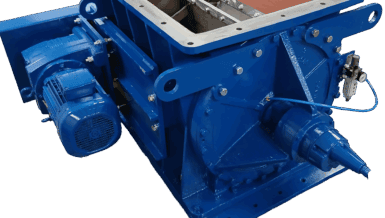

Designed to be mounted above airlocks or below bins and hoppers, these gates isolate equipment during service, creating a safer and more efficient maintenance process for operators across multiple industries.

Built on decades of proven performance, Lorenz Maintenance Gates are trusted throughout the food, pet food, plastics, packaging, grain, milling, and chemical sectors. Whenever equipment must be inspected, repaired, or cleaned, these gates provide a controlled, dependable method to shut off product flow without disrupting the entire system.

Engineered for Maintenance Efficiency

Lorenz Maintenance Gates are designed specifically for periodic shutdown and maintenance of downstream equipment. By isolating material flow quickly and safely, plants avoid costly system-wide stoppages and minimize cleanup, labor, and downtime.

These gates are intended for gravity flow applications only. The narrow profile and lightweight frame allow easy installation even in tight or existing system footprints.

Built for Durability and Clean Operation

Lorenz offers both square models—featuring 304 stainless steel and polymer contact points—and round models built with 304 stainless steel, polymer, and aluminum contact points. This variety ensures compatibility across systems and material types.

To maintain sealing integrity, woven Teflon seals are available as an option for applications requiring enhanced sealing performance. Standard models use durable polymer sealing designed for long-lasting, consistent operation.

Every Lorenz Maintenance Gate is rated to 82°C (180°F), ensuring reliable operation even in demanding thermal environments commonly found in processing plants.

The Smart Choice for Maintenance and Budget Control

By simplifying safe shutdown procedures and reducing unwanted downtime, Lorenz Maintenance Gates help extend equipment life while protecting operational budgets. Plants looking to maximize uptime and streamline service routines rely on Lorenz for rugged construction, dependable sealing, and unmatched performance.

Save your maintenance budget with Lorenz Maintenance Gates — your #1 solution for safe, efficient equipment servicing.