dual-ply UsFlex constructions. The carcasses possess a longitudinal rip resistance that is more than 500% greater than multi-ply belts of equivalent rating and up to 300% greater impact resistance compared to conventional belting. So, how does it all work?

The heart of the matter

The whole working principle of being able to create advantages from using single and dual-ply belts centres on the fabric. The priority has been to ensure that the individual fibres and yarns were of the highest possible quality and strength. Next comes the weave pattern.

The X Series has three versions of fabric. Ultra X features a specially woven “Crimped warp” carcass, combining crimped polyester warp yarns with strong binder and filler yarns, creating exceptional strength, stability, and impact resistance. Ultra X1 replaces multi-belts up to and including 400/3 while the X3 version is designed to replace up to 630/3. The higher tensile strength Nova-X uses an even stronger crimped warp fabric with binder yarns to lock the carcass, providing excellent rip, tear, and impact resistance under load. Nova X4 is designed to replace up to 800/4 and Nova X6 can replace up to 1250/4 multi-ply belts. For the toughest applications of all, there is the heavier duty UsFlex, which employs a “Straight warp” carcass made of high-tenacity polyester fibres protected by polyamide weft lines.

All X Series fabrics are designed on the principle of lengthwise longitudinal strands with heavy strands running crosswise, held in position by a strong yarn. The strands are completely straight in both directions and not interlocked as in conventional fabric, allowing the weft to float free from the warp. This creates a shock absorber effect by dissipating impact energy over a larger area, enabling the belt to withstand the kind of punishment that would destroy a normal multi-ply belt. Arguably even more important is the ability to resist rip and tear damage.

When penetrated and being pulled through a strong, sharp, trapped object, the unique weave design allows the strands to gather in a bundle that can eventually become strong enough to stop the belt or even expel the object causing the damage.

Synthetic plies are usually more effective than steel when it comes to minimising the length of a rip. In fact, the UsFlex fabric is so strong that Fenner Dunlop use it as a breaker ply in their steel cord belts.

Greater splice efficiency

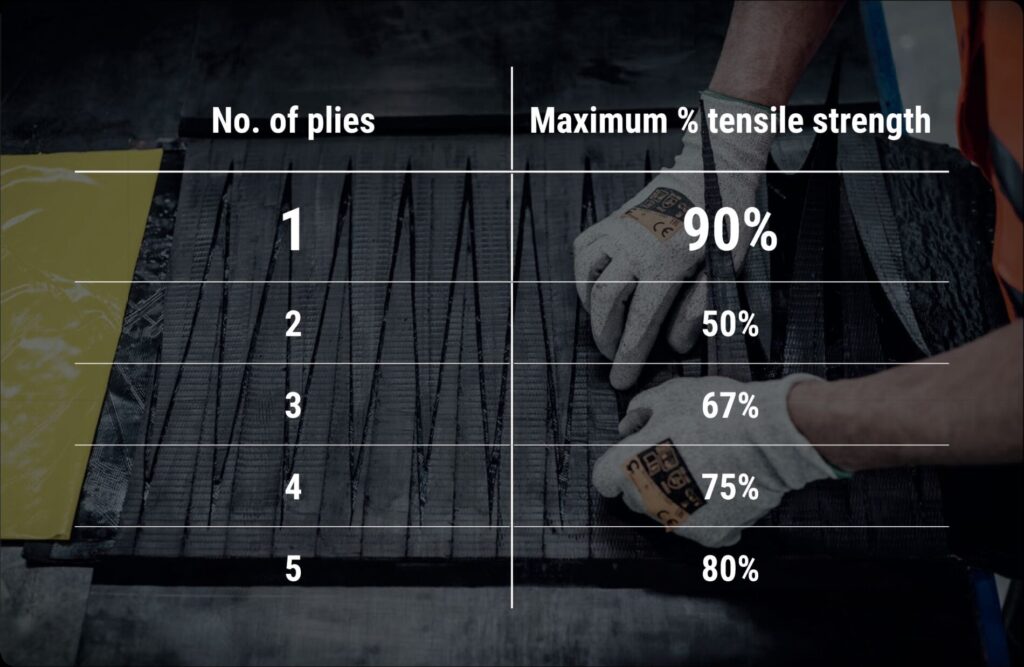

The idea that a single or dual-ply belt can possess the necessary tensile strength and also be considerably more resilient and durable may be difficult for some to comprehend. The answer lies in a combination of the amazing innate strength of the fabrics together with a much higher level of splice efficiency. Although a conventional step splice can be used to join a dual-ply UsFlex, single-ply constructions require a finger-splice joint. The enormous advantage of finger splice joints is that they retain up to 90% of the belt’s original tensile strength.

By comparison, a 3-ply step joint only achieves a maximum tensile strength of 67% while a 2-ply step splice only retains a maximum of 50%. Single and dual-ply belts joined by a step splice create equivalent tensile strengths and belt safety factors that are more than comparable to 3 or 4 layer conventional belting. For example, an Ultra X3 single-ply belt can pull up to 56 tonnes. A significant additional benefit of this method is that finger splice joints are stronger and more durable so the need to repair and re-splice joints is much less frequent.

Another advantage is that X Series single and dual-ply belts are more flexible, so they are also well suited for use on mobile conveyors, which are notorious for having small diameter pulleys. The continual flexing places greater dynamic stress on the inner carcass and splice joint, therefore seriously limiting the strength of belt that can normally be fitted.

Better for the environment

The reduction in environmental impact is also considerable. Having only one or two layers rather than 3, 4 or more layers helps to reduce energy consumption (they are typically 10% lighter) and maximise production efficiency. It also means that less rubber is used, including a corresponding reduction in the chemicals and additives used to make it, together with a dramatic reduction in non-bio-degradable synthetic fabric. The vastly superior toughness also means that they need to be replaced far less frequently, meaning that some 50% fewer conveyor belts have to be manufactured in the first place.

The future is already here

Fenner Dunlop freely admit that the Ultra X single-ply construction did raise a few eyebrows at first but as with all such ground-breaking innovations, it takes time for a new concept to be fully accepted. Judging by the growing sales, that acceptance seems to be spreading very rapidly. UsFlex is long established while Ultra X has proved a great success since its launch some six years ago. Although still manufacturing a big range of conventional multi-ply and steel cord belting, Fenner Dunlop’s management certainly regard their X Series single-ply and dual-ply belts as the future of industrial conveying belting. Given the evidence, the future seems to already be here!