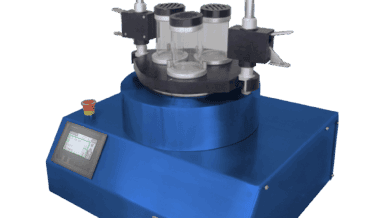

The system consists of two concentric dosing elements:

- A rotor, which controls the initial product flow, and

- A screw (auger), which ensures the final micro-dosing.

Both elements are independently driven, providing a unique combination of high accuracy without compromising discharge speed. In conventional dosing systems, higher precision often means lower throughput. Rotometering optimizes both parameters, delivering controlled and continuous product fractioning.

SteriValves’ system is based on full traceability, allowing the origin, production path, and related events of each product to be tracked. This provides added value: every product, accessory, or component can be easily identified for replacement or maintenance.

Available in ATEX-certified and FDA-compliant versions, the Rotometering valve is suitable for installations such as BIN bottoms, Big-Bag discharge, or process machinery. The auger is customizable according to product characteristics, ensuring flexibility and protection of product quality.

Rotometering represents a key technology for solid process automation, reducing manual intervention and improving operational efficiency.