Optimized Fill Times Deliver More Batches

Over an 8 hour shift the average rate of manually opening and dumping powders from 25 kg bags is 1 to 1.5 bags per minute. As operators tire over the course of their shift, bag opening rates drop. Also, the shaking of bags to clean the bags of residual material trapped in creases or folds becomes secondary to filling mixers or blenders as fast as possible. The result is longer filling times that increase the time it takes to mix or blend a batch. The manual slitting and emptying activity also lead to higher waste rates as excess material is left in the empty bags. A proven solution to remedy these inefficiencies, is to adopt automatic bag slitting technologies. These technologies open and empty bags at rates of 4 to 6 bags per minute while delivering bag emptying efficiencies of 99.95 to 99.99%.

Large batches of 3,000 kg made up of 25 kg bagged powder ingredients will require 80 minutes to manually load 120 bags into a mixer. Instead of manually filling a mixer at 1.5 bags per minute, loading the same batch with an automatic bag slitter at 6 bags per minute will take 20 minutes. The mixing process is now releasing 1 additional hour of productivity per batch to the mixing line. The result is a significant gain in production over the same mixer over the course of a year. If your producing 9 batches per day over a 24-hour shift and are now cutting the mixer cycle time 1 hour every batch, the mixer will produce 3 more batches per day. That same mixer or blending line’s productivity has increased 3 batches or 9,000 kg per day of finished product. Over the course of a year the revenue and profit over that mixing/blending line is significantly increased. For a high-volume line with product sold at good margins the financial benefit of adopting automatic bag slitting is measured in millions annually.

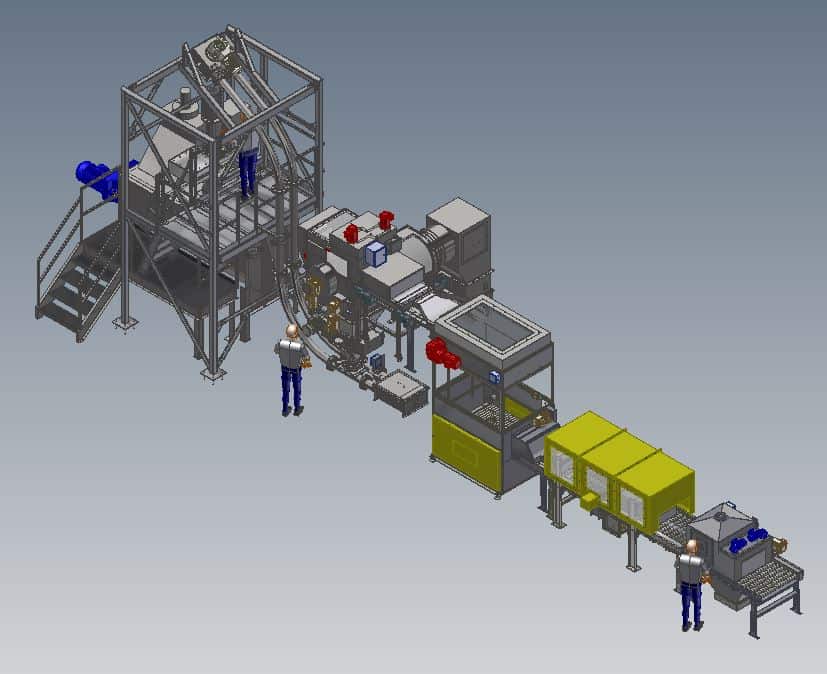

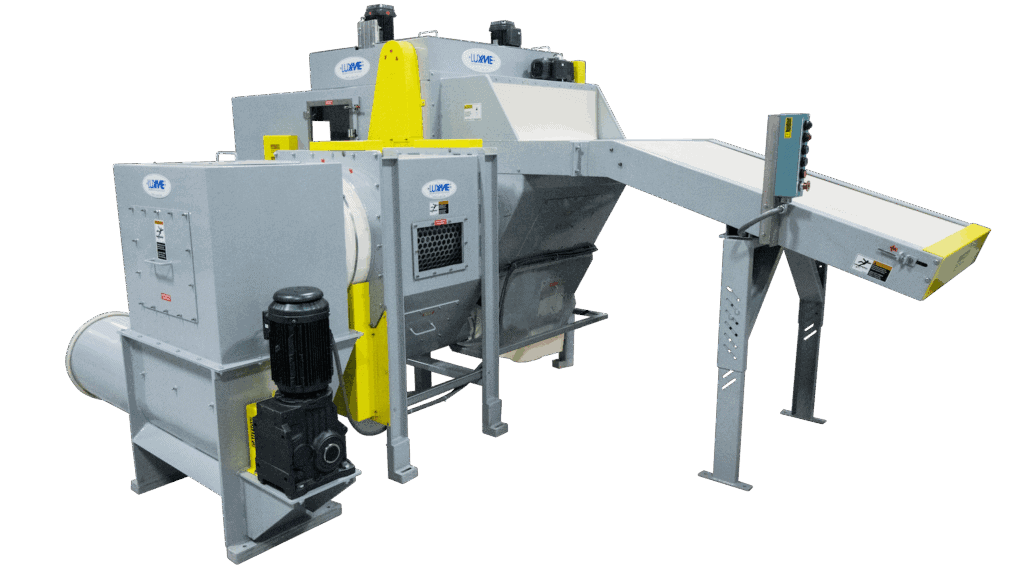

To realize this potential, automated bag slitting lines are often made up of a bag cleaner, conditioner, slitter and conveyor to transfer free-flowing powder ingredients into the mixer or blender. Slitters automatically adjust to bag size, format and material. Bags of multiple sizes, designs and materials are handled by these slitters without having to make any slitter set up changes. This is important for batches where multiple 25kg or 50 kg bagged ingredients make up a recipe to be mixed or blended into finished product.

Sifters or screens are always used downstream to capture any impurities prior to dry powder packaging or prior to blending the powders with liquids. Automatic bag slitting lines are designed for both food and industrial applications. They are adopted where bag processing volumes are high, or when the cost or value of the bagged materials are high.

Higher Material Recovery Optimizes Mixing and Blending

When mixing or blending high value ingredients the automatic bag slitter will again optimize the mixing and blending process with its high material recovery efficiency of 99.95% to 99.99%. In the application outlined earlier where 3,000 kg batches were being produced, material wastage rates above 3% were being recorded. With bags manually slit, opened, and emptied as fast as possible into the mixers the emphasis was to keep fill times short and get the mixers mixing.

With this mixing line realizing a 2.5% material recovery improvement over 12 batches or 36,000 kg per day, a material recovery rate of 900 kg per day is realized. Annualizing this amount at the material average cost per kilogram results in significant savings.

The recovered material from an automatic bag slitting line can be processed into finished product and sold at margin. The material recovery benefit is twofold with the recovery value of the purchased material plus the addition of the margin revenue from the finished product produced with the recovered ingredients. Having 900 kg of ingredients recovered every day, the business benefits from being able to produce a 3,000 kg batch from free ingredients every 4 days. Over the course of a year, 52 batches of product will be produced and sold from recovered material. The automatic bag slitting technology has higher material recovery rates than what can be consistently achieved in a manual bag slitting and dumping application.

Material recovery efficiency of 99.95 to 99.99% is achieved when the slitting line is fitted with a product recovery attachment. This unit tumbles clean, empty bags coming off the slitter prior to directing the slit bag to a compactor. Multiple yield test results are shown on the chart below.

Automatic bag slitting lines can be set up to suit the mixer or blending operation for many industries. They provide a dust free operation within a closed loop process that ensures no external contaminants mix with the ingredient. These lines are constructed in carbon steel or stainless steel and used in the chemical, pharmaceutical, food, construction material, agricultural, feed, flooring and multiple other industries.

Optimizing mixer and blender with shorter fill times and higher material recovery rates presents operators with a unique opportunity. In high volume and high value ingredient batching processes the payback or return on investment is measured in months.

Dust Free and Low Energy Conveying Into and From Mixers and Blenders

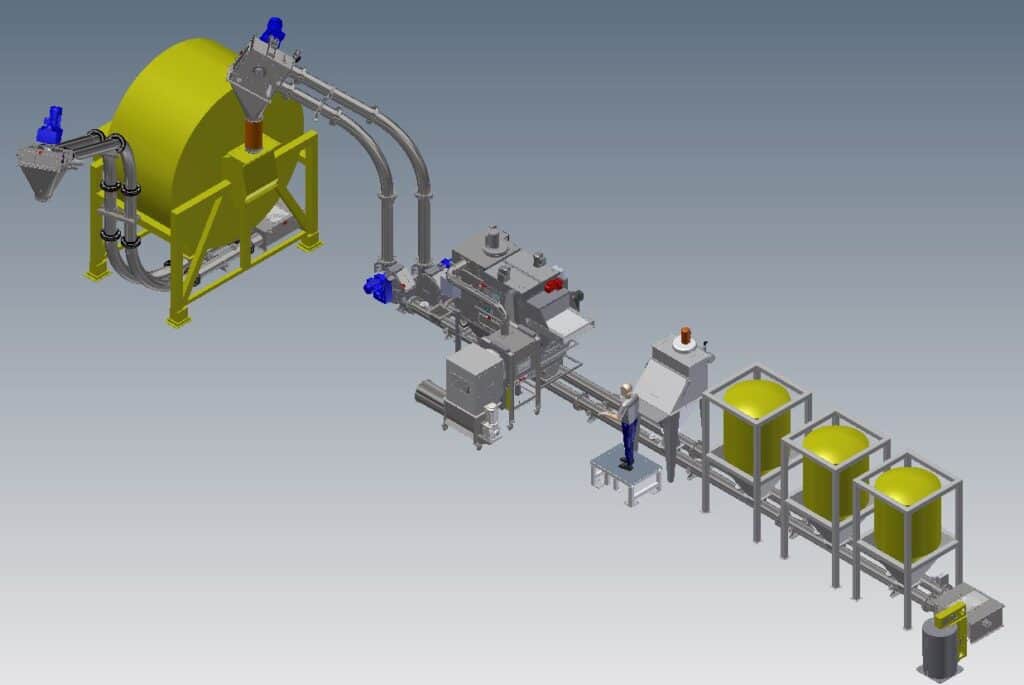

Powders are often conveyed from the slitter to the mixer or blender using tubular chain conveyors. This technology is preferred for its compact, sealed transfer, and dust free design. It allows the slitters to be floor mounted instead of having to be mounted on a stand or mezzanine. The tubular chain conveyors utilize pivoting discs coupled to a flexible chain moving inside a pipe to convey product. It delivers materials from single or multiple inlets to single or multiple outlets. They run dust free and consume very little energy. The product inside the conveyor is protected from external contaminants and delivered without releasing fines to the atmosphere.

These conveyors are used where dust and odor must be kept within the system and not vented to atmosphere therefore keeping work areas clean. When in proximity to personnel work areas, tubular chain conveyors maintain a safe and sanitary workspace.

Tubular chain conveyors offer flexible transfer geometries and process related solutions. It accommodates multiple layouts, and throughput options handling product without degradation. Conveyors are built in carbon steel and stainless-steel to match the slitter material product contact requirements. They are used in industrial and food/sanitary applications complete with washdown options.

The design emphasis is to efficiently move powdered ingredients in an optimized and reliable manner that will optimize the mixing and blending process. Maintaining a dust-free environment is important for safety, keeping external contaminants away from ingredients to ensure quality batches. With over 45 years of automatic bag slitting and tubular chain conveyor expertise, Luxme International designs and manufactures custom designed mixer and blender feed systems which can greatly improve productivity.