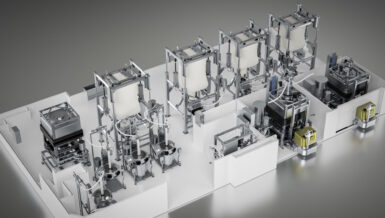

As part of this collaboration, we implemented a new eco-friendly production unit for waterproofing materials—acrylic, hybrid, and polyurethane—as well as ready-mixed paste render for external thermal insulation systems. The unit was designed with a strong focus on high production flexibility, consistent quality, and optimal efficiency.

At the same time, we installed a fully automated mortar production unit that enables the manufacturing of tile adhesive for insulation systems, repair mortars, and cement-based waterproofing products.

The entire process is dust-free, ensuring a high level of workplace protection while also contributing to the reduction of emissions and the overall environmental footprint of the facility.

For packaging, ultra-sonic valve technology was selected, guaranteeing complete and reliable sealing of the bags. A cleaning module was also integrated prior to palletizing, ensuring an excellent final product appearance with zero waste.

Through this project and the new infrastructure, Ravago takes a substantial step toward the future, strengthening its industrial capabilities and its potential for developing innovative products. At the same time, ACMON SYSTEMS reaffirms its commitment to delivering advanced, reliable, and technologically innovative solutions across a wide range of industrial applications.

Mr. Georgios Karlos stated:

“With flexibility, professionalism, and a deep understanding of our needs, Acmon Systems delivered two production units that fully meet our specific requirements, strictly adhering to our timelines and agreements. They are a steady and valuable partner in all our projects, standing by us even in the most demanding circumstances. We look forward to our future collaborations.”

ACMON SYSTEMS has successfully completed a major project for Ravago, making a significant contribution to the company’s strategy for progress, innovation, and the development of long-lasting value-driven solutions.

As part of this collaboration, we implemented a new eco-friendly production unit for waterproofing materials—acrylic, hybrid, and polyurethane—as well as ready-mixed paste render for external thermal insulation systems. The unit was designed with a strong focus on high production flexibility, consistent quality, and optimal efficiency.

At the same time, we installed a fully automated mortar production unit that enables the manufacturing of tile adhesive for insulation systems, repair mortars, and cement-based waterproofing products.

The entire process is dust-free, ensuring a high level of workplace protection while also contributing to the reduction of emissions and the overall environmental footprint of the facility.

For packaging, ultra-sonic valve technology was selected, guaranteeing complete and reliable sealing of the bags. A cleaning module was also integrated prior to palletizing, ensuring an excellent final product appearance with zero waste.

Through this project and the new infrastructure, Ravago takes a substantial step toward the future, strengthening its industrial capabilities and its potential for developing innovative products. At the same time, ACMON SYSTEMS reaffirms its commitment to delivering advanced, reliable, and technologically innovative solutions across a wide range of industrial applications.

Mr. Georgios Karlos stated:

“With flexibility, professionalism, and a deep understanding of our needs, Acmon Systems delivered two production units that fully meet our specific requirements, strictly adhering to our timelines and agreements. They are a steady and valuable partner in all our projects, standing by us even in the most demanding circumstances. We look forward to our future collaborations.”