General Measure, a leading provider of weighing and packaging solutions, offers an advanced Packing Scale tailored for free-flow materials. There are two distinct control mechanisms of packing scale: servo motor control and pneumatic cylinder control. While both mechanisms are functional for managing the material gate operation during packing, their differences in precision, flexibility, and adaptability make a compelling case for servo motor-driven solutions in modern packing environments.

Servo Motor Control VS. Pneumatic Cylinder Control

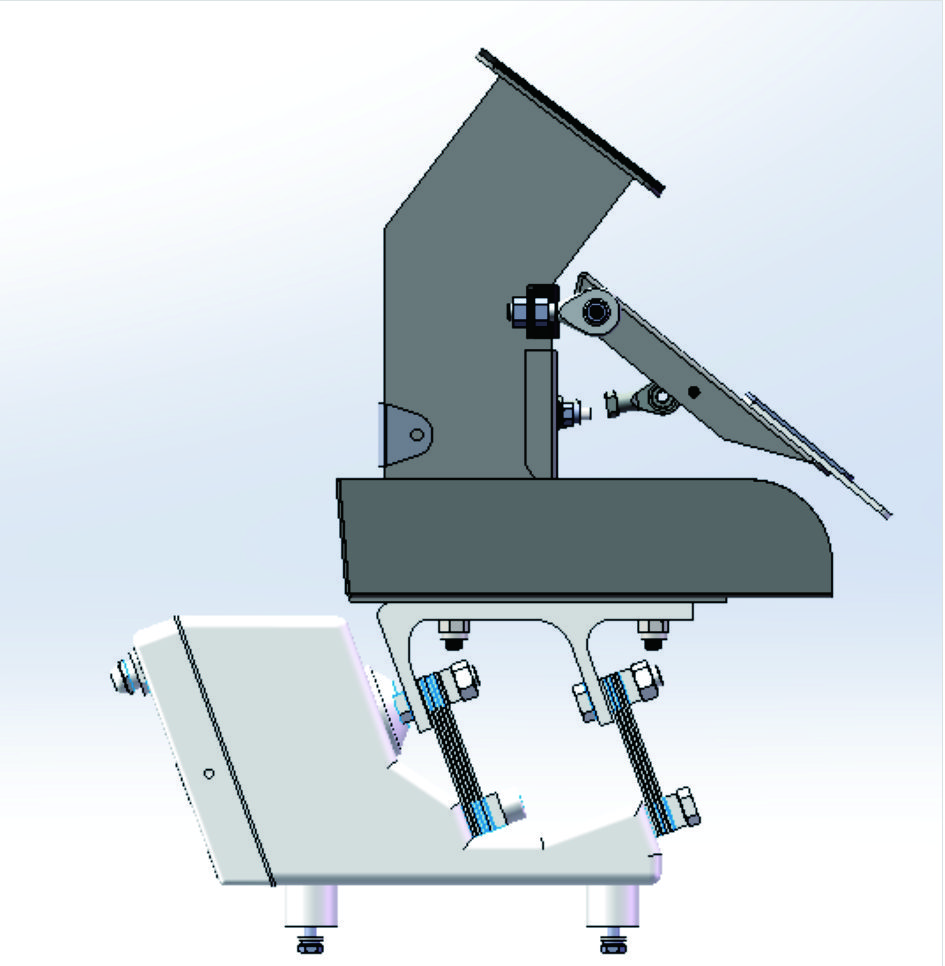

At the core of a packing scale’s performance is its ability to control the gate opening rate, directly impacting the material flow and, consequently, packing accuracy and speed.

1. Pneumatic Cylinder Control:

This traditional method uses compressed air to actuate a cylinder that opens or closes the gate. It has limited flexibility. Adjusting the open rate of the gate typically requires manual tuning by a technician. Due to this constraint, pneumatic systems are best suited for a narrow range of materials—those with similar density, particle size, and flow characteristics.

2. Servo Motor Control:

In contrast, the servo motor control system offers unparalleled precision and adaptability. The servo motor can regulate the gate opening rate across a wide range—from 1 to 10,000 pulses, with each pulse representing 0.0045 degrees of rotation. This fine level of control allows the gate opening to be digitally adjusted in real time, making it highly suitable for packaging a diverse variety of materials, including powders, granules, and small particles, each with different flow properties.

Why Servo Motor Control Is the Superior Choice

Here’s why General Measure’s servo motor-driven packing scale outperforms its pneumatic counterpart:

Highly Adjustable: With the ability to change the gate opening from 1 to 10,000 pulses, users can fine-tune the material flow to suit the specific characteristics of each product. This eliminates the need for physical intervention and adjustment by a technician.

Greater Versatility: The servo system supports multiple material types within the same packing line. Whether handling light, fine or heavier granules, or even powder, the servo motor adapts effortlessly to varying flow rates and densities.

Precision & Consistency: Digital control ensures repeatable results, reducing the margin of error in fill weights and improving overall packing accuracy.

Automation Integration: Servo motors are easily integrated into automated systems, offering real-time feedback and compatibility with smart factory environments.

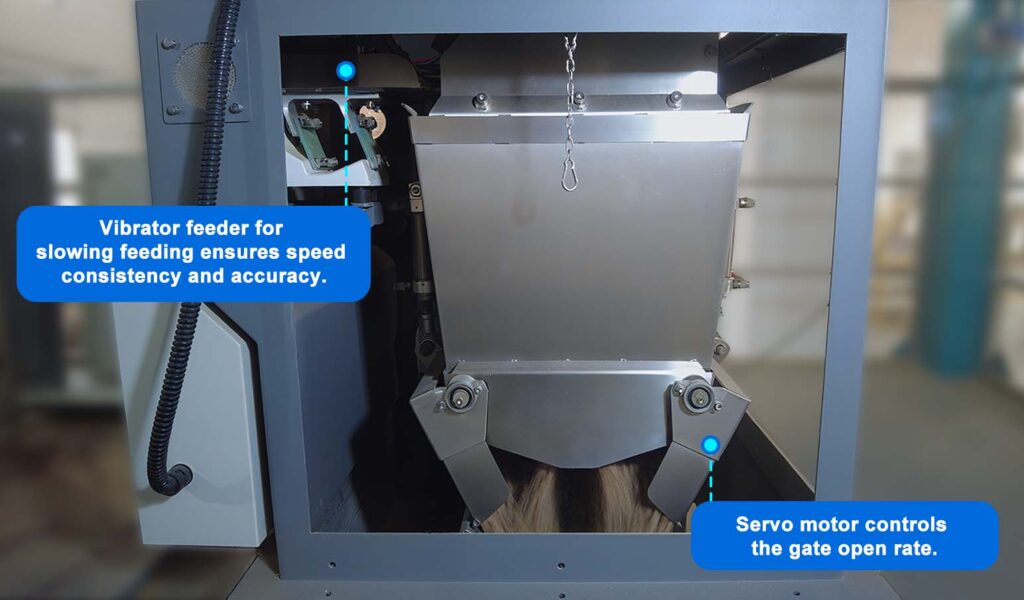

Enhanced Performance with Vibrator Feeder Integration

Considering the hopper gate opening rate is small when slow feeding, to solve the material’s poor fluidity and further elevate the performance of the packing scale, General Measure integrates a vibrator feeder into the system. This addition provides several advantages:

Flow Rate Stability: The vibrator feeder helps regulate the movement of materials through the gate, ensuring a consistent and even flow. This is especially useful for materials prone to bridging or clumping.

Faster and More Accurate: As the packing process transitions from fast to slow feeding, the vibrator ensures smoother and more controlled delivery, enhancing weighing speed and precision.

Improved Efficiency: By reducing the likelihood of blockages and ensuring uniform material flow, the vibrator feeder increases the overall packing speed without compromising accuracy.

The Result: High Accuracy, Speed, and Material Flexibility

Combining servo motor control with a vibrator feeder, General Measure’s packing scale delivers:

High Accuracy: Minimizing underfills and overfills, even with variable material types.

High Speed: Fast transition between feeding stages and quick material discharge.

Wide Compatibility: Effectively handles a broader range of materials compared to pneumatic-only systems.

Lower Maintenance: Less need for manual calibration or technician intervention.

Smart Control: Seamless integration with automated packing lines and data feedback systems.

General Measure’s innovation in packing technology—especially the integration of servo motor control and vibrator feeders—marks a significant step forward in packaging automation. For manufacturers looking to improve accuracy, speed, and flexibility, switching from pneumatic cylinder systems to servo-driven packing scales offers clear operational advantages.

By embracing these technologies, businesses can better accommodate the diversity of materials in modern production lines while maintaining consistency, reducing waste, and boosting productivity.

Let General Measure’s advanced packing scale be the smart choice for your precision packaging needs.