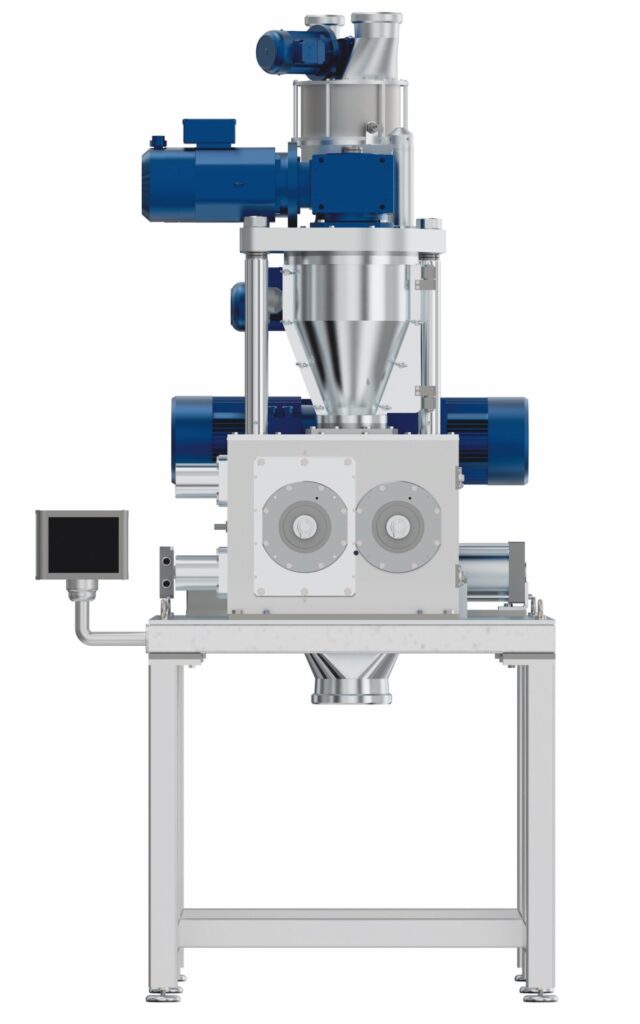

In this context, Lleal has developed the CLL range of compactors, offering versatile and robust solutions capable of adapting to both laboratory needs and large-scale industrial production.

Versatile design: two key configurations

One of the main advantages of the CLL series is that it offers two roller configurations to meet different operational needs:

- The cantilever arrangement allows easy access to the rollers, facilitating replacement and cleaning without the need for specialized personnel. This option is ideal for environments where small batches are handled, frequent format changes are required, or a wide variety of products are processed.

- Models with rollers centered between supports allow much higher pressures to be achieved, making them suitable for products that require more intense and homogeneous compaction. It is the ideal choice for continuous production.

From R&D to industrial production: a complete range

Lleal’s CLL range covers a wide spectrum of production needs: from low-capacity equipment for laboratory environments to high-pressure solutions for large production lines. Among the most compact models is the CLL-112, ideal for R&D applications or pilot plants, with a capacity of up to 30 kg/h and a linear pressure of 20 kN/cm. For intermediate scales, the CLL-224 model offers outputs of up to 350 kg/h and pressures of up to 30 kN/cm, making it an effective option for versatile medium-sized lines.

In the higher performance segment, the CLL-160, CLL-320, CLL-448, and CLL-640models stand out, capable of achieving stable working pressures between 40 and 50 kN/cm, allowing for the processing of a wide variety of products, including those requiring more demanding compaction.

Robustness, precision, and total process control

The CLL range of compactors is designed to deliver high performance in demanding industrial applications. Manufactured entirely from stainless steel, they guarantee durability, corrosion resistance, and ease of cleaning. Some models can achieve linear pressures of up to 40–50 kN/cm, with compaction forces of around 500 kN, making them a reliable and robust solution for the continuous processing of dry solids.

Precise feeding and pressure control

The feeding system incorporates two independent spindles:

- The horizontal screw maintains a constant flow of product to the hopper.

- The vertical screw regulates the pressure with which the material is fed to the rollers.

This dual feed allows for separate control of the input flow and compaction force, optimizing process performance and precision.

When the material is clumped or lumpy, a pre-feeder granulator can be integrated to ensure adequate homogeneity before compaction.

In addition, they have cooling or heating systems integrated into the rollers, designed to adapt to temperature-sensitive materials. They also have a mechanical adjustment of the separation between rollers, which allows minimum distances to be set according to process specifications.

The pressure between the rollers is controlled by a pneumatic-hydraulic circuit, controlled from the control panel. A programmable electro-pneumatic regulator keeps the pressure stable throughout the operation, even in the event of product variations.

Automation and traceability: total process control

The CLL range of equipment can operate using product-configurable recipes, facilitating process standardization and reproducibility. Once the recipe has been selected, the system can operate in automatic mode, adjusting the feed speed in real time according to variations in the powder particle size.

At the end of the cycle, the system generates a complete production report, including parameters such as rotation speeds, working pressures, distances between rollers, and electrical consumption. This functionality provides operational traceability and facilitates compliance with quality and validation regulations.

Advantages of the dry granulation process

Dry granulation is one of the most effective technologies for transforming powders into granules without using solvents or binders. The process is divided into two stages: compaction using rollers to form plates or briquettes, followed by granulation by crushing and screening to define the final particle size.

The benefits of converting powder to granules are numerous:

- Improved handling and dosing of the product.

- Greater stability against humidity in hygroscopic materials

- Reduction of airborne dust and minimization of health risks for operators

- Increased flowability in hoppers, screws, and other feeding systems.

- Prevention of segregation of the active ingredient in complex mixtures.

- Higher density of the final product, with increases of up to 5 times, which improves packaging and transport.

Furthermore, by not using liquids or additional excipients, the risk of modifying the original product formulation is avoided.

Direct application in tablet manufacturing

Dry granulation is particularly useful in the production of pharmaceutical tablets from low-density powders. This process:

- Improves the uniformity and quality of the tablet.

- Facilitates compression, even without the need for additional binders.

- Optimizes the dissolution and disintegration of tablets in the body.

Thanks to these advantages, Lleal’s CLL compactors integrate perfectly into granulation and compression lines, providing an efficient and reproducible solution for the formulation of solid oral dosage forms.

Efficient compaction

The new range of CLL compactors from Lleal combines mechanical robustness, process control, and wide adaptability to different sectors and products. Its different configuration options make it an essential tool for the production of high-quality granuleswithout the need for liquids or excipients.