Tailored Engineering for Strategic Industries

The ability to deal with the very specific requests of the food, plastic, and chemical industries, combined with our extensive production capabilities, allows us to provide a multitude of solutions for every market need.

To ensure maximum production efficiency, COMAV’s production line is separated into different divisions, providing a vast array of products and services, from the design of bag emptying machines and OCTABIN/Big Bag loading and unloading systems, to pneumatic conveyor valves, stock systems, waste compactors, mechanical conveyors and specialist machinery.

Focus: Industrial Valves for Precision and Control

In particular, valves play a crucial role in bulk material handling, providing controlled and efficient material flow in conveying and processing systems of various sectors.

Our valves are made from high-quality materials such as stainless steel and cast iron for long-lasting performance. They are designed to ensure accurate material flow with minimal leakage and allow quick cleaning, therefore reducing downtime. They’re also available in various sizes and designs to accommodate different industrial needs and are optimized for low power consumption while maintaining high efficiency.

Applications in Various Industries

As previously mentioned, these valves find applications in various industries. For instance, in the food sector, our valves can handle ingredients like flour, sugar, and spices with precision, while maintaining first-rate hygiene. In the chemical sector, they can safely transfer chemicals whilst preventing contamination and leakage and, in the agriculture sector, they can facilitate the transport of grains, seeds, and animal feed.

COMAV offers a variety of valves, such as rotary, diverter, knife gate, and over-/under pressure valves.

Rotary Valves: Design and Features

Our rotary valves are available with rectangular or round flanging, with the exception of our VSFC valve, designed specifically to be installed on semi-trailers and available with rectangular flanging only. They can be used for dosing and pneumatic conveying.

To avoid contamination between different products, we can also offer our rotary valves, with the exception of the VSFC model, in a fast-clean version with manual quick-release rotor removal. Furthermore, for high-temperature applications, COMAV offers a version with spaced bearings and special resistance qualities to suit the temperature and type of product being processed.

The supply of rotary valves with a detachable rotor system has always represented a critical point in the installation of pneumatic conveying.

Case Study: Rotary Valves for Green Coffee Peels

Recently, one of our customers has commissioned us an important order for several rotary valves to be applied in the recovery system for green coffee peels derived from the roasting process. The peculiarity of such installation is a working temperature over 200° C, which COMAV is able to face through an application of a special high-temperature paint, certified EC 1935/2004, and specific components suitable for high temperatures. Moreover, the detachable rotary valve finds its employment in an environment of difficult access. Thanks to our special detachable solution, self-alignment between axis of rotor and housing and rotor’s self-centering, operators won’t have any difficulties with cleaning and replacement, even if the working environment is limited and cramped.

A few examples of our rotary valves:

Diverter Valves: Versatile Applications

Our diverter valves are easy to install and can be supplied in different materials and sizes. They can be used for pneumatic transportation, for the separation of the product in case of storage overload, and in the distribution of gravimetric conveyor lines. Some are two-way or three-way valves, equipped with flexible or rigid tubes, developed to allow a rapid valve change.

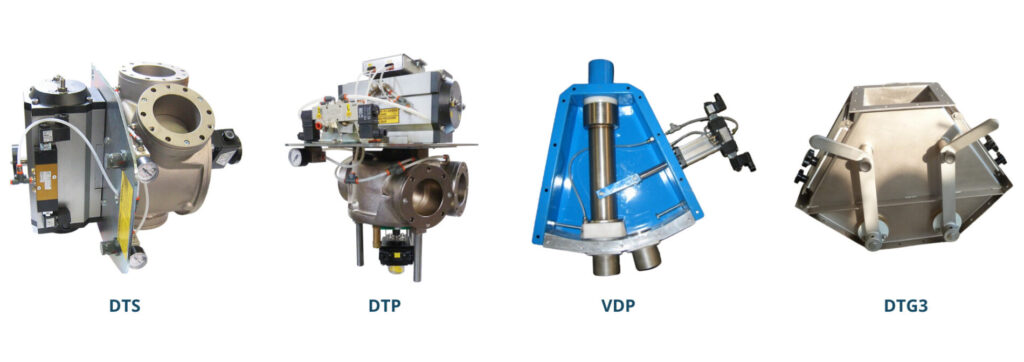

A few examples of our diverter valves:

Knife Gate Valves: Efficient Isolation

Our knife gate valves are used to isolate the stream of free-flowing product, to intercept it under a hopper or silo, and to partialize the product unloading process. They can also feature a self-cleaning blade that prevents accumulation of the product during opening and closing and can be available in a manual version.

A few examples of our knife gate valves:

Over-/Under Pressure Valves: Safety and Protection

Lastly, our over-/under pressure valves are made from stainless steel and are available in a DN 250 universal size. They’re used in tanks, silos, and hoppers to prevent the implosion or explosion of the product-receiving organ.

A few examples of our over-/under pressure valves:

Compliance and Certification

All our valves, except our over-/under pressure valves, are available in MOCA, ATEX, and EAC versions.

Conclusion: Precision, Efficiency, and Durability

In conclusion, COMAV’s valves offer precision, efficiency, and durability, making them an essential component in bulk material handling systems. With a focus on quality and innovation, COMAV continues to provide industry-leading solutions for diverse applications.