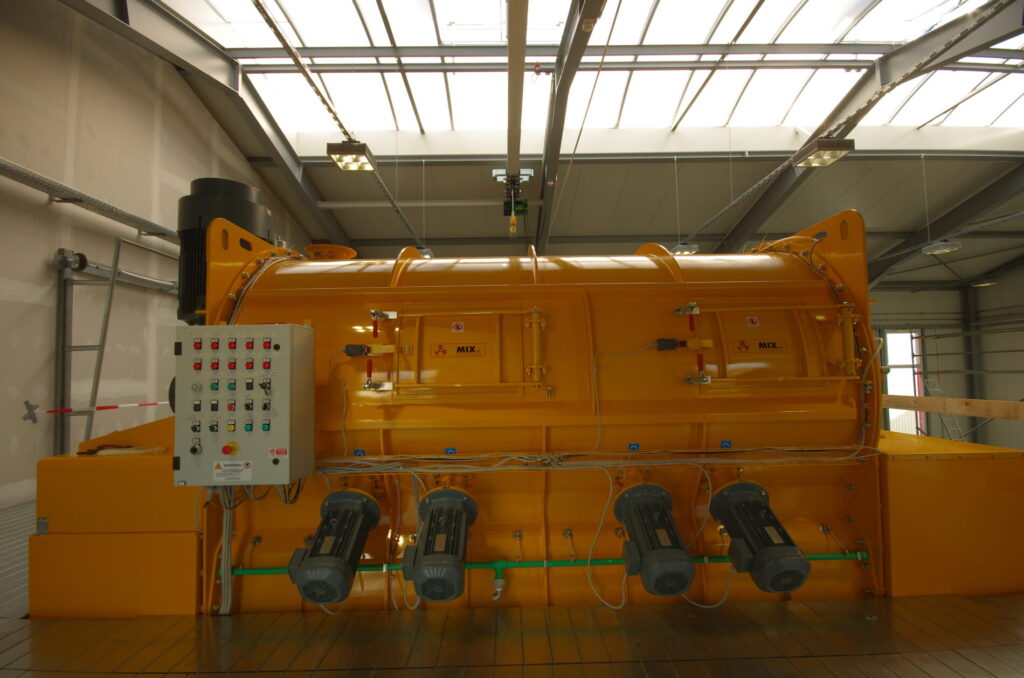

The MXC9500 mixer is designed to meet these needs, offering a unique combination of full-length bomb bay door and automatic dynamic cleaning of the mixing chamber.

Key features:

Stainless steel AISI 304 construction with satin finish: with an internal roughness of 0.3–0.4 microns, it facilitates material discharge, minimizes residue on surfaces, and ensures maximum cleaning efficiency.

7.000 liters batch capacity with side choppers: reduces mixing time while ensuring high-quality homogenization.

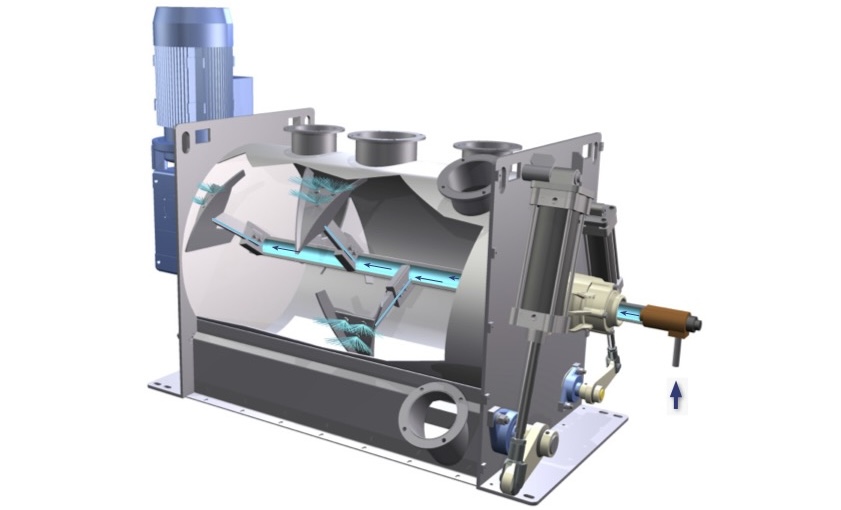

Full-length bomb bay door with 60° opening: allows the batch to be emptied completely in seconds, preventing material accumulation and dead zones. The ready-to-discharge hopper and extraction screw ensure uniform transfer of product to the next process stage, even while the next batch is being mixed.

Dynamic cleaning of the mixing chamber: achieved by injecting compressed air through nozzles located at the tips of the ploughs or paddles. The air is delivered in short pulses from an accumulation tank, effectively removing even the last traces of material, ensuring a completely clean chamber without manual intervention.

The combination of the bomb bay door and dynamic cleaning ensures that even the smallest traces of product are removed. This technology is particularly valuable in processes with frequent formulation changes, where reducing or eliminating manual cleaning saves time, minimizes downtime, and increases overall line productivity.

The MXC9500 mixer with dynamic cleaning is a versatile solution suitable for any mixing process where continuous production, fast batch changeover, and efficient cleaning are critical, without compromising the final product’s quality.