Our integrated approach leverages multiple layers of safety, combining options for early detection and combustible concentration reduction with optimized deflagration vents to safeguard next-generation BESS installations.

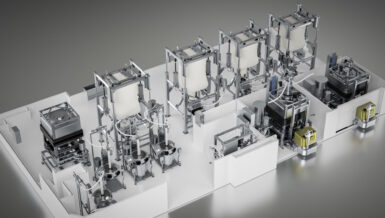

REMBE® offers a comprehensive range of products that help safeguard BESS against explosions. Three distinct product series enable optimal solutions for any BESS installation, each bringing unique advantages to your project.

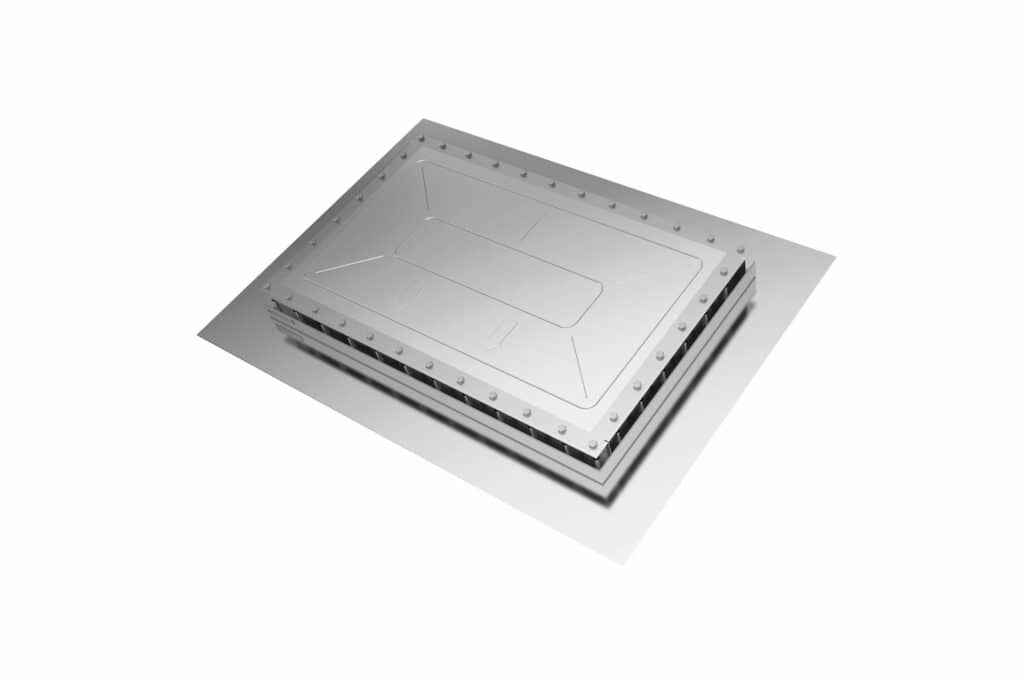

The BESS Core Venting Series delivers efficient roof venting through our proven EGV products. Engineering excellence meets customization – each product is precisely tailored to customer specifications, from size and burst pressure to insulation materials and properties. This series offers proven protection with attractive volume pricing.

Innovation takes center stage in the BESS Smart Venting Series with BESS.TGV, our revolutionary deflagration vent for BESS enclosure sides. The patented TargoVent principle deflects explosion effects upward to a safe location. By moving explosion protection from roof to container sides, BESS.TGV eliminates concerns about snow loads and hail impact while freeing up valuable roof space. This creates new possibilities for BESS configuration, such as vertically stacked installations. With a uniquely slim profile, BESS.TGV seamlessly integrates into any BESS enclosure.

The BESS Premium Venting Series represents our latest breakthrough in explosion protection. As pioneers of flameless venting technology, REMBE® has developed BESS.Q.Vent – the first flameless vent specifically engineered for BESS applications. By eliminating external flames and minimizing thermal and pressure effects, BESS.Q.Vent enables safe installation of BESS in indoor locations and other sensitive environments.

Enhancing this comprehensive protection portfolio, advanced detection systems provide an extra layer of safety. Our Hotspot and GSME sensors detect critical faults before they escalate: Hotspot through precise thermal monitoring, and GSME through multi-gas detection. This early warning capability enables early intervention before potential issues develop into thermal runaway events, completing our integrated approach to BESS safety.

Beyond our products, REMBE® is your global consulting and engineering partner throughout your entire project. Our explosion protection experts and external engineering partners work closely with you to determine the optimal safety solution for your specific requirements.

What contribution can we as REMBE® make to improving safety?

At REMBE® we believe that ensuring the safety of Battery Energy Storage Systems (BESS) requires more than just high-performance components. As a family-owned company with over five decades of experience in explosion safety, we offer a holistic approach that combines in-depth technical knowledge, practical testing expertise, and a strong understanding of regulatory frameworks.

From the earliest stages of project planning, we work closely with stakeholders to assess specific risks and define tailored safety strategies. This includes technical evaluations such as explosion-related calculations of venting areas, according to national and international standards. The REMBE® Alliance also includes the expertise of an independent testing laboratory, the REMBE® Research+Technology Centre GmbH. In addition to the testing and validation of protective measures at the accredited test centre, we are able to carry out fire and explosion tests with prototypes under practical conditions. The testing of explosion pressure resistance or flame penetration tests on battery housings and the development of flameless venting systems to prevent explosive flames and flying debris can also be carried out here.

Our portfolio includes a wide range of certified solutions, which are continuously refined and adapted to meet evolving industry requirements. Beyond the technology itself, we see ourselves as a long-term partner, providing advice, support and expertise at every stage of the project – from concept to product and implementation and beyond.

In this way, REMBE® contributes to safer, more reliable energy infrastructures – today and into the future.

About REMBE – the REMBE Alliance introduces itself

Most people associate REMBE with REMBE GmbH Safety+Control, the specialist for explosion safety and pressure relief worldwide. The company offers customers cross-industry safety concepts for plants and equipment. All products are engineered in Germany and meet the requirements of national and international regulations. REMBE customers include market leaders in various industries, including the food, timber, chemical and pharmaceutical industries.

The company’s engineering expertise is based on over 50 years of application and project experience. As an independent, owner-managed family business, REMBE combines expertise with the highest quality standards and is involved in various specialist committees worldwide. Short coordination paths allow for quick reactions and customer-specific solutions for all applications, from standard products to high-tech special designs.

In addition to REMBE GmbH Safety+Control (www.rembe.de) with around 350 employees worldwide – headquartered in Brilon (Hochsauerland, Germany) – and numerous subsidiaries in Italy, Finland, Brazil, USA, China, Dubai, Singapore, South Africa, Japan and Korea, four other companies operate under the REMBE umbrella brand:

- REMBE Research+Technology Center GmbH (www.rembe-rtc.de)

- REMBE Advanced Services+Solutions GmbH (www.rembe-services.de)

- REMBE Kersting GmbH (www.rembe-kersting.de)

- REMBE FibreForce GmbH (www.argusline.de)