From batch mixing systems to large-scale continuous mixing operations, NBE mixers ensure efficient and complete blending of powders, pellets, granules, and other dry solids. NBE process-integrated dry bulk material mixing systems improve overall process performance by providing accurate, repeatable, and reliable material output.

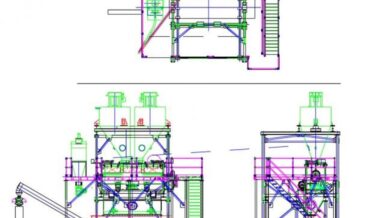

NBE bottom-loading jumbo whirlwind mixing systems are engineered-to-application for mixing processes that require a high degree of finished-material homogeneity and where materials from multiple input sources, such as vacuum systems and bulk containers, are being simultaneously introduced. NBE jumbo whirlwind mixing systems feature a scoop-blade design that draws material into the bottom of the auger, helping quickly integrate ingredients and improve flow of materials. A vertical, solid-core auger pre-mixes material as the material is drawn up and out of the center mixing tube. Top-mount, broad-throw dispersion paddles ensure a homogeneous mix of material. The dispersion paddles enable the jumbo whirlwind mixer to effectively handle challenging materials like powders and fine, dry additives. Built to withstand extended duty cycles and harsh environments, NBE bottom-loading jumbo whirlwind mixing systems feature a thick-wall structural framework, heavy-gauge sheet and plate drum construction, and high-performance drive systems. These features enable consistent and reliable mixing performance for batch capacities up to 100,000 pounds.

NBE automation brings system-wide control, monitoring, and reporting to bulk material mixing applications; whether communicating with new or legacy systems; or providing project owners tangible data for optimizing material mixing and blending cycle times. NBE bulk material mixing systems are engineered to be configurable for specific application requirements. With a broad selection of design features and accessory components, NBE bulk material mixing systems can meet even the most demanding process and compliance requirements.