Innovation and performance

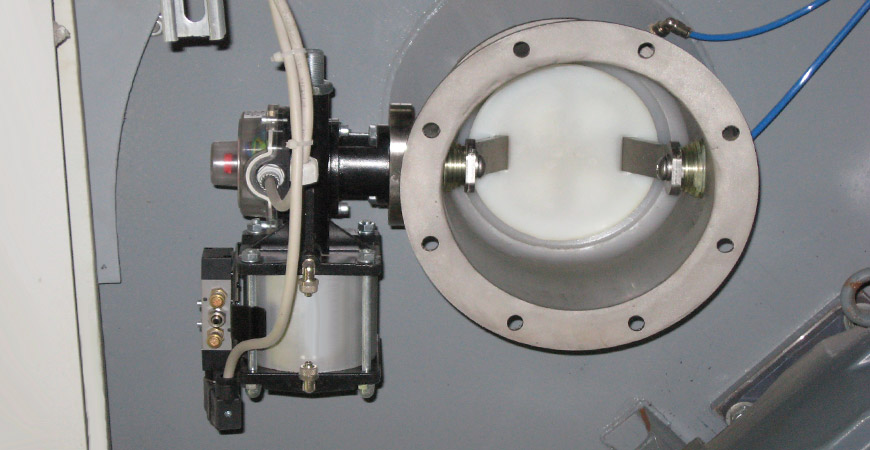

Engineered for efficiency, the VSS Ball Segment Valve ensures a completely unobstructed material flow when open, with its full bore-through design offers superior performance compared to traditional butterfly valves.

Key features and benefits

- Unobstructed material flow: full bore-through design for optimal performance.

- Long-lasting sealing efficiency: for a cleaner working environment.

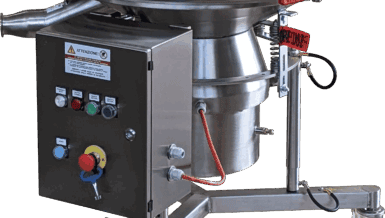

- Compact and hygienic design: ideal for sanitary, pharmaceutical, food and chemical applications.

- Suitable for poorly flowing materials: perfect for compacting powders and hazardous materials.

Industries and applications

Thanks to its versatility and unique features, the Ball Segment Valve VSS well-suited to a wide range of industrial sectors:

- Food industry: flour, sugar, and food powders with high hygiene standards.

- Chemical industry: hazardous powder materials interception

- Tires and plastics Industry: intercepting the flow of powders and granules showing poor flowability.

- Heavy industry: metallic powders and abrasive material handling.

Technical specifications

• Materials: mild steel or stainless steel with replaceable SINT® engineering polymer gasket.

• ATEX-certified versions for explosion-proof environments.

• Compatible with various actuators: manual, pneumatic, and electric motor.

• Dimensions available: 150 ~ 300 mm.

A Strategic investment for production enhancement

The new Ball Segment Valve VSS represents a significant advancement in powder handling and difficult material flow interception, helping to reduce product losses and optimise industrial efficiency. The VSS-type Ball Segment Valve is the best choice for businesses seeking a high-performance, safe, and durable equipment.