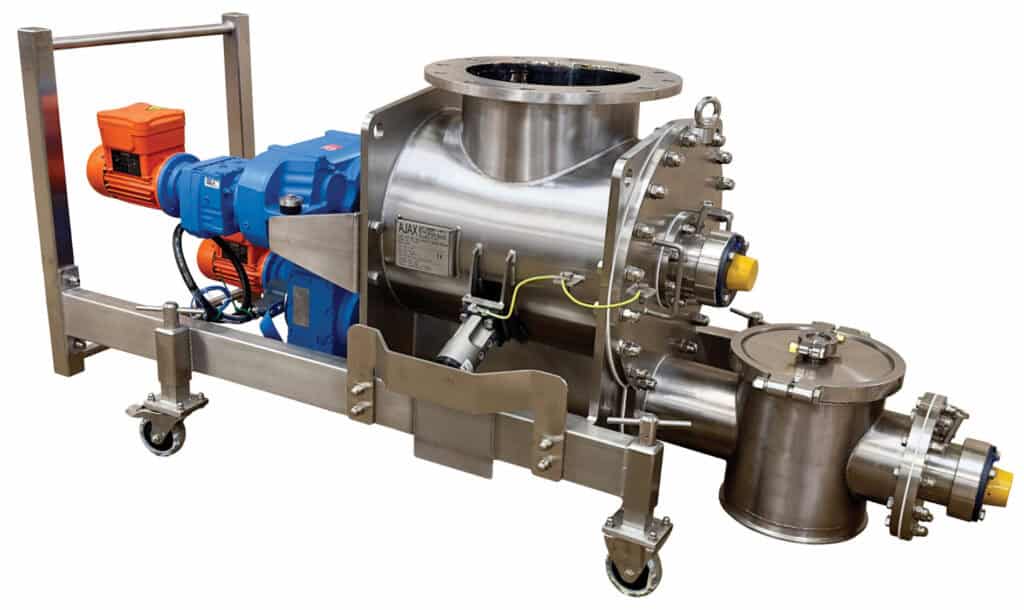

After conducting powder flow tests to determine the material’s handling characteristics, Ajax designed the fully polished stainless-steel agitated feeder to provide a reliable and controlled feed to downstream equipment. Powder is held in the agitated feeder’s hopper section, and the agitator promotes flow into the feed screw without compacting the powder.

“AJAX designed a robust feeder to suit the requirements and communicated well throughout design, fabrication, testing and delivery,” said Gerard O’Mahony, Mechanical Engineer, Sterling Pharma Solutions.

Commenting, Lewis Shaw, senior technical engineer at Ajax Equipment, said, “Pharmaceutical standards are some of the most demanding in solids handling but Ajax has over five decades of experience delivering high specification machines. In this case, the agitated feeder’s design and internal and external high specification polished finish were critical for excellent powder slip as well as making sterilization easier for the clean-in-place system. The exceptional mirror polish construction and individual geometry of the auger ensures the performance of the machine. While the mobile frame adds agility and flexibility of location should the requirement arise.”

What is an agitated screw feeder? How does it help with powder handling?

Prolonged storage times affect the condition of most materials. Fine cohesive powders or filter cakes, are prone to compaction, a condition which is detrimental to handling and therefore unsuitable for further processing. An agitated screw feeder can relieve these materials from over compaction with ‘active’ storage, which can maintain powder in a condition ready for use over prolonged periods of time.

The agitated screw feeder has three main components, the screw feeder, the agitator and the hopper. The screw auger design in the feeder is critical to performance and reliability; its geometry is vital in establishing and maintaining accurate and controlled feed rates of material into the next stage or processing.

The agitator has two prime functions; it disrupts material compaction to maintain a ‘live’ product flow condition through gentle agitation; in addition, the rotating action positively encourages material into the screw auger region to maintain a constant material presence.

The hopper section of an agitated feeder is notably different from a gravity flow hopper, usually due to the deep U profile being designed to suit the sweep of the agitator, however, sometimes a cylindrical profile is used depending upon the material, and the volumetric capacity requirements.

For more information on Ajax Equipment agitated screw feeders or pharmaceutical standard equipment call +44(0)1204 386723, email: sales@ajax.co.uk and visit www.ajax.co.uk.