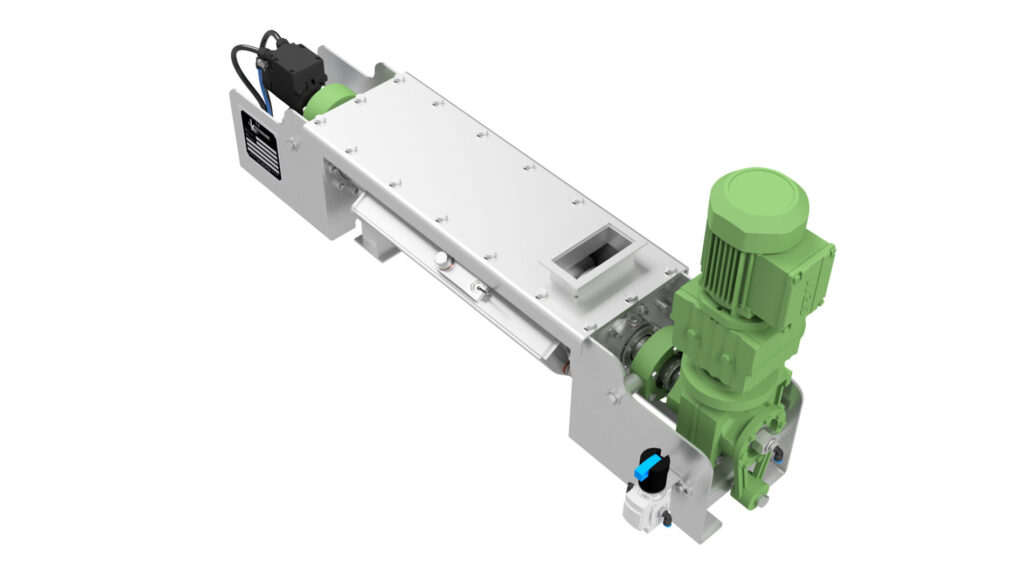

Our patent-pending technology, featuring a liquid metal core, achieves a previously unattainable level of efficiency and homogeneity in heat transfer. The LiquiCore™ High-Temperature Screw Heater reliably combines the transport of bulk solids with precise thermal treatment—but at a completely new temperature level and with significantly simplified infrastructure.

Closing the Gap: From PFAS Remediation to Pyrolysis

In the fields of environmental technology and recycling, the LiquiCore™ closes a critical gap between conventional thermal screws (limited to ~350°C) and complex rotary kilns. The ability to operate stably between 500 °C and 600 °C opens up two crucial applications:

- The Answer to the PFAS Challenge: The system reaches the precise temperatures required for the effective thermal desorption of PFAS (per- and polyfluoroalkyl substances). This allows for the reliable removal of these “forever chemicals” from sewage sludge, contaminated soils, or spent activated carbon directly on-site (end-of-pipe), ensuring regulatory compliance without the high energy footprint of incineration.

- Advanced Recycling & Pyrolysis: This temperature range is also the “sweet spot” for manyWaste-to-Value processes. The LiquiCore™ enables the continuous pyrolysis of biomass, mixed plastics, or composite materials to recover valuable resources such as biochar, pyrolysis oil, or recovered carbon black (rCB) in an oxygen-depleted environment.

Your Advantages at a Glance:

- Process Temperatures up to 600 °C – Unlock new process windows for PFAS desorption, pyrolysis, and calcination that are not feasible with thermal oil systems.

- Maximum Energy Efficiency – Direct electrical heating and the highly conductive liquid metal core minimize energy losses and ensure extremely fast heat transfer to the bulk material.

- Greatly Simplified Infrastructure – The LiquiCore™ only requires a power connection. Complex peripherals such as thermal oil heaters, steam boilers, insulated pipelines, and pumps are eliminated.

- Minimized Maintenance – No thermal fluids mean no leaks, no fluid degradation, and no complex inspections of pressure vessels. The system is robust and operationally reliable.

- Sustainable and Eco-Friendly – Operation with (renewable) electricity enables a low-CO₂ process. There are no hazardous thermal oils to dispose of.

- Precise Process Control – Electrical heating allows for exact temperature regulation, ensuring consistently high product quality—crucial for sensitive pyrolysis processes or regulatory proof of PFAS removal.

How It Works

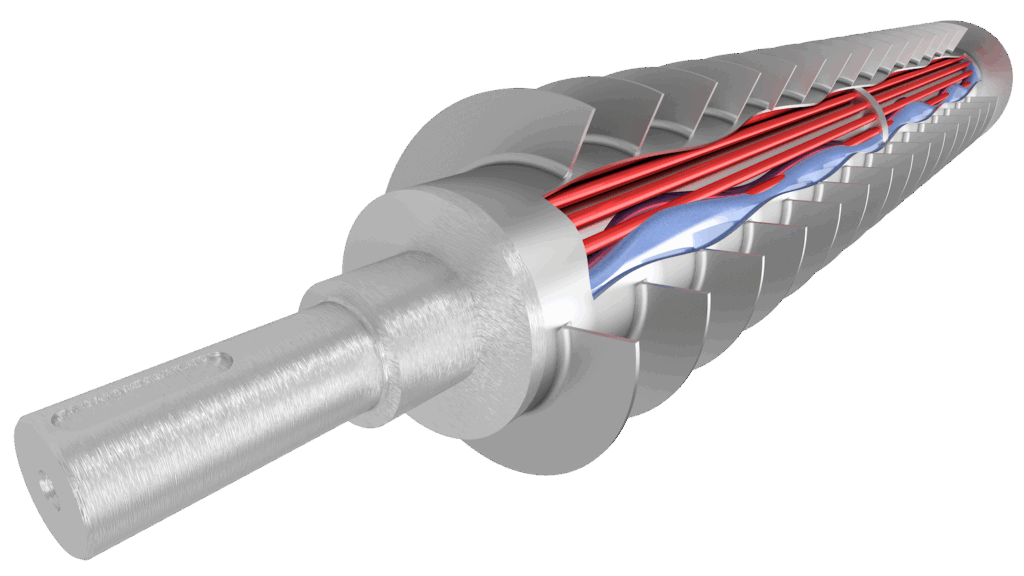

The heart of the patent-pending LiquiCore™ technology is an innovative design of the screw shaft. Inside the shaft, electrical heating elements are embedded in a hermetically sealed core containing a special, low-melting-point metal.

In its operating state (approx. >230 °C), this metal is liquid and serves as an ideal heat transfer medium. Due to its extreme thermal conductivity, it distributes the energy generated by the heating elements instantly and uniformly across the entire length of the screw shaft. The bulk material is conveyed and continuously mixed, ensuring intensive contact with the tempered surfaces. Optionally, the trough jacket can be heated using the same principle to maximize heat input.

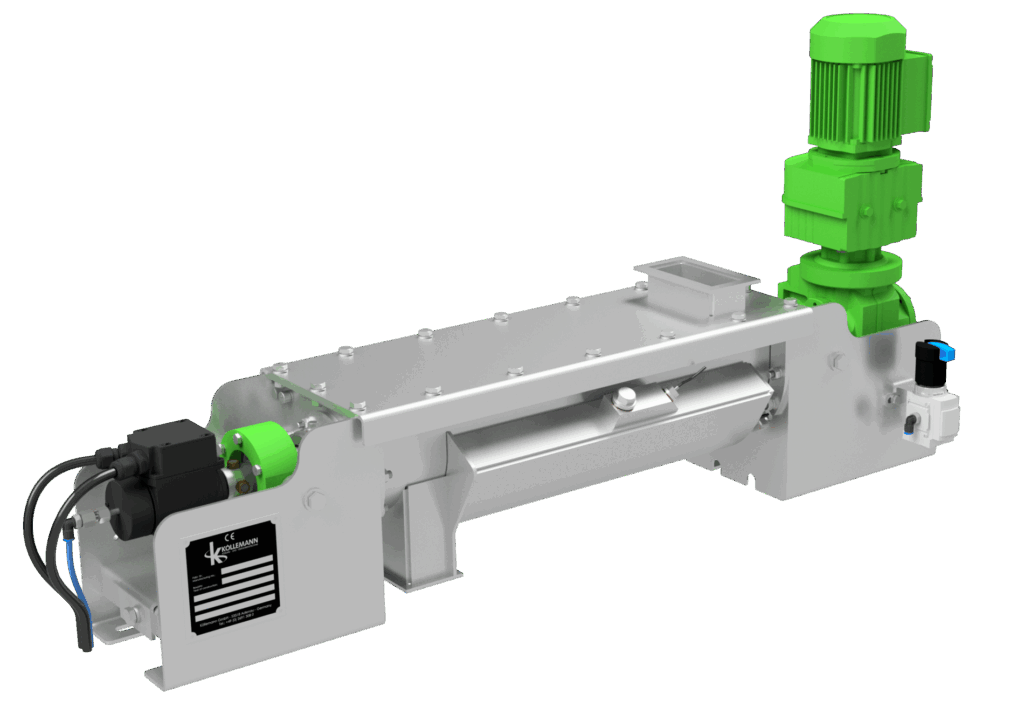

Designs and Customization

Every LiquiCore™ High-Temperature Screw Heat Exchanger is a tailor-made solution that we adapt precisely to your process:

- Materials: Use of high-temperature resistant stainless steels and special alloys, selected according to temperature and product properties.

- Geometry: Screw diameter, length, and pitch adapted to the specific process.

- Trough Design: Available as a tubular or U-trough, optionally heated and insulated.

- Control Technology: Fully integrated control and regulation technology for precise process management and monitoring.

Start Small: Affordable Lab-Scale Testing

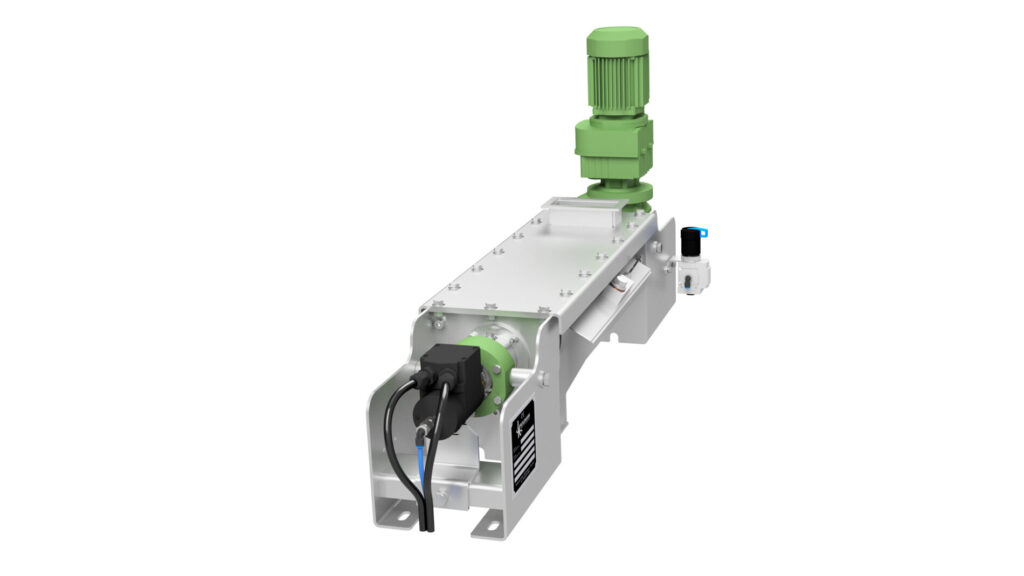

To allow you to validate the LiquiCore™ technology for your specific material at low risk, Köllemann offers a compact, table-sized test machine (approx. throughput 5–15 kg/h).

Designed as a cost-effective entry model, this unit is the ideal investment for your in-house R&D facility. By acquiring this test unit, you gain the flexibility to conduct unlimited trials under realistic process conditions, allowing you to generate reliable upscaling data for PFAS desorption or pyrolysis whenever your project demands it.

Fields of Application

The LiquiCore™ technology opens up new possibilities for a multitude of industries:

- Environmental Technology: Thermal desorption of PFAS from soils and sludges, regeneration of loaded activated carbon.

- Recycling & Circular Economy: Pyrolysis of plastics, tires, or biomass (Biochar production), drying of industrial sludges.

- Chemical Industry: Calcination, thermal activation of catalysts, high-temperature reactions.

- Energy & Raw Materials: Torrefaction of biomass, processing of ores and minerals.

Do you have a demanding thermal challenge? Contact us! Together, we will develop the right process solution based on our innovative LiquiCore™ technology.