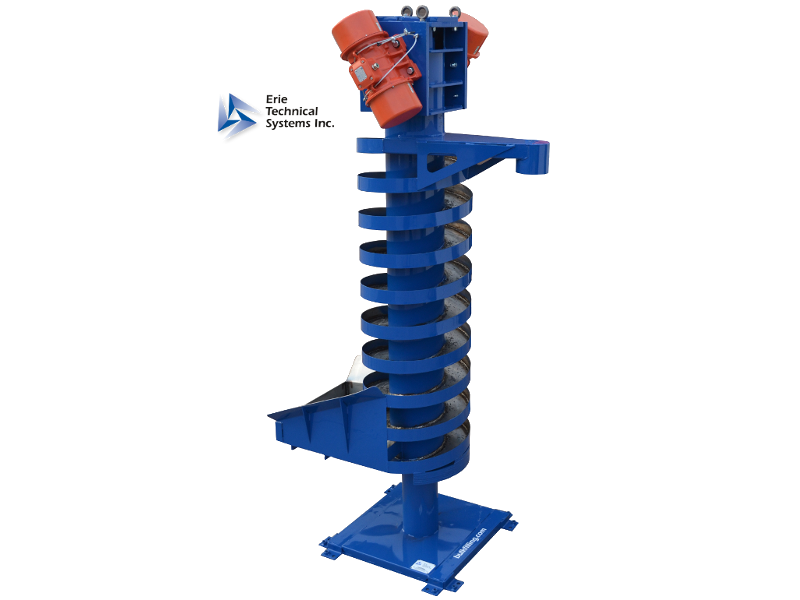

Operating at frequencies between 900 and 1800 RPM, it depends on the product. The conveyor trough, shaped as a spiral and welded to the central drive tube, directs the material upward with specific drive angle and trough pitch for efficient movement.

Advantages

- The vibratory spiral elevator provides a streamlined path for material travel, significantly reducing product damage, contamination, or leakage.

- It features a compact footprint, making it ideal for application with limited space.

- Its smooth surfaces facilitate easy product changes.

- The elevator is designed for easy cleaning.

- Optional soundproofing materials are available to minimize noise levels.

- Maintenance requirements are minimal, with only two rotary electric vibrators and isolators subject to wear.

Conclusion

Vibratory Spiral Elevators are versatile and low-maintenance machines ideal for conveying material. They are easy to clean, save space, and fit into tight areas, eliminating the need for redesigning your process.