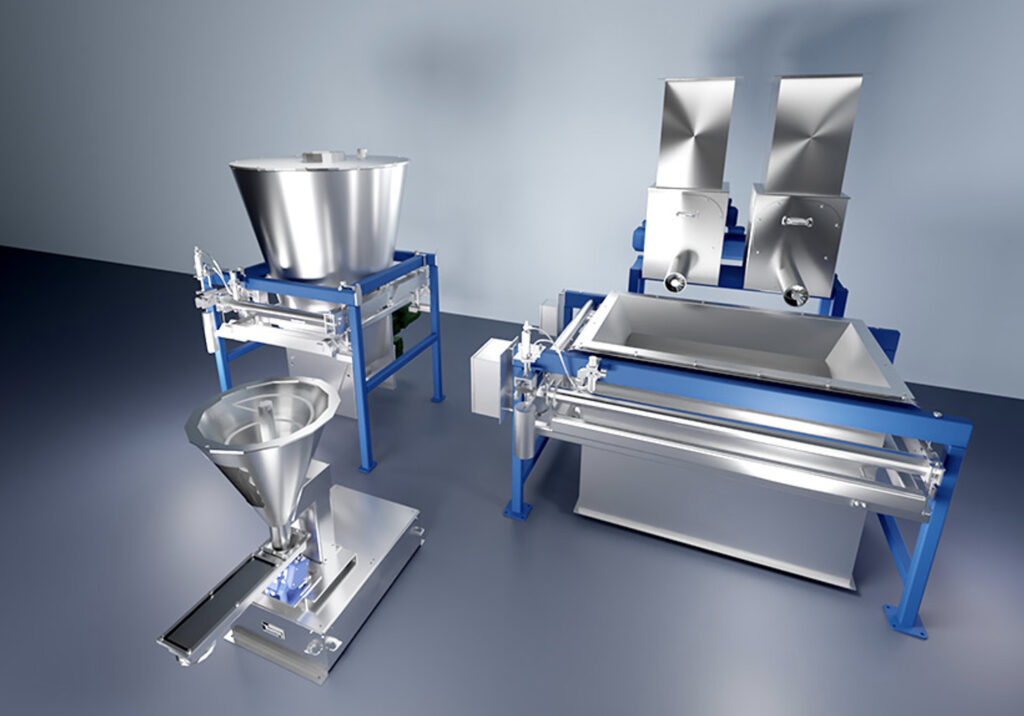

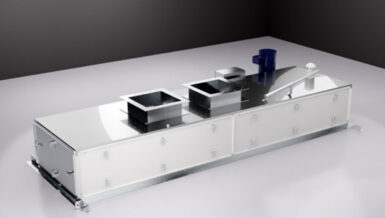

All Thayer Scale feeders offer integrated material agitation zones, specialized auger or vibratory tray designs, and a wide range of proprietary feed algorithms to ensure reliable feeding of difficult materials. When paired with one of Thayer Scale’s rugged, counterbalanced platform or cable scales, the combination is a robust gravimetric feeding solution that integrates seamlessly into existing plant processes.

Thayer Scale’s loss-in-weight feeders incorporate a volumetric feeding subsystem designed to provide consistent, reliable metering of the target material at desired flow rates. (Flow rates may be as low as two grams/minute and as high as 100,000 pounds/hour.) A fully mass-counterbalanced platform or cable scale designed to provide maximum signal and ensure accurate, reliable weight measurement in the most challenging operating conditions is paired with the most appropriate volumetric feeder for the specific application. Thayer Scale offers a powerful set of proprietary add-on accessories designed to solve problematic flow issues, such as bridging, flushing, adhesion, and cohesion. In addition, its instrumentation has powerful software routines specifically aimed at optimizing a feeder’s performance, such as output compensation, disturbance control, linearization, density compensation during refill, temperature compensation, and automated calibrations.

Loss-in-Weight Feeder Features:

- Extended operating range

- Durable scales that withstand abuse

- A single load cell that can be accessed and/or replaced without removing the feeder/weigh hopper

- Flexible mounting options: floor-mounted, rotating, stationary, wheeled, forklift-based, suspended

- Fast access for cleaning

- Wide range of screw augers that can be changed without tools

- Damage-free handling of delicate and/or fragile materials on vibratory trays