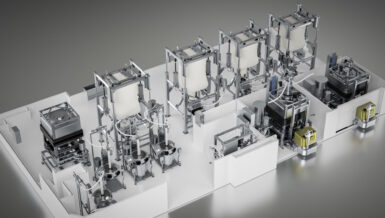

Designed with future scalability and operational excellence in mind, this facility reflects the highest standards in ingredient handling, process automation, and production traceability, made possible through Acmon Systems’ comprehensive turnkey solutions.

Key Technologies Supplied by Acmon Systems:

- Silo Storage & Raw Material Handling: Over 800 m³ of silo capacity, engineered for handling all types of flour—including whole wheat—without segregation. Real-time inventory monitoring and seamless distribution to up to five production lines.

- Ingredient Reception & Dosing: Six Big Bag unloading stations equipped with precise local weighing (<0.1%) and micro-ingredient stations for multiple ingredients per line. Dedicated receiving hoppers support bulk deliveries, optimized and automated by Acmon’s dosing technology.

- Quality & Safety Measures: Implementation of inline sieving and magnetic separators at critical transfer points, ensuring contamination-free processing—integrated into the overall automation system supplied by Acmon.

- Digitalization & Automation: Full process control through Acmon’s SCADA systems, featuring recipe management, batch reporting, and end-to-end traceability—delivering transparency, safety, and consistency.

The facility is designed to allow a 4x increase in throughput without compromising product quality or diversity — a testament to Acmon Systems’ future-proof engineering.

“Acmon Systems demonstrated a high level of professionalism throughout all stages of project design and implementation. We thank them very much for their flexibility and continuous support.” — George Delis Technical Director Stergiou Family

“We are proud to be the trusted partner in Stergiou Family’s vision to redefine the standards of modern baking. This project is a benchmark not just for Greece, but for the wider region,” — George Moshakis, Commercial Director, Acmon Group