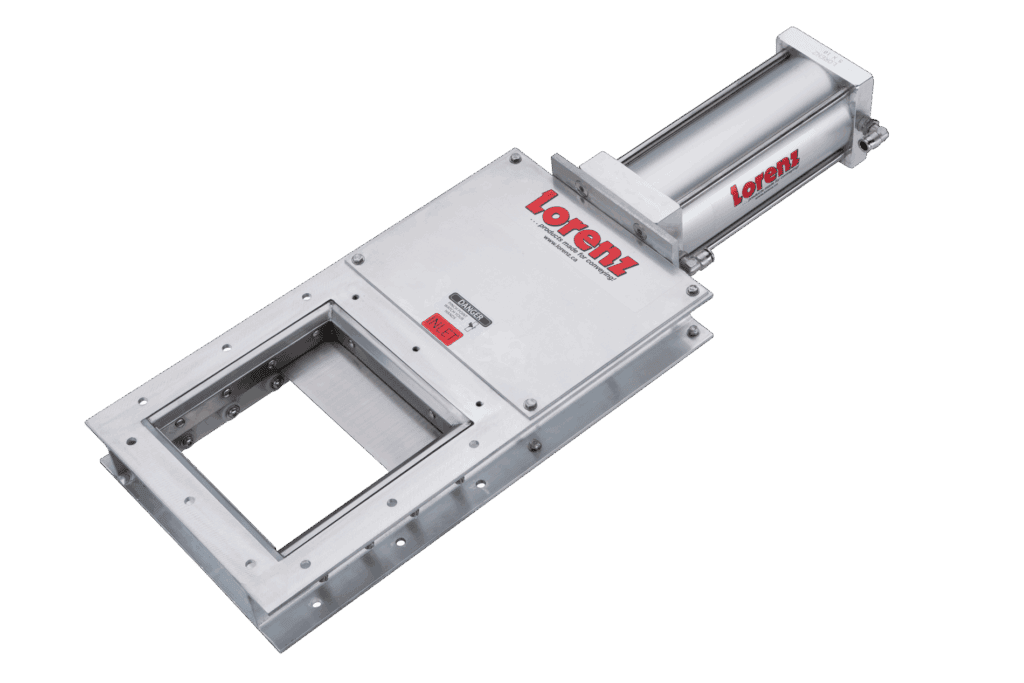

Designed for applications requiring either fully open/close positions or variable positioning, these gates handle dry products efficiently while preventing material from hanging up—thanks to their unobstructed orifice design.

Precision & Reliability in Every Cycle

At the heart of the Lorenz Roller Gate is a commitment to accuracy and longevity. The adjustable nylon cam rollers create a dust-tight seal on the blade, preventing leakage and contamination, even in demanding environments. The Lorenz Roller Gate ensures smooth product flow, and minimizes maintenance requirements. Whether in food processing, plastics, chemicals, grain, or milling operations, Lorenz Roller Gates deliver consistent, repeatable performance.

Built to Fit Your Application

Lorenz understands that every installation is unique. That’s why Regular or CEMA flange patterns are available, ensuring seamless integration into existing systems. Standard construction features aluminum housing with a polished stainless steel blade—lightweight yet durable for long service life. For more demanding or specialized applications, carbon steel or full stainless steel construction options are available.

Additional standard features include:

- Unobstructed orifice ensuring product does not hang up

- Positive Blade Lock (PBL) between blade and cylinder rod for secure positioning

- Internal magnetic piston for enhanced control

- Cushioned air cylinder to reduce mechanical stress

- Stainless steel blade for corrosion resistance and clean product contact

- Temperature rating up to 82º C (180º F) for versatility across industries

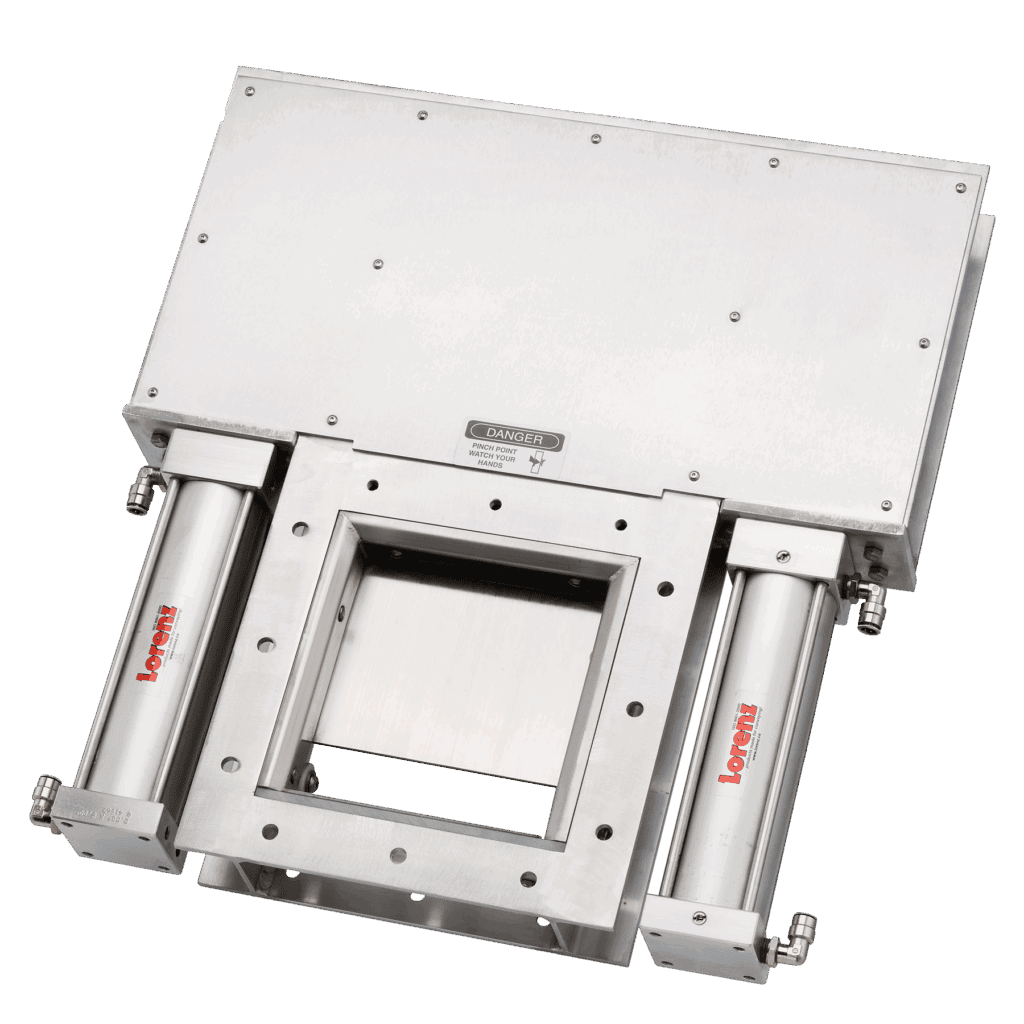

Dual Air Cylinder Roller Gate Options — our Roller Gate, re-engineered into a compact, twin-actuator design for smooth, balanced opening/closing in tight spaces.

Key Benefits:

Offers the flexibility of operating both gates independently or in sequence for optimized flow control

Ideal for Food & Pet Food, Grain, Milling, and Chemical Applications

Handles a wide range of material options — including fine powders, small to large granules, abrasive materials, and even sticky materials.

Maintains the same dust-tight, durable construction as single gates

Compact Solutions Without Compromise

When space is at a premium, Lorenz offers the Dual Air Cylinder Roller Gate—a compact, high-performance solution with all the same quality features as the standard model. This smaller footprint allows for installation in tight spaces without sacrificing performance or durability.

Sizes & Capabilities

Lorenz Roller Gates are available in sizes up to 36 inches, making them suitable for a wide range of applications—from small-scale operations to large, industrial gravity flow systems. Regardless of size, each gate maintains a dust-tight seal and smooth operation to keep systems running efficiently and cleanly.

Industries & Applications

Lorenz Roller Gates are trusted across industries where reliability, hygiene, and precision are critical, including:

- Food & Pet Food Processing – Reliable metering for powders, granules, and blends

- Grain & Milling – Durable operation for high-volume agricultural and milling systems

- Chemical Processing – Corrosion-resistant materials and dust-tight seals for safety and product integrity

- Plastics & Packaging – Smooth, unobstructed orifice for consistent pellet and resin flow

Key Advantages at a Glance

- Unobstructed orifice for smooth material flow

- Dust-tight seal with adjustable nylon cam rollers

- Durable, corrosion-resistant construction for long service life

- Versatile designs including single, dual, and compact configurations

- Handles a wide range of material types from powders to sticky substances

- Customizable flange patterns for easy integration

- High-cycle reliability for demanding applications

With Lorenz Roller Gates—whether single, dual, or compact you get reliable gravity flow control without the blockage. Engineered for performance, built to last, and designed to keep your systems running smoothly, Lorenz delivers proven solutions backed by decades of manufacturing expertise.