A leading additive manufacturer approached Elcan after their conventional ultrasonic recycle equipment was discarding large amounts of usable material and forcing them to “cheat the hole” by using a larger mesh opening to try and recover the spent material at its original spec.

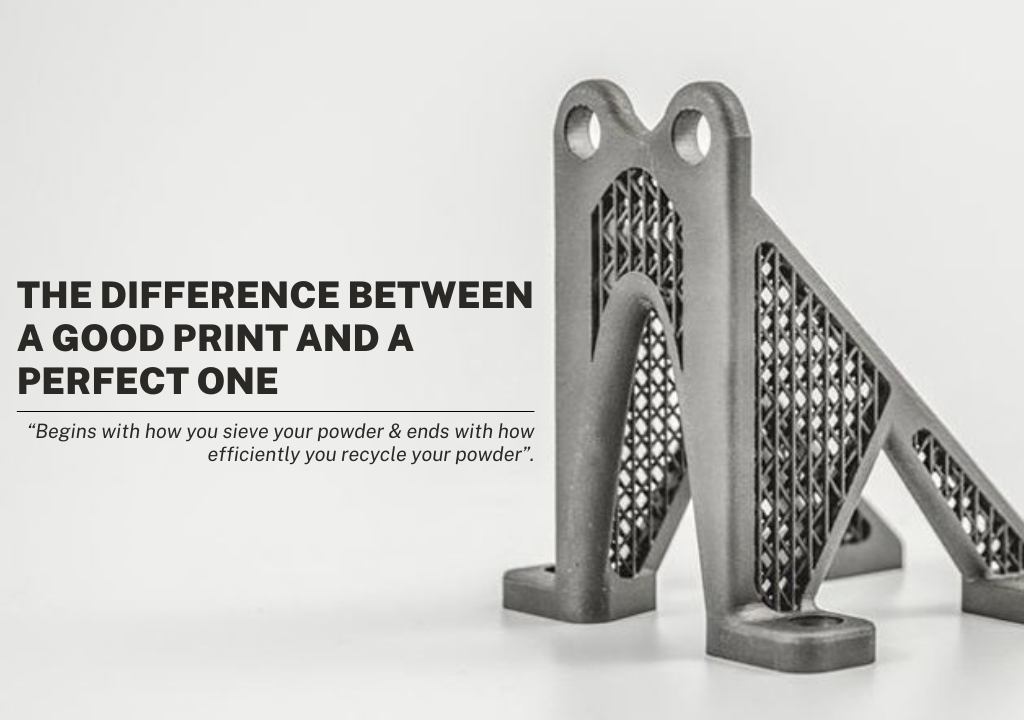

Those workarounds introduce out-of-spec particles, leading to inconsistent melt pools, surface defects, scrap, and most importantly, weaker printed parts. The Hi-Sifter solved the problem by sieving the powder to its original specification, keeping dense titanium powders in continuous motion through vertical high-energy screening. This prevented mesh blinding and allowed the material to be sieved at the original powder spec without the need to “cheat the hole” by increasing the size of the mesh opening, achieving a 96.3% yield in a single pass.

Russell Grotto, Executive Vice President, Elcan Industries, said, “Recovering more than 96 percent of titanium feedstock in a single pass is real-world proof that the high-energy sieving abilities of the Hi-Sifter changes the economics of metal powder production and recycling. Reclaiming material that would otherwise be scrapped reduces cost, shrinks waste, and keeps manufacturers moving at production pace.”

Titanium powder can cost hundreds of dollars per kilogram. Recovering large quantities of material that would otherwise be scrapped translates into immediate, measurable savings. Beyond cost, this result reduces waste, lowers demand for virgin powder, and supports sustainability goals for additive manufacturers and aerospace suppliers.