To address these challenges, Advanced Cyclone Systems, SA (ACS) has developed Hurricane® high-efficiency cyclone systems designed specifically for tablet press dust control. These systems combine compactness, reliability, and outstanding separation efficiency with full compliance for GMP environments and Occupational Exposure Band (OEB) containment up to level 5.

The Science Behind Cyclone Optimization

Unlike conventional cyclones, often designed through empirical correlations or simplified Computational Fluid Dynamics (CFD) studies, ACS cyclones are the product of years of numerical optimization and fundamental research into particle agglomeration in turbulent fields.

Using its proprietary PACyc® simulation tool (Particle Agglomeration in Cyclones), ACS models the way submicrometric particles behave under real industrial conditions. Contrary to classical assumptions, fine particles—particularly those below 5 μm—tend to agglomerate with larger ones, increasing their effective size and, consequently, their collectability. The PACyc model captures these dynamics, allowing ACS to design cyclones that achieve efficiencies previously considered unattainable for dry separation devices.

The result is a set of patented geometries that minimize re-entrainment, optimize internal flow patterns, and maintain a low pressure drop. Each Hurricane cyclone is thus tailored for its specific process conditions: flow rate, particle size distribution, density, and temperature. This ensures maximum product recovery yield and minimum emissions with reduced CAPEX and OPEX compared to alternative filtration technologies.

Tablet Press and Dedusting Operations: A Critical Dust Source

Tablet compression and subsequent dedusting generate continuous flows of fine powder. In most facilities, this dust is drawn into a central aspiration system, combining streams from multiple presses into a common filter. While effective for air cleanliness, this centralized approach introduces several drawbacks:

- Loss of product traceability, since all waste is mixed before disposal.

- Cross-contamination risk, as residues from different formulations can mingle.

- Increased filter loading, leading to more frequent maintenance and higher running costs.

- Reduced accuracy in batch reconciliation, a key compliance requirement under GMP.

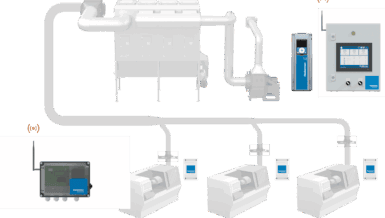

By installing localized cyclone separators at each tablet press line, these challenges can be overcome. Each cyclone captures the waste powder directly at the source, isolating it in a dedicated container. This makes it possible to determine precisely how much material each press generates as waste, facilitates safe disposal or potential reuse, and protects the central filtration unit from overload.

Case Example: Actavis Elizabeth LLC (Teva Pharmaceuticals)

A landmark project illustrating this approach took place at Actavis Elizabeth LLC, now part of Teva Pharmaceuticals. The facility faced difficulties managing fine dust emissions from several tablet press rooms connected to a single barrier filter. The inability to distinguish waste streams from individual presses complicated production accounting and quality assurance.

ACS was commissioned to design a customized solution. After laboratory analysis of powder samples and process parameters, the engineering team developed 10 Hurricane HR cyclone systems: eight units with 275 mm diameters for smaller presses and two larger units (400 mm) for high-capacity equipment

Constructed entirely in AISI 316L stainless steel and fitted with sight-glass catch pots and mobile support frames, each system could be quickly assembled and cleaned using tri-clamp fittings and quick clamps. The compact design offered 98 % capture efficiency at an average pressure drop of 1.8 kPa, fully meeting performance expectations

Following the success of the first installation in 2015, the client extended the order to the entire site. The result was improved powder containment, easier compliance with waste accounting regulations, and a substantial reduction in filter maintenance. The customer reported complete satisfaction with both performance and ease of operation.

Containment and Operator Safety

Modern pharmaceutical manufacturing demands equipment that safeguards both product and personnel. In tablet compression areas, powders may include potent APIs requiring OEB 2 or higher containment. ACS designs address these requirements through an array of built-in features:

- Safe-change catch pots, allowing product removal without dust release.

- Isolation valves, to disconnect containers safely during operation.

- Optional HEPA “police” filters, providing > 99.9 % total system efficiency.

- CIP (Clean-In-Place) readiness, enabling dust-free cleaning between batches.

These elements make Hurricane cyclones ideal for containment-critical environments. Their sealed design helps maintain cleanroom classification while avoiding the complexity and cost of fully contained isolator systems

ACS systems can thus function as either primary collectors, directly recovering product before central filtration, or as pre-separators, protecting HEPA filters and prolonging their service life. In both cases, they provide a highly reliable, maintenance-friendly solution that aligns with the strictest GMP and OEB standards.

Integration Flexibility

The modularity of ACS cyclone systems is another defining advantage. They can be integrated into local exhaust ventilation (LEV) lines, combined with dedusters, or mounted on mobile frames for flexible use across different production suites.

For processes involving recyclable powder, recovered material can be reintroduced into production after quality verification, improving yield and sustainability. Alternatively, the collected waste can be safely sealed for disposal.

Each system is designed for user convenience, with break-apart construction and quick-connect fittings for rapid disassembly. This ease of handling reduces downtime during batch changes and facilitates preventive maintenance without the need for specialized tools.

Performance and Efficiency

ACS cyclones demonstrate exceptional performance when compared to traditional designs. For example, the Hurricane HR Ø275 model used in tablet press applications typically handles flow rates around 45 m³/h at room temperature, achieving collection efficiencies between 96 % and 99 %

These results are achieved without relying on filter media, meaning there are no consumables to replace and no risk of filter blinding. The systems operate continuously, with stable efficiency even under fluctuating process conditions. This reliability translates into consistent compliance with emission limits and predictable operation costs.

Cyclone Separation Process

The working principle remains elegantly simple yet scientifically refined. The dust-laden air enters tangentially into the cyclone, setting up a high-velocity vortex. Centrifugal forces drive the heavier particles toward the wall, where they lose momentum and descend into the catch pot. Cleaned air spirals upward through the core and exits to the extraction system.

This inertial separation process is entirely mechanical—no moving parts, filters, or sprays—making it ideally suited for continuous pharmaceutical environments where uptime, cleanliness, and repeatability are paramount.

Beyond Tablet Press: Wider Applications in Pharma

While tablet press dedusting is a primary use case, ACS cyclone technology extends across multiple powder handling stages: from fluid-bed dryers and spray dryers to capsule filling, mixing, and packaging lines. In each of these applications, the same core advantages apply—low maintenance, contained operation, and high recovery yield.

With more than 400 installations worldwide, ACS has become a trusted partner for major pharmaceutical companies including Teva, Merck, Lonza, Hovione, and Ipsen, helping them improve environmental performance and production efficiency.

Conclusion

In an era when pharmaceutical manufacturers are under constant pressure to enhance sustainability, ensure safety, and comply with tightening regulations, cyclone-based powder recovery provides a smart, economical solution.

Advanced Cyclone Systems’ Hurricane® and ReCyclone® solutions stand out as proven technologies—robust, efficient, and tailored for the specific challenges of tablet press and dedusting dust control. Through scientific design, precision manufacturing, and a deep understanding of pharmaceutical containment needs, ACS helps the industry capture value from every particle, literally turning waste into opportunity.