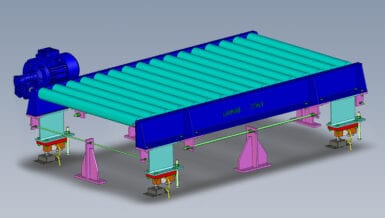

These conveyors are built to heavy duty specifications using Schedule 40 and Schedule 80 carbon steel and stainless-steel pipes. The discs are sized and spaced at intervals permitting conveying throughput rates up to 2,000 cubic feet per hour.

The design of the conveyor, in an explosion absorbing and containing application, will include inert gas blanketing to reduce the risk of ignition and explosion of dust or material emitting explosive gases. Grounding clips at each flange connection will be used to dissipate any static electricity that may be generated while the material is transferred to its destination. Slip on, bolt up, flanged pipe end connectors are used to keep the pipe assembly rigid, and intact while the conveyor is under pressure should an explosion occur. Stainless steel construction can also be adopted to mitigate the risk of sparking should there be any metal-to-metal contact within the conveyor’s moving parts while in operation.

The disc designs are customized to allow explosion energy to abate and dissipate over an extended length inside the conveyor. An extended number of discs will distribute the energy of an explosion over a much larger surface area. The explosion energy is contained through the discs baffling effect as the discs in proximity of the point of ignition pivot allowing energy to run upstream and downstream from the source of ignition. Vent ports are added to the design at set distance intervals to allow excess pressure build-up within the conveyor to blow-off, relieving and limiting the internal pressure within the conveyor should it have to retain and absorb explosive forces.

These conveyors have been tested and approved for coal dust handling applications. They are used to transfer materials that may and will emit volatile gases posing a risk of ignition and explosion. They are often used in explosion risk applications where volatile dusts and material are being handled. They are used in industries that include mining, petrochemical, baking, chemical, metal processing, and processes with explosive, dust collector transfer applications.

With over 45 years of tubular chain conveyor expertise and know-how, Luxme International delivers custom designed tubular chain conveyors to safely handle and transfer materials with explosive properties.