Potential Risks

Due to their position in the process, Hammer Mills are often subjected to foreign objects such as stones, tramp metal, and other debris. Objects entering the grinding zone are impacted by the “hammers” and can produce sparks, creating a potential ignition source. Because Hammer Mills typically operate 24/7, they are subject to bearing failures—another significant source of ignition.

Challenges

Proper operation requires constant volumes of air to sweep through the mill requiring air exhaust systems such as bin vent filters, cyclones, or baghouse filters. Air intake is done either through the product feeder housing or through louvers in the mill itself. Both of which present significant isolation challenges. Milled product is taken away from the mill by either gravity into a “plenum” (hopper) or by a pneumatic airlift. Each method presents its unique challenges.

Boss Products’ Solutions

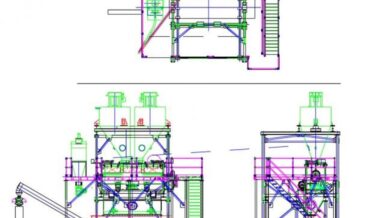

Plenum System Active Protection

- Sensors are located in the plenum

- Isolation cannisters located in the feeder area and dust collection exhaust or bin vent

- Suppression in the plenum

Plenum System Passive Protection

- Explosion vents (or flameless explosion vents located in the plenum and bin vent (if applicable)

- Exhaust duct isolation with Vigiflap (if applicable)

- Spark Detection/extinguishing in plenum)

- Explosion isolation rotary valve in plenum Discharge

Airlift System Active Protection

- Sensors located in the mill discharge area & filter receiver

- Isolation cannisters in the mill feeder area, airlift inlet duct, airlift piping, inlet and outlet of filter receiver

- Suppression in the hammer mill body and filter receiver

- Explosion isolation rotary valves in filter receiver hopper discharge

Airlift System Passive Protection

- Explosion isolation valve VF on airlift inlet duct & airlift pipe (depending on product and loading) & filter receiver clean air ducting if returned air

- Spark detection/extinguishing on airlift pipe

- Explosion venting on filter receiver

- Explosion isolation rotary valves in filter receiver hopper discharge