Industrial sieves and sifters are designed to shake — this motion separates, classifies, or screens bulk materials by particle size before they move to the next processing stage.

But this constant, often aggressive motion can make it difficult to maintain reliable connections. Flexible connectors — which transfer product into and out of the sifter — are placed under significant mechanical stress, especially in continuous operation. Over time, that stress leads to leaks, tears, and unplanned downtime.

Why Clamped Connectors Fall Short on Sifters

Most conventional flexible connector systems struggle to maintain clean, consistent product flow on vibrating or oscillating equipment. The three most common issues are:

1. Constant dust leaks:

Clamped connectors are sealed externally using hose clamps, which inevitably create tiny crevices or gaps. Under vibration or pressure, these become leak points releasing dust and creating potential health and safety hazards.

2. Tears and failures:

Metal clamps, when subject to constant movement, often rub or cut into the connector material over time, leading to premature wear or complete failure. Incorrect installation — whether too tight or too loose — also accelerates damage.

3. Inconsistent length and fitment:

Cut-and-clamp type connector systems rely on manual measurement, leading to inconsistent connector lengths and multiple adjustments to achieve the right fit. This variability complicates maintenance and increases downtime.

A Proven Alternative: The BFM® fitting System

The BFM® fitting system has transformed sifting and screening operations across industries worldwide.

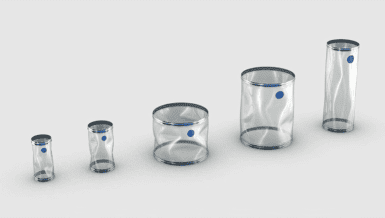

It replaces traditional hose clamps with a snap-fit, internally seated connector. Two stainless-steel spigots are welded to the equipment inlet and outlet, and a flexible BLUEBAND™ connector snaps securely inside them. The unique internal snap-band on each end of the connector expands outward to form a 100% dust-tight seal inside the correspondingly-shaped spigots — no tools, clamps, or guesswork required.

This innovative design delivers a consistent, reliable connection even under vibration, oscillation, or negative pressure — all conditions common in sifting operations.

Why BFM® fittings Excel on Sieves and Sifters

1. Reliable Seal Under Vibration and Pressure

Traditional hose-and-clamp connectors loosen under vibration or pressure changes, creating leaks and dust emissions. In contrast, BFM® connectors seal from the inside, tightening as pressure increases. With no external clamps to loosen or rub, the connection remains airtight and secure.

The result is reduced product loss, cleaner air, and fewer maintenance interventions — critical for plants prioritizing hygiene, product recovery, and safety.

2. Exceptional Durability and Reduced Wear

Sifters are exposed to continuous motion and abrasive materials. Rubber or silicone connectors frequently tear or fatigue under these conditions.

BFM® connectors are made from tough, transparent polyurethane (Seeflex 040E) designed for high flexibility, abrasion resistance, and long service life. Plants using BFM® fittings report dramatically fewer replacements and lower maintenance costs — providing a rapid return on investment.

3. Fast, Tool-Free Changeovers

Downtime costs money. Traditional connectors require tools, clamps, and careful alignment — often taking valuable time to reinstall.

BFM® connectors simply snap in and out by hand in seconds. They are always the correct length and alignment, eliminating installation errors. For maintenance teams, this means faster, safer changeovers and more uptime.

Real-World Results

Mineral Processing Plant — Dust and Downtime Eliminated

A mineral processing facility struggled with frequent hose failures and dust leaks. Each replacement required cutting, clamping, and cleaning — wasting hours of production time.

After installing BFM® fittings, the plant went five months without a single connector failure. Dust leakage stopped completely, maintenance cycles shortened, and connector inventory was standardized. Maintenance teams reported major time savings and easier handling

Soy Flour Processor — Cleaner Air and Safer Operations

A leading food manufacturer in China faced severe dust leakage from silicone connectors on a soy powder line. The screening room filled with airborne flour, forcing operators to wear masks and increasing explosion risk.

Switching to BFM® Seeflex 040E connectors solved the issue instantly. The dust-tight, internally sealed design eliminated leaks, creating a cleaner, safer workspace. Workers no longer needed protective masks, explosion risks were reduced, and efficiency improved thanks to fewer cleanups and longer connector life.

Optimise Your Sifting Operations with BFM® Fittings

For maintenance engineers and production managers, BFM® fittings deliver reliability, hygiene, and ease of use that traditional connectors simply can’t match. The unique snap-fit design ensures a seal that easily handles movement, their durable materials extend lifespan, and tool-free maintenance reduces production downtime.

As proven across industries from minerals to food processing, switching to BFM® fittings can:

- Eliminate dust leaks and product loss

- Simplify maintenance and standardise connector sizing

- Improve hygiene and plant safety

- Boost overall production efficiency

If your sieving or sifting operations still rely on hose clamps and manual fitting, it may be time to rethink your approach. Discover how the BFM® fitting system is revolutionising bulk powder handling worldwide — one connection at a time.