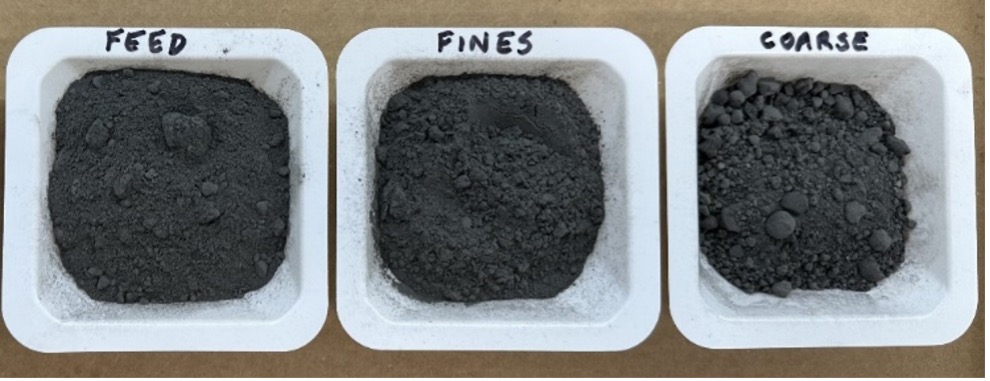

In order to reduce costly disposal of hazardous fly ash in landfills, Sturtevant has supplied numerous air classifiers to coal-fired power plants searching for a cost-effective method of recycling fly ash for use in the production of cement, plaster and concrete. Sturtevant air classifiers separate finer fly ash for use as a supplementary cementitious material (SCM) from larger fly ash, which often contains a greater LOI carbon content.

With the dwindling supply of fresh fly ash from coal-fired power plants, Sturtevant has also supplied numerous air classifiers to companies that harvest previously disposed coal ash. Sturtevant air classifiers separate landfilled fly ash, bottom ash and pond ash to specific particle size distributions needed for use in the production of cement, plaster and concrete. Hence reclaiming a hazardous waste product that can otherwise result in environmental contamination by spilling into nearby land and rivers.

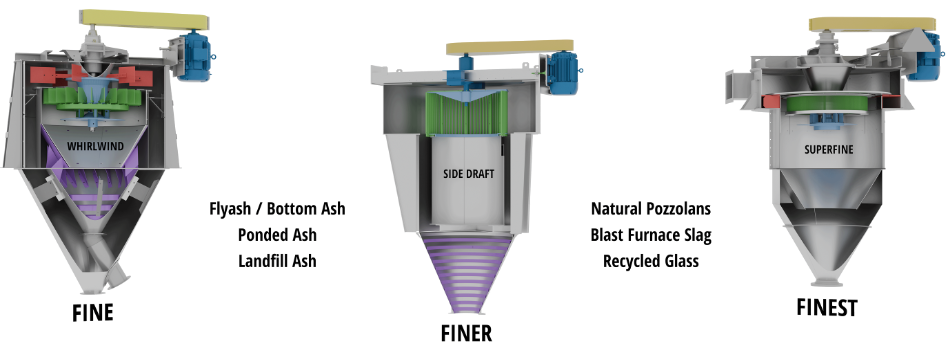

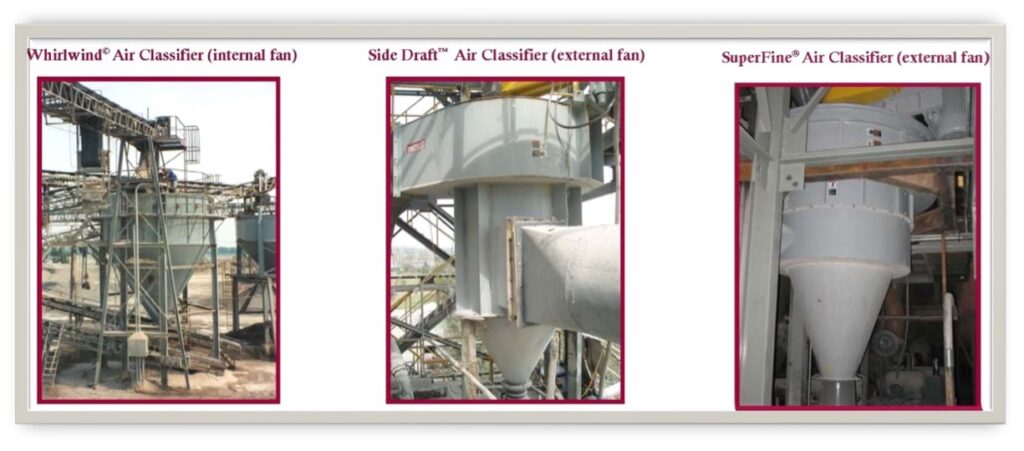

Three Air Classifier Options are available for processing fly ash without the blinding issues associated with screening technology.

Whirlwind Air Classifiers for 100-400 mesh (38-150 µm) product sizes:

- For power plants and harvest sites with consistent source of Fly ash, the Whirlwind is most economical selection

- Internal fan design uses low HP and does not require Cyclones, Airlocks or Baghouse to collect fine products

- Product fineness controlled by internal selector blades, external control valves or by Variable Frequency Drive

- Ash enters by gravity, fine & coarse ash products also exit by gravity

Side Draft High Efficiency Air Classifiers for 100-500 mesh (25-150 µm) product sizes:

- For power plants and harvest sites where source of Flyash or desired Fly ash market specifications vary

- SD Side Draft Air Classifier offers flexibility with particle size controlled by variable speed rotor

- Produces better efficiencies with more versatility than the Whirlwind Air Classifier

- External fan generates system airflow, speed of independent rejecter cage controls product fineness

- Allows quick adjustment to varying feed characteristics to maintain consistent product fineness and quality

- Ash enters by gravity, coarse exits by gravity, fine ash product pneumatically conveyed through rejecter cage and collected in a cyclone or in a dedicated filter receiver baghouse

Superfine Air Classifiers for 5-30 µm product sizes:

- For high value specialty cement additives needing Micro-Flyash PSD with ultra-high strength, ultra-high blaine (surface area) and fast-set properties

- Variable speed rotor with numerous, closely spaced rejecter blades and high-speed operation for ultra-fine and ultra-efficient performance

- External fan generates system airflow, speed of independent rejecter cage controls product fineness

- Allows quick adjustment to varying feed characteristics to maintain consistent product fineness and quality

- Ash enters by gravity, coarse exits by gravity, fine ash product pneumatically conveyed through rejecter cage and collected in a cyclone or in a dedicated filter receiver baghouse

After Ash is harvested from landfills or ponds it must be beneficiated through screening, drying and if necessary milling. But to ensure that the Ash is suitable for use in concrete it must consistently comply with the ASTM C618 Standard Specification for Coal Fly Ash. According to this standard, the maximum allowable oversize particles must be limited to 34 % retained on a 45 µm (325 mesh) sieve.

The Sturtevant Side Draft air classifier achieves this specification with high processing efficiency, as demonstrated in the performance data below.

| Flyash & Bottom AshDried to 0.5% Moisture | Feed Rate(input) | Rejects Rate(output) | Fine Product Rate(output) | ||

| SD-20 Air Classifier | 9 tph | 2.2 tph | 6.8 tph | ||

| Bulk Density | 52 Lbs/cu.ft | 54 Lbs/cu.ft | 52 Lbs/cu.ft | ||

| Max ¼” | |||||

| -100 Mesh (150 µm) | 87.4% | 54.5% | 99.0% | ||

| -200 Mesh (75 µm) | 71.1% | 18.2% | 89.1% | ||

| -325 Mesh (45 µm) | 53.2% | 9.1% | 68.0% | ||

| Retained on 45 µm (325 mesh) sieve | 32.0%Exceeds C618 Spec | ||||

| Separation Efficiency -325 Mesh (45 µm) = 96% | |||||

In this example, the SD-20 Side Draft High Efficiency Air Classifier generated a fine Flyash product with only 32.0% retained on a 45 µm (325 mesh) sieve, which exceeds the ASTM C618 Standard Specification for Coal Fly Ash. The air classifier recovered 96% of the available fines below 45 µm (325 mesh) and this high separation efficiency resulted in only 9.1% fines remaining in the rejects.