Traditional hose-and-clamp connectors often trap residue, leak product, and complicate cleaning – creating risks for contamination, allergen cross-contact, and regulatory non-compliance.

95% of the world’s top 20 food manufacturers understand this challenge and have switched to the industry-leading BFM® fitting flexible connector system which was developed to address these hygiene and safety concerns directly.

If you’re a food manufacturer who is still using old-style clamped connectors, it’s important to understand the core food safety challenges associated with traditional connectors – read on and you’ll also find out how BFM® fittings help solve every one of them!

Key Hygiene Challenges in Traditional Flexible Connectors

1. Contamination from Crevices and Product Traps

Clamp-style connectors have overlapping sleeves and external clamps that leave internal crevices where product can accumulate. In environments like milk powder or allergen-sensitive lines, these hidden pockets can harbour bacteria or allergens that survive cleaning and contaminate future batches.

Solution with BFM®: BFM® fittings feature an internally mounted, snap-fit design that creates a flush, crevice-free interior. This eliminates dead spaces where product or moisture can hide – a key requirement under 3-A hygienic design guidelines.

2. Leaks and Dust Emissions

Achieving a uniform seal with clamps is difficult, especially under vibration or pressure surges. Micro-leaks can release dust into the plant environment, compromising product safety, inviting pests, or even posing dust explosion risks.

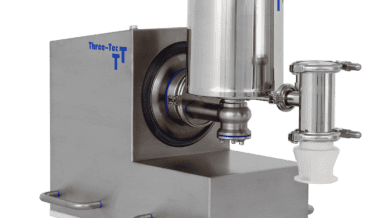

Solution with BFM® (shown far right): The patented cuff-and-spigot system in BFM® connectors creates a 100% sealed connection. Tests show they maintain integrity under pressure and prevent dust or product from escaping. Plants switching to BFM® report significantly cleaner environments and improved allergen control.

3. Difficult and Inconsistent Cleaning

Clamp systems are time-consuming to remove and reassemble, often requiring tools. This leads to longer downtimes and increases the risk of incorrect reinstallation – a hygiene and safety hazard.

Solution with BFM®: The tool-free design allows connectors to be removed and replaced in under 30 seconds, ensuring quick, error-proof changeovers.

Cleaning is easier, simplifying compliance with cleaning schedules, and dedicated CIP Wash Sleeves can also be provided to ensure thorough, fast, safe cleaning cycles.

4. Durability and Risk of Material Failure

Silicone connectors, especially when clamped, are prone to tearing under stress or vibration. Fragments of material can enter the product stream, causing contamination and costly downtime.

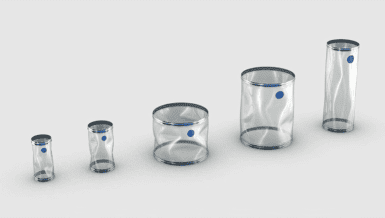

Solution with BFM®: BFM®’s Seeflex 040E polyurethane is tough, tear-resistant, and engineered for high flexing and abrasive applications. It’s also transparent, so operators can visually inspect for cleanliness or residue – something opaque silicone sleeves can’t offer.

5. Worker Safety and Foreign Object Risk

Tools used to tighten clamps can slip, injure operators, or drop components into product zones. Clamps may spring loose or wear out, increasing risk of sudden disconnection during operation.

Solution with BFM®: With no external hardware or tools, BFM® connectors reduce foreign object risk and improve ergonomic safety for maintenance crews. The standardized fit ensures consistent sealing every time.

Materials Matter: Silicone vs. Polyurethane

Silicone (left), while food-safe and heat-resistant, tends to degrade under stress and hides residues due to its opacity. It also builds static, which is dangerous in powder environments.

Polyurethane, particularly BFM®’s transparent Seeflex range (shown right), offers better abrasion resistance, visibility, and can be made anti-static for ATEX compliance. These properties make it ideal for dry, dusty, or allergen-sensitive lines.

The BFM® system’s hygienic design works hand-in-hand with material selection, ensuring long life, clear visibility, and electrostatic safety where needed.

Regulatory Compliance Built In

BFM® connectors are designed to meet or exceed food safety standards, including:

- EU Regulation 1935/2004 and 10/2011 – Safe migration limits and GMP compliance

- 3-A Sanitary Standards – Hygienic design and cleanability

- FDA (21 CFR 177) – Material safety for food contact

- USDA – Design and safety standards for dairy, meats & poultry processing

- GB – Chinese National Food Safety Standard for Plastic Materials and Articles in Contact with Foodstuffs

- ATEX Compliance – Static dissipation for explosive dust zones

This makes BFM® connectors audit-ready and simplifies compliance for food manufacturers during inspections and certification processes.

Real-World Benefits for Food Safety

- Reduced Cross-Contamination: In allergen-sensitive or multi-product lines, BFM® connectors prevent residual buildup and enable rapid changeovers, reducing allergen risk.

- Cleaner Plant Environments: Eliminating leaks means less airborne dust, fewer pest attractants, and better overall plant hygiene.

- Faster, Easier Cleaning: Quick disassembly supports more frequent and thorough sanitation, while clear walls enable visual confirmation of cleanliness.

- Fewer Contamination Incidents: Plants report fewer microbial hotspots and lower maintenance-related contamination risks after switching to BFM®.

- Improved Inspection Readiness: Certifications and material traceability simplify audits and demonstrate proactive hygiene management.

BFM® fitting is A Hygienic Design Upgrade That Delivers

Flexible connectors are often overlooked in food safety planning, but they’re pivotal to maintaining product purity and preventing contamination. Traditional hose-and-clamp designs introduce numerous hygienic challenges – crevices, leaks, difficult cleaning – that can compromise compliance and product integrity.

The BFM® fitting system was designed specifically to overcome these challenges. With crevice-free internal profiles, tool-free quick changes, leak-proof seals, and compliant, durable materials, BFM® connectors offer a clear food safety advantage.

In the age of FSMA, HACCP, and rising customer expectations, hygienic design is not optional. Upgrading to BFM® fitting flexible connectors helps food manufacturers proactively reduce risk, improve sanitation, and maintain regulatory compliance with confidence.