This is where HETHON has made its mark for over 50 years with innovative total solutions. Their technologies – from flexible wall feeders to integrated scales and control cabinets – ensure that mixtures remain homogeneous, fragile powders are handled gently, and production processes stay hygienic and reliable.

With the HETHON flexible wall feeders, the company elevates process optimization in the food, pharmaceutical, chemical, and plastics industries to a whole new level. This article explains how the technology works, why it is so effective, and how it helps companies future-proof their mixing and dosing processes.

The Challenge After Mixing: Segregation and Process Disruptions

Many production facilities invest heavily in high-performance mixers and blenders to create a homogeneous mixture. But once the mixture is transported or dosed, segregation often becomes an issue. Differences in particle size, density, or shape can cause heavier or larger particles to separate from lighter ones. This challenge is particularly common in:

- Vibrating transport systems

- Sharp bends in pipelines

- Traditional dosing systems with rigid walls and rotating mechanisms

The result? Batches that no longer meet product specifications, with variations in taste, texture, or functionality. Ultimately, this leads to higher costs due to waste and rework. For industries with strict quality standards – such as food and pharmaceuticals – these consequences can be serious.

HETHON’s Answer: A Total Solution

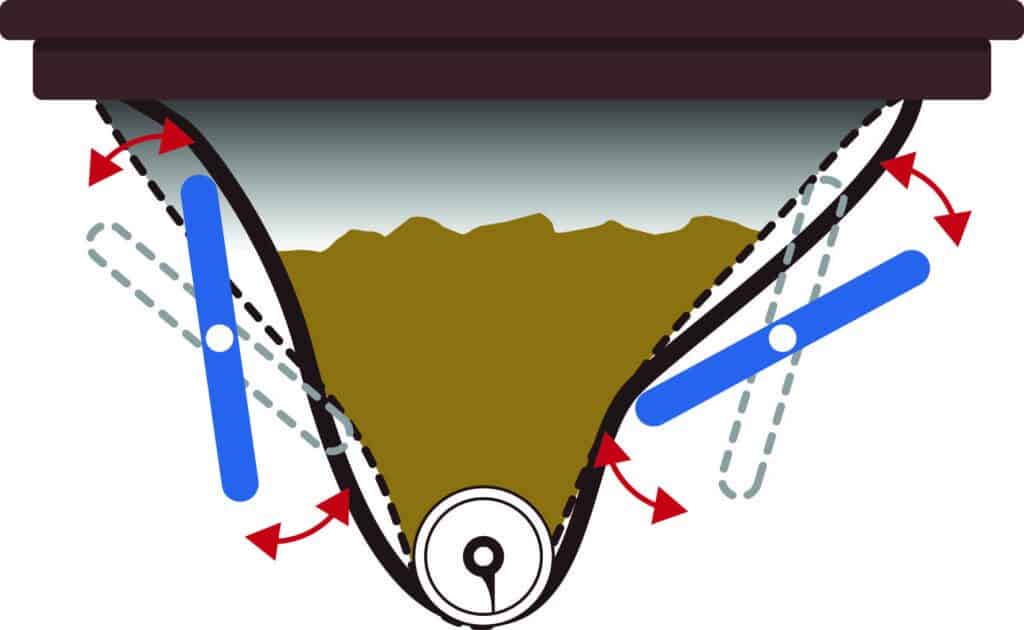

The HETHON flexible wall feeder offers a unique and proven solution. At the heart of this feeder is a flexible polyurethane (PU) wall that is gently “massaged” from the outside by actuators. This innovative operating principle prevents:

- Bridging and rat-holing

- Internal friction and turbulence that can lead to segregation

- Shocks and vibrations that cause particle separation

Since the mixture is not exposed to mechanical movements, its homogeneity is maintained from mixer to end point.

But HETHON goes beyond feeders alone. By integrating scales and control cabinets, the company provides complete systems for both gravimetric and volumetric dosing. This means: one supplier, one solution, and seamless alignment between hardware and control.

Gravimetric and Volumetric Dosing: Always Consistent

HETHON offers both gravimetric and volumetric dosing solutions, tailored to the specific requirements of each process.

- Volumetric feeding provides a reliable method for handling larger volumes, maintaining a consistent mass flow.

- Gravimetric feeding (with integrated scales) delivers extremely precise dosing based on weight – essential for applications where even minor deviations are unacceptable.

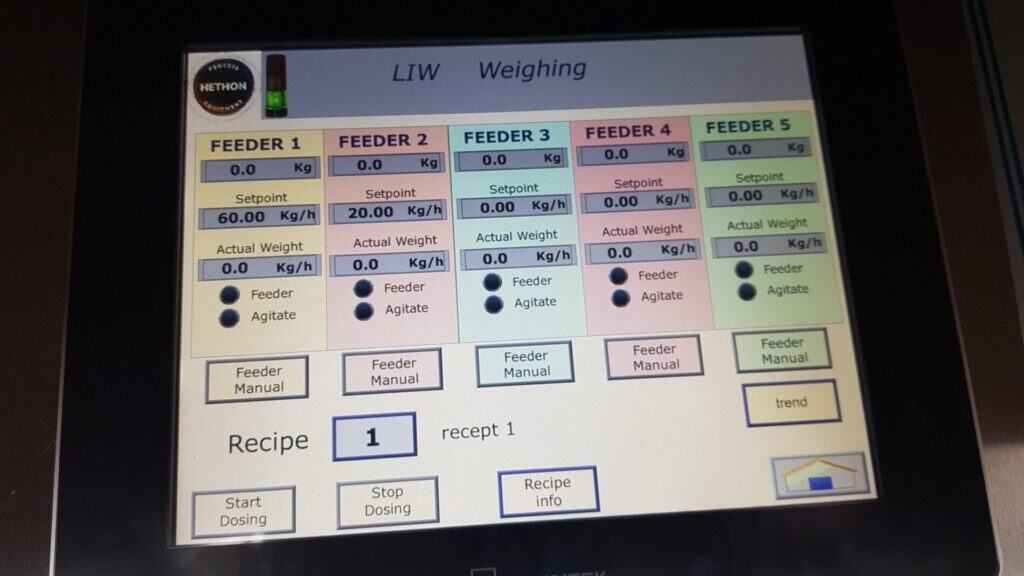

Loss-In-Weight (L.I.W.) Feeding: Precision at Every Step

HETHON’s gravimetric systems are based on the Loss-In-Weight (L.I.W.) principle, delivering the highest accuracy in dosing applications. By continuously monitoring the weight of the feeder and its contents, the system adjusts the feed rate in real time to ensure a constant mass flow – even when material properties or levels in the hopper change.

This approach offers several benefits:

- High accuracy – Essential for formulations with strict tolerances

- Automatic compensation for bulk density changes, bridging, or rat-holing

- Fast response time thanks to integrated load cells and smart control algorithms

The L.I.W. technology is fully integrated with HETHON’s flexible wall design, which eliminates internal friction and mechanical disturbances. The result: consistent product quality and optimal process control.

The control cabinets from HETHON ensure user-friendly and safe operation. They support all functions of the feeder and scale, giving operators real-time insights into their processes.

Hygiene Without Compromise: Cleaning-In-Place (CIP)

Hygiene is critical in the food and pharmaceutical industries. That’s why all HETHON systems are fully designed for Cleaning-In-Place (CIP). This means that internal walls and critical components can be cleaned thoroughly and automatically – without disassembly. The result: reduced downtime, less manual intervention, and consistent hygiene.

Case Study: Bakery Mixes Without Segregation

A manufacturer of bakery mixes was facing quality issues. Their blend of fine flour, sugar, and baking powder would segregate during dosing, causing some batches to lack sufficient leavening agent. After installing a HETHON system – consisting of flexible wall feeders, integrated scales, and a control cabinet – the mixture remained completely homogeneous throughout the process.

Thanks to the gentle massaging of the flexible wall and the constant, even discharge, they achieved:

- Improved batch consistency

- 25% reduction in product rejects

- More stable production with less downtime

Process Optimization in Practice

Preventing segregation and blockages brings clear benefits:

- Higher product quality – Every batch meets the same high standard

- Reduced downtime – No manual interventions needed

- Lower costs – Less waste and rework

- More hygienic processes – Thanks to CIP cleaning and closed systems

By offering feeders, scales, and controls as an integrated total solution, HETHON helps companies optimize production processes and prepare for the future.

About HETHON

HETHON Nederland BV has been a specialist in dosing and conveying systems for powders and granulates for over 50 years. The company develops and supplies solutions for the food, pharmaceutical, chemical, and plastics industries. With their flexible wall feeders, integrated scales, and control cabinets, HETHON provides unique technology for reliably, hygienically, and segregation-free dosing – even for the most challenging powders.

Visit www.hethon.nl for more information and applications.