Pneumatic Conveying

Our latest E-mail campaigns for Pneumatic Conveying

- Advancements in Pneumatic Conveying: Latest Insights January 29, 2026

- Pneumatic Conveying: New Insights and Case Studies September 11, 2025

- Pneumatic Conveying E-Product Update May 15, 2025

- Pneumatic Conveying E-Product Insight: Latest Edition January 23, 2025

Experts for Pneumatic Conveying

Todd Allison

Progressive Products, IncTodd Allison is President of Progressive Products, Inc, where he spent 6 years being a sales engineer before moving into his current role. He is also a former adjunct professor in the Kansas Technology Center at Pittsburg State University, where he taught Innovation Engineering. Todd has spent most of his career in the pneumatic conveying industry and has almost 20 years of experience in industrial sales and product design. He is a graduate of SCAD design school and attended graduate school at the Kelce School of Business at Pittsburg State University. He serves on several advisory boards including the CEDBR Kansas Economic Outlook Team and the Mid America District Export Council.

Doan Pendleton

VAC-U-MAXDoan Pendleton is the President of VAC-U-MAX, located in Belleville, New Jersey. With over 35 years of experience in the design, engineering, manufacturing, and marketing of bulk material transfer systems and industrial vacuum cleaning systems, Mr. Pendleton has developed extensive expertise across multiple industries, including food, pharmaceutical, nutraceutical, plastics, chemical, packaging, and additive manufacturing/3D printing. His technical acumen has driven innovation and operational efficiency, playing a key role in advancing bulk material handling technologies. Mr. Pendleton holds a Bachelor of Science degree in Marketing and Management from Suffolk University.

Sami Koskela

LaitexSami Koskela is the Head of Business Unit at Laitex, a Finnish expert company specializing in bulk material handling solutions for demanding industrial applications worldwide. For over a decade, Sami has been solving complex bulk material handling challenges across industries such as energy, wood processing, chemicals, mining and environmental technologies. In his current role, Sami is responsible for driving complex, turnkey material handling solutions, managing the entire sales process from early-stage customer engagement to final contract negotiations. He works closely with cross-functional internal teams and key external stakeholders to ensure the delivery of tailored, value-adding solutions that meet each customer’s specific process and material requirements. Sami plays a key role in helping customers overcome challenging bulk material problems by combining technical insight with practical project experience. He is well prepared to discuss, analyze, and recommend customized, full-scope material handling solutions for a wide range of demanding applications.

Paul Malcolm

Pneuvay EngineeringPaul Malcolm, General Manager of Engineering at Pneuvay Engineering, has been with the company since 2008. He is a highly experienced and qualified engineer, holding both advanced and associate diplomas. Paul is an expert in designing lean and dense phase pneumatic conveying systems and works by the motto, “Excellence is not a skill, it is an attitude”. Outside of work, he enjoys fishing with his son and playing with his daughter.

George Bougioukas

Acmon SystemsGeorge Bougioukas, Plant Manager of Acmon systems has over a 20 years of experience in plant process design for both mechanical and automation engineering in a wide range of industrial sectors. He has gained a unique knowhow of cross-cutting technologies and applications bringing the organization to reach a new industrial value chain era. George’s expertise includes applications ranging from reception and storage of raw materials, pneumatic and mechanical conveying, sieving, weighing and dosing, mixing, up to bagging and final product dispatch. Behind George there is a dedicated team of engineers who like him are constantly striving to improve design and performance of all plants Acmon systems has been delivering all around the globe for the last 30years on a turnkey basis.

Tim Llewellyn

Flexicon CorporationTim Llewellyn is the Global Director of Sales at Flexicon Corporation, a world leader in the design and manufacture of bulk handling equipment and custom-engineered systems. He has over 20 years of experience managing and delivering complex global projects within the bulk material handling industry, including expertise across multiple sectors, including food, chemical, pharmaceutical, nutraceutical, and plastics. Tim has a proven track record of building and managing teams focused on helping clients solve their powder handling challenges. Tim holds a Bachelor of Science degree in Mechanical Engineering from Lehigh University.

Sylvain Bellamy

Tetra Pak Powder Process & TechnologySylvain Bellamy is currently the Commercial Director for Powder Process and Technology at Tetra Pak, based in France. With over 25 years of specialized experience in powder processing, handling, and packing, Sylvain has held various roles across the Americas and Europe, providing him with a comprehensive understanding of the global market. Sylvain's robust background in the food processing industry has sharpened his powder expertise during his years at Tetra Pak, where he contributed to developing innovative powder processing solutions. He leverages his extensive experience to drive strategic growth and operational excellence, always ensuring the delivery of cutting-edge technology and solutions that bring innovations to the market. Contact: Sylvain.Bellamy@tetrapak.com

Alex McCans

HammerTek CorporationAlex McCans is National Sales Manager for HammerTek Corporation, manufacturer of the innovative Smart Elbow Deflection Elbow. With over 10 years of experience in mechanical and pneumatic conveying of bulk solids, Alex leads the HammerTek sales team to solve conveying challenges for customers around the world. His expertise and dedication have helped establish HammerTek as a trusted leader in the industry.

Aristidis Melios

Vraykos Mechanical LimitedAristidis Melios is the General Manager at Vraykos & Associates Mechanical Ltd. He holds a Diploma in Mechanical Engineering from National Technical University of Athens, and has more than 30 years of experience in design, engineering and manufacturing of bulk materials handling systems in food industry in Greece and Balkans area. Mr Melios is an expert in managing industrial projects that concern mechanical or pneumatic conveying, weighing & dosing, mixing, dedusting, screening and storaging of food bulk products. He has the experience needed to create a cost efficient turn-key solution for every bulk materials industry. The last years leads the Vraykos company engineering team with success, inserting new ideas and technologies in the field of bulk materials handling systems.

Matthew Bailey – Technical Lead

BFM® Global Ltd.Matthew is a mechanical engineer holding an honours degree from the Auckland University of Technology and has been responsible for BFM® Global’s product development, testing and compliance programme for over 7 years. Matt’s experience is centred on the powder handling industry with a specific focus on flexible connectors, and all the compliance requirements around them. From food to pharmaceutical and all industries in between, Matt works with our Distributor partners, end users and OEMs from Europe, Asia and the Americas to solve application challenges. He regularly attends industry tradeshows around the world and understands the complex requirements of each different market.

Carrie Hartford

Jenike & JohansonCarrie Hartford is the Director of Business Development and Senior Project Engineer in Jenike & Johanson’s office in California. For nearly 2 decades, she has been solving challenging bulk material flow related problems around the world. Typical projects include the analysis and design of bins, hoppers, feeders, and transfer chutes. Previously, she opened and established an engineering office and laboratory facilities in Perth, Western Australia. Internationally she publishes and presents technical papers, participates in conferences, and presents numerous short courses in the field of bulk solids flow. Carrie has a Mechanical Engineering degree from the University of California, Santa Barbara and an MBA from Azusa Pacific University in California. She is a licensed Professional Mechanical Engineer in the State of California.

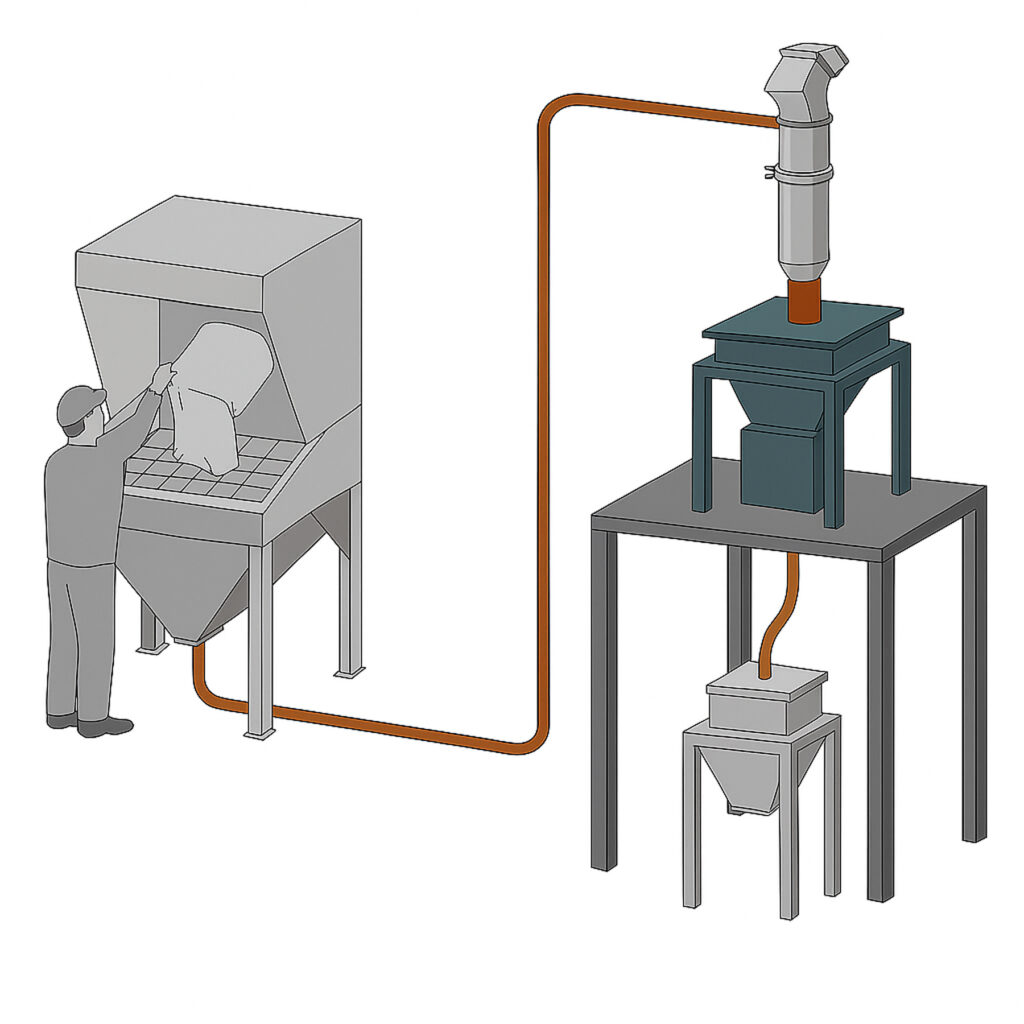

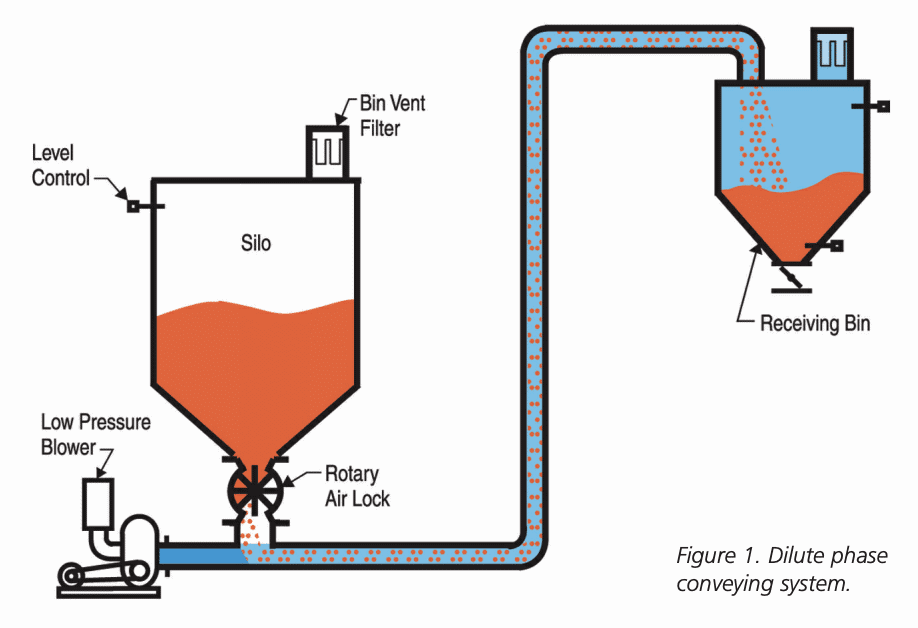

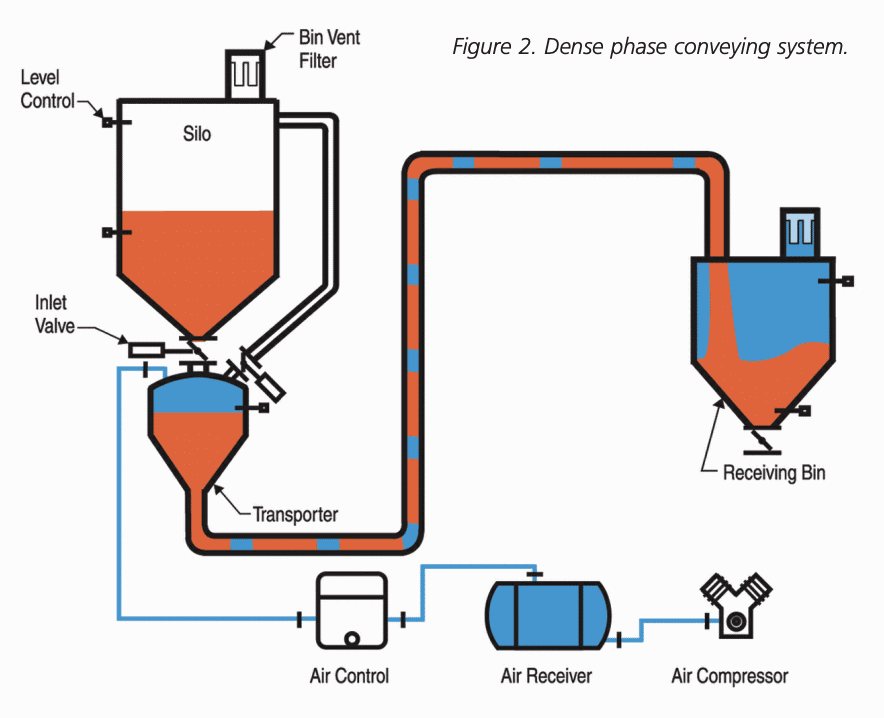

Pneumatic conveying systems transport powders, granules, dry bulk, and flakes through an enclosed conveying pipeline using pressure differential and gas flow (usually air) generated by an air movement device, for example, a roots blower, fan, or compressor.

Pneumatic conveyors provide a cost-effective manner to handle and transfer powdered and bulk granular materials quickly with very little loss. They are suitable for a range of process industries such as; Food and Beverage, Pet Food, Chemicals and Detergents, Renewables, and Specialist Materials.