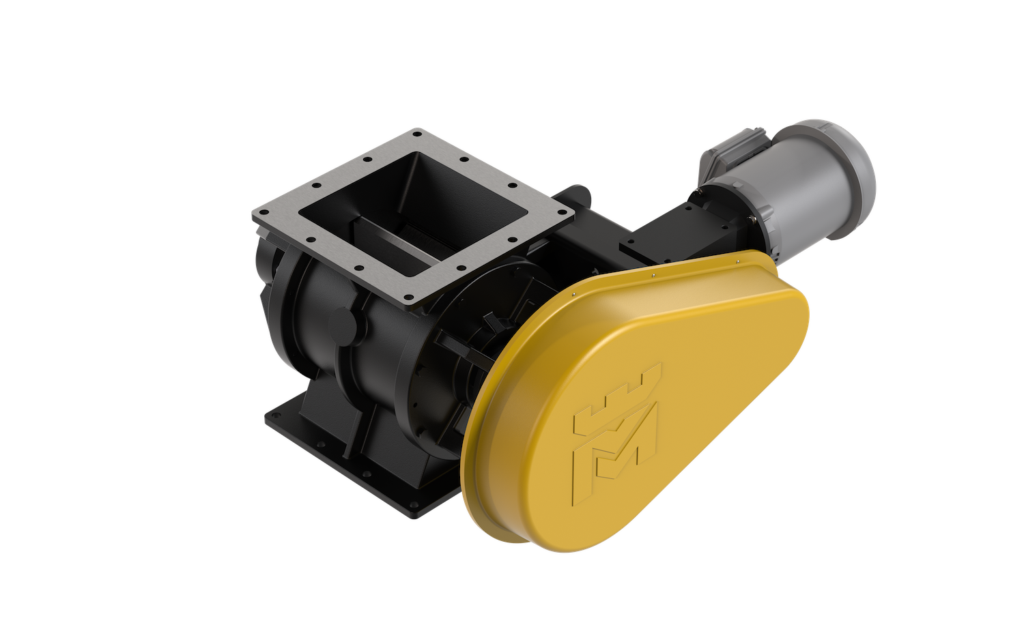

What Is a Rotary Valve Airlock?

A rotary airlock valve, often called a rotary airlock feeder or simply an airlock valve, is a mechanical device that controls the flow of bulk materials from one part of a system to another while maintaining the pressure differential between them. It typically consists of a rotating rotor with pockets that entrain material and deliver it through the valve from inlet to outlet. Importantly, as the rotor turns, it provides a sealing action that minimizes air leakage between compartments.

Why Rotary Airlocks Matter in Material Handling

Maintaining System Pressure and Efficiency

In pneumatic conveying systems, where materials are moved by vacuum or pressurized air, maintaining airflow balance is vital. Without an airlock, air can escape or enter uncontrollably, leading to air losses, reduced conveying efficiency, and potential system failure. A rotary airlock seals the interface between high-pressure and low-pressure zones, ensuring energy and performance are preserved.

Controlled Flow and Metering of Materials

Rotary airlocks not only serve as airflow barriers, but they also precisely control material flow. The rotor’s pockets deliver a consistent amount of material with each revolution, preventing surges, blockages, or uneven feed rates. This capability is critical in process industries where accurate dosing and continuous movement directly affect product quality and throughput.

Versatility Across Industries

Rotary airlocks handle a wide range of bulk solids, including powders, granules, pellets, and abrasive materials. They are used in food processing, pharmaceuticals, mining, chemical manufacturing, plastics, wood, pulp, and more. Their adaptability allows them to be tailored to different materials and pressures, making them indispensable across diverse applications.

Enhancing System Longevity

By selecting the proper configuration for the application, rotary airlocks reduce wear on downstream equipment and help extend overall system life. They also minimize maintenance interruptions by addressing common issues such as clogging and excessive vibration.

Meyer Industrial: The Gold Standard in Rotary Valve Airlocks

When it comes to industrial airlocks, Meyer HDX Heavy Duty Extra-Tough Rotary Airlock Valve leads the industry in performance and durability.

Why Meyer Industrial Airlocks Stand Out

- Proven Reliability and Engineering Excellence – Meyer Industrial has been manufacturing rotary airlocks with robust design and precision engineering for decades, earning a reputation as a global leader in the field. Our valves are known for superior craftsmanship and long service life, even in demanding environments.

- Built for Diverse Material Handling Needs – From standard rotary airlocks to heavy-duty blow-thru, side-entry, and wear-resistant models, Meyer offers solutions tailored to specific application requirements. These include options for abrasive materials and sanitary handling.

- Exceptional Performance Under Pressure – Meyer Industrial’s airlocks excel in pneumatic conveying systems, preserving pressure and vacuum levels and ensuring reliable material delivery between zones of different pressure. This reduces energy loss and improves overall system throughput and efficiency.

- Trusted Worldwide – With installations in 40+ countries and a broad range of customizable configurations, Meyer Industrial airlocks are trusted by engineers and plant managers worldwide for critical material-handling applications.

Rotary valve airlocks play a critical role in material handling systems by preserving vacuum pressure levels, controlling material flow, reducing waste, and boosting overall system efficiency. They serve as both a precision feeder and a pressure barrier, enabling smooth, reliable operation across a multitude of industries.

For plant operators seeking top-tier performance and durability, Meyer Industrial rotary airlocks are the best solutions on the market, offering engineering excellence, versatility, and operational reliability that keep material handling systems running at peak performance.